Question: How do you calculate the cost for the aggregate plan in Question 1? 30.01923. shipped at 40 per case 4. Inventory carrying cost is estimated

How do you calculate the cost for the aggregate plan in Question 1?

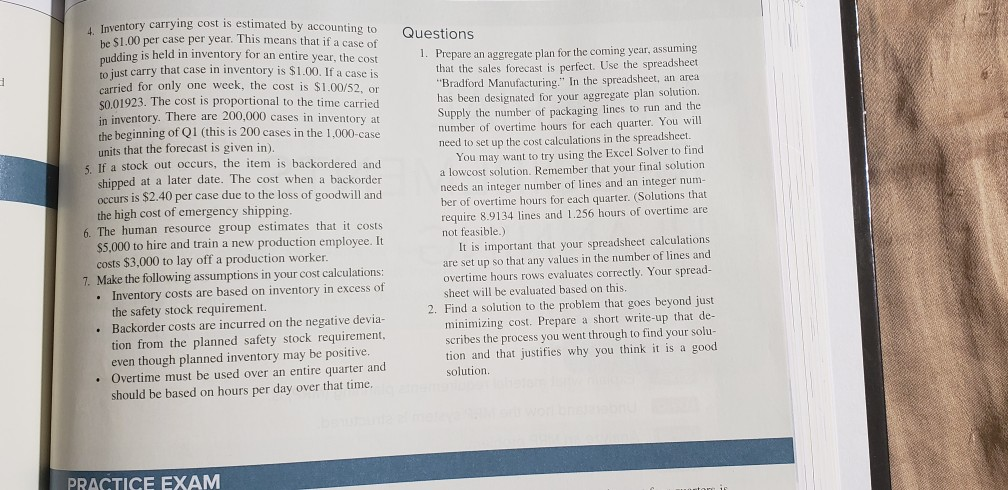

30.01923. shipped at 40 per case 4. Inventory carrying cost is estimated by accounting to be $1.00 per case per year. This means that if a case of pudding is held in inventory for an entire year, the cost to just carry that case in inventory is $1.00. If a case is carried for only one week, the cost is $1.00/52, or The cost is proportional to the time carried in inventory. There are 200,000 cases in inventory at the beginning of Q1 (this is 200 cases in the 1,000-case units that the forecast is given in). 5. If a stock out occurs, the item is backordered and a later date. The cost when a backorder occurs is $2.40 per case due to the loss of goodwill and the high cost of emergency shipping, 6. The human resource group estimates that it costs $5,000 to hire and train a new production employee. It costs $3,000 to lay off a production worker. 7. Make the following assumptions in your cost calculations: Inventory costs are based on on inventory in excess of the safety stock requirement. Backorder costs are incurred on the negative devia tion from the planned safety stock requirement, even though planned inventory may be positive. Overtime must be used over an entire quarter and should be based on hours per day over that time. Questions 1. Prepare an aggregate plan for the coming year, assuming that the sales forecast is perfect. Use the spreadsheet "Bradford Manufacturing." In the spreadsheet, an area has been designated for your aggregate plan solution. Supply the number of packaging lines to run and the number of overtime hours for each quarter. You will need to set up the cost calculations in the spreadsheet. You may want to try using the Excel Solver to find a lowcost solution. Remember that your final solution needs an integer number of lines and an integer num- her of overtime hours for each quarter. (Solutions that require 8.9134 lines and 1.256 hours of overtime are not feasible. It is important that your spreadsheet calculations are set up so that any values in the number of lines and overtime hours rows evaluates correctly. Your spread- sheet will be evaluated based on this, 2. Find a solution to the problem that goes beyond just minimizing cost. Prepare a short write-up that de- scribes the process you went through to find your solu- tion and that justifies why you think it is a good solution PRACTICE EXAM The pudding is shipped to the grocers from the non Your immediate task is to prepare an aglino the coming year. The technical and economie foto beronvertime hours for cach quarter (Solutions Tel.9154 Ines and 1756 hours of overtime are warehouses based on orders taken by the salespeople must be considered in this plan are shown next Forecast Demand by Quarter (1,000 Casei 3.000 2.500 the high cost of emergency shopping 6. The human resource group estimates $5,000 to hire and train a new product costs $3,000 to lay off a production worden + Make the following assumptions in your com Inventory costs are based on investory in excess the safety stock requirement . Backorder costs are incurred on the negative devis tion from the planned safely stock recuiremini even though planned inventory may be positive, Overtime must be used over an entire quarter ind should be based on hours per day over the time It is important that your spreadsheet calculations 30 stup so that any values in the number of lines and overtime houtstows evaluates correctly. Your spread sheet will be evaluated based on this 2. Find a solution to the problem that goes beyond just minimizing cost, Prepare a short write up that de- scribes the process you went through to find your solu tion and that justifies why you think it is a good solution 2.000 1.500 1.00 500 PRACTICE EXAM 0 Ist (1-13) (27-39) 4th (40-52) Next Year The Situation You are the operations manager for a manufacturing plant that produces pudding food products. One of your important responsibilities is to prepare an aggregate plan for the plant This plan is an important input into the annual budget pro- cess. The plan provides information on production rates, manufacturing Inhor requirements, and projected finished goods inventory levels for the next year You make those little boxes of pudding mix on packaging lines in your plant. A packaging line has a number of machines that are linked by comeyors. At the start of the line, the pudding is mixed; it is then placed in small packets. These packets are inserted into the small pudding boxes, which are collected and placed in cases that hold 48 boxes of pudding, Finally, 160 cases are collected and put on a pallet. The pallets are staged in a ship- ping area from which they are sent to four distribution centers Over the years, the technology of the packaging lines has im- proved so that all the different flors can be made in relatively small batches with no setup time to switch between flavors. The plant has 15 of these lines, but currently only 10 are being used, Six employees are required to run each line. The demand for this product fluctuates from mooth to month. In addition, there is a seasonal component, with peak sales before Thanksgiving. Christmas, and Easter each year. To complicate matters, at the end of the first quarter of each year the marketing group runs a promotion in which special deals are made for large purchases. Business is going well, and the com- pany has been experiencing a general increase in sales. The plant sends product to four large distribution ware houses strategically located in the United States. Trucks move product daily. The amounts shipped are based on maintaining target inventory levels at the warehouses. These targets are cal culated based on anticipated weeks of supply at each ware- house. Current targets are set at two weeks of supply. In the past, the company has had a policy of producing very close to what it expects sales to be because of limited capacity for storing finished goods. Production capacity has been adequate to support this policy A sales forecast for next year has been prepared by the mar keting department. The forecast is based on quarterly sales quotas, which are used to set up an incentive program for the salespeople. Sales are mainly to the large U.S. retail grocers. 7. It expected demand during the next four quarters is 150, 125, 100, and 75 thousand units, and each worker can produce 1,000 units per quarter, how many workers should be used if a level strategy is being employed? 8. Given the data from question 7. how many workers would be needed for a chase strategy? 9. In a service setting, what general operations-related variable is not available compared to a production setting? 10. The practice of allocating capacity and manipulating demand to make it more predictable 1. Term used to refer to the process a tim uses to hal ance supply and demand 2. When doing aggregate planning, these are the tree general operations related variables that can be adjusted 3. A strategy where the production rate is set to match expected demand 4. When crvertime is used to meet demand and avoid the costs associated with hiring and firing. 5. A strategy that uses inventory and backorders as part of the strategy to meet demand 6. Sometimes a firm may choose to have all or part of the work done by an outside vendor. This is the term used for the approach Technical and Economic Information 1. The plant runs 5 days each week, and currently is ning 10 lines with no overtime Each line reunites sis people to run. For planning purposes, the lines are run for 7.5 hours cach normal shift. Employees, though, an paid for eight hours' work. It is possible to run up 10100 hours of overtime each day, but it must be scheduled for a week at a time, and all the lines must run overtime when it is scheduled. Workers are paid $20 hours ing a regular shift and 530,00/hour on overtime. The standard production rate for each line is 450 cases four 2. The marketing forecast for demand is as follows: QL 2.000; 02-2,200; Q32.500), 04 -2.650; and QI (next year)-2,200. These numbers are in 1.000-case units. Each number represents a 13 week forecast 3. Management has instructed manufacturing to maintain a two-week safety stock supply of pudding inventory in the warehouses. The two-week supply should be based on future expected sales. The following are end ing inventory target levels to comply with the salty stock requirement for each quarter: Q1-338 02- 385:03 408:04-338. 3u34.atruct1 pax () 6174111 6 SL 001 SZI OS 8 CILL SS 9 Kms ('S Sou Pom - 300M US S'E Kanal on au pouz Sujud suoquado pur sales 'n weg oppeid 01 Samsuy 30.01923. shipped at 40 per case 4. Inventory carrying cost is estimated by accounting to be $1.00 per case per year. This means that if a case of pudding is held in inventory for an entire year, the cost to just carry that case in inventory is $1.00. If a case is carried for only one week, the cost is $1.00/52, or The cost is proportional to the time carried in inventory. There are 200,000 cases in inventory at the beginning of Q1 (this is 200 cases in the 1,000-case units that the forecast is given in). 5. If a stock out occurs, the item is backordered and a later date. The cost when a backorder occurs is $2.40 per case due to the loss of goodwill and the high cost of emergency shipping, 6. The human resource group estimates that it costs $5,000 to hire and train a new production employee. It costs $3,000 to lay off a production worker. 7. Make the following assumptions in your cost calculations: Inventory costs are based on on inventory in excess of the safety stock requirement. Backorder costs are incurred on the negative devia tion from the planned safety stock requirement, even though planned inventory may be positive. Overtime must be used over an entire quarter and should be based on hours per day over that time. Questions 1. Prepare an aggregate plan for the coming year, assuming that the sales forecast is perfect. Use the spreadsheet "Bradford Manufacturing." In the spreadsheet, an area has been designated for your aggregate plan solution. Supply the number of packaging lines to run and the number of overtime hours for each quarter. You will need to set up the cost calculations in the spreadsheet. You may want to try using the Excel Solver to find a lowcost solution. Remember that your final solution needs an integer number of lines and an integer num- her of overtime hours for each quarter. (Solutions that require 8.9134 lines and 1.256 hours of overtime are not feasible. It is important that your spreadsheet calculations are set up so that any values in the number of lines and overtime hours rows evaluates correctly. Your spread- sheet will be evaluated based on this, 2. Find a solution to the problem that goes beyond just minimizing cost. Prepare a short write-up that de- scribes the process you went through to find your solu- tion and that justifies why you think it is a good solution PRACTICE EXAM The pudding is shipped to the grocers from the non Your immediate task is to prepare an aglino the coming year. The technical and economie foto beronvertime hours for cach quarter (Solutions Tel.9154 Ines and 1756 hours of overtime are warehouses based on orders taken by the salespeople must be considered in this plan are shown next Forecast Demand by Quarter (1,000 Casei 3.000 2.500 the high cost of emergency shopping 6. The human resource group estimates $5,000 to hire and train a new product costs $3,000 to lay off a production worden + Make the following assumptions in your com Inventory costs are based on investory in excess the safety stock requirement . Backorder costs are incurred on the negative devis tion from the planned safely stock recuiremini even though planned inventory may be positive, Overtime must be used over an entire quarter ind should be based on hours per day over the time It is important that your spreadsheet calculations 30 stup so that any values in the number of lines and overtime houtstows evaluates correctly. Your spread sheet will be evaluated based on this 2. Find a solution to the problem that goes beyond just minimizing cost, Prepare a short write up that de- scribes the process you went through to find your solu tion and that justifies why you think it is a good solution 2.000 1.500 1.00 500 PRACTICE EXAM 0 Ist (1-13) (27-39) 4th (40-52) Next Year The Situation You are the operations manager for a manufacturing plant that produces pudding food products. One of your important responsibilities is to prepare an aggregate plan for the plant This plan is an important input into the annual budget pro- cess. The plan provides information on production rates, manufacturing Inhor requirements, and projected finished goods inventory levels for the next year You make those little boxes of pudding mix on packaging lines in your plant. A packaging line has a number of machines that are linked by comeyors. At the start of the line, the pudding is mixed; it is then placed in small packets. These packets are inserted into the small pudding boxes, which are collected and placed in cases that hold 48 boxes of pudding, Finally, 160 cases are collected and put on a pallet. The pallets are staged in a ship- ping area from which they are sent to four distribution centers Over the years, the technology of the packaging lines has im- proved so that all the different flors can be made in relatively small batches with no setup time to switch between flavors. The plant has 15 of these lines, but currently only 10 are being used, Six employees are required to run each line. The demand for this product fluctuates from mooth to month. In addition, there is a seasonal component, with peak sales before Thanksgiving. Christmas, and Easter each year. To complicate matters, at the end of the first quarter of each year the marketing group runs a promotion in which special deals are made for large purchases. Business is going well, and the com- pany has been experiencing a general increase in sales. The plant sends product to four large distribution ware houses strategically located in the United States. Trucks move product daily. The amounts shipped are based on maintaining target inventory levels at the warehouses. These targets are cal culated based on anticipated weeks of supply at each ware- house. Current targets are set at two weeks of supply. In the past, the company has had a policy of producing very close to what it expects sales to be because of limited capacity for storing finished goods. Production capacity has been adequate to support this policy A sales forecast for next year has been prepared by the mar keting department. The forecast is based on quarterly sales quotas, which are used to set up an incentive program for the salespeople. Sales are mainly to the large U.S. retail grocers. 7. It expected demand during the next four quarters is 150, 125, 100, and 75 thousand units, and each worker can produce 1,000 units per quarter, how many workers should be used if a level strategy is being employed? 8. Given the data from question 7. how many workers would be needed for a chase strategy? 9. In a service setting, what general operations-related variable is not available compared to a production setting? 10. The practice of allocating capacity and manipulating demand to make it more predictable 1. Term used to refer to the process a tim uses to hal ance supply and demand 2. When doing aggregate planning, these are the tree general operations related variables that can be adjusted 3. A strategy where the production rate is set to match expected demand 4. When crvertime is used to meet demand and avoid the costs associated with hiring and firing. 5. A strategy that uses inventory and backorders as part of the strategy to meet demand 6. Sometimes a firm may choose to have all or part of the work done by an outside vendor. This is the term used for the approach Technical and Economic Information 1. The plant runs 5 days each week, and currently is ning 10 lines with no overtime Each line reunites sis people to run. For planning purposes, the lines are run for 7.5 hours cach normal shift. Employees, though, an paid for eight hours' work. It is possible to run up 10100 hours of overtime each day, but it must be scheduled for a week at a time, and all the lines must run overtime when it is scheduled. Workers are paid $20 hours ing a regular shift and 530,00/hour on overtime. The standard production rate for each line is 450 cases four 2. The marketing forecast for demand is as follows: QL 2.000; 02-2,200; Q32.500), 04 -2.650; and QI (next year)-2,200. These numbers are in 1.000-case units. Each number represents a 13 week forecast 3. Management has instructed manufacturing to maintain a two-week safety stock supply of pudding inventory in the warehouses. The two-week supply should be based on future expected sales. The following are end ing inventory target levels to comply with the salty stock requirement for each quarter: Q1-338 02- 385:03 408:04-338. 3u34.atruct1 pax () 6174111 6 SL 001 SZI OS 8 CILL SS 9 Kms ('S Sou Pom - 300M US S'E Kanal on au pouz Sujud suoquado pur sales 'n weg oppeid 01 Samsuy

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock