Question: How can I do question 2 on excel. SUMMARY Capacity management is the focus of this chapter. We show how the capacity- planning process extends

How can I do question 2 on excel.

How can I do question 2 on excel.

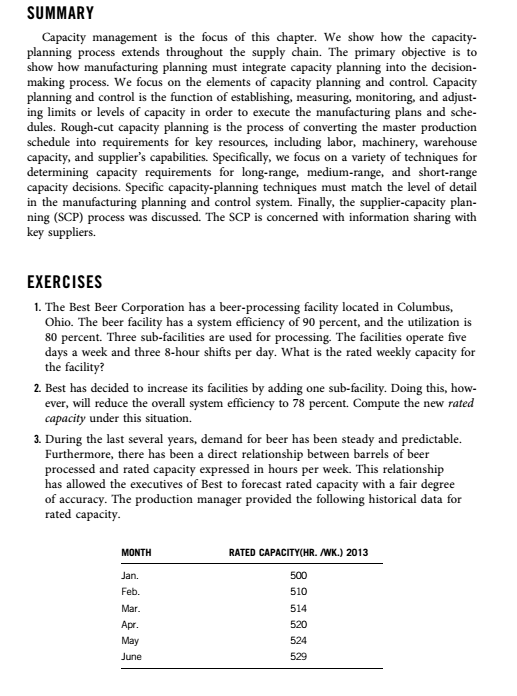

SUMMARY Capacity management is the focus of this chapter. We show how the capacity- planning process extends throughout the supply chain. The primary objective is to show how manufacturing planning must integrate capacity planning into the decision- making process. We focus on the elements of capacity planning and control. Capacity planning and control is the function of establishing, measuring, monitoring, and adjust ing limits or levels of capacity in order to execute the manufacturing plans and sche- dules. Rough-cut capacity planning is the process of converting the master production schedule into requirements for key resources, including labor, machinery, warehouse capacity, and supplier's capabilities. Specifically, we focus on a variety of techniques for determining capacity requirements for long-range, medium-range, and short-range capacity decisions. Specific capacity-planning techniques must match the level of detail in the manufacturing planning and control system. Finally, the supplier-capacity plan ning (SCP) process was discussed. The SCP is concerned with information sharing with key suppliers. EXERCISES 1. The Best Beer Corporation has a beer-processing facility located in Columbus, Ohio. The beer facility has a system efficiency of 90 percent, and the utilization is 80 percent. Three sub-facilities are used for processing. The faciliies operate five days a week and three 8-hour shifts per day. What is the rated weekly capacity for the facility? 2. Best has decided to increase its facilities by adding one sub-facility. Doing this, how- ever, will reduce the overall system efficiency to 78 percent. Compute the new rated capacity under this situation. 3. During the last several years, demand for beer has been steady and predictable. Furthermore, there has been a direct relationship between barrels of beer processed and rated capacity expressed in hours per week. This relationship has allowed the executives of Best to forecast rated capacity with a fair degree of accuracy. The production manager provided the following historical data for rated capacity RATED CAPACITY(HR. /WK.) 2013 500 510 MONTH Jan. Feb. Mar Apr May June 520 529 SUMMARY Capacity management is the focus of this chapter. We show how the capacity- planning process extends throughout the supply chain. The primary objective is to show how manufacturing planning must integrate capacity planning into the decision- making process. We focus on the elements of capacity planning and control. Capacity planning and control is the function of establishing, measuring, monitoring, and adjust ing limits or levels of capacity in order to execute the manufacturing plans and sche- dules. Rough-cut capacity planning is the process of converting the master production schedule into requirements for key resources, including labor, machinery, warehouse capacity, and supplier's capabilities. Specifically, we focus on a variety of techniques for determining capacity requirements for long-range, medium-range, and short-range capacity decisions. Specific capacity-planning techniques must match the level of detail in the manufacturing planning and control system. Finally, the supplier-capacity plan ning (SCP) process was discussed. The SCP is concerned with information sharing with key suppliers. EXERCISES 1. The Best Beer Corporation has a beer-processing facility located in Columbus, Ohio. The beer facility has a system efficiency of 90 percent, and the utilization is 80 percent. Three sub-facilities are used for processing. The faciliies operate five days a week and three 8-hour shifts per day. What is the rated weekly capacity for the facility? 2. Best has decided to increase its facilities by adding one sub-facility. Doing this, how- ever, will reduce the overall system efficiency to 78 percent. Compute the new rated capacity under this situation. 3. During the last several years, demand for beer has been steady and predictable. Furthermore, there has been a direct relationship between barrels of beer processed and rated capacity expressed in hours per week. This relationship has allowed the executives of Best to forecast rated capacity with a fair degree of accuracy. The production manager provided the following historical data for rated capacity RATED CAPACITY(HR. /WK.) 2013 500 510 MONTH Jan. Feb. Mar Apr May June 520 529

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts