Question: Hw #5 Answer the following problems * Show ALL WORKI 3(A-D),4,19,20 31 cation for these Unit Cost Uni Cost 20 4. Por, 5100, E130 Find

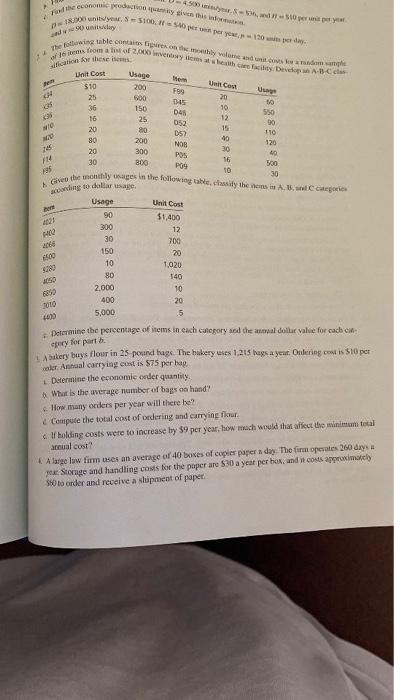

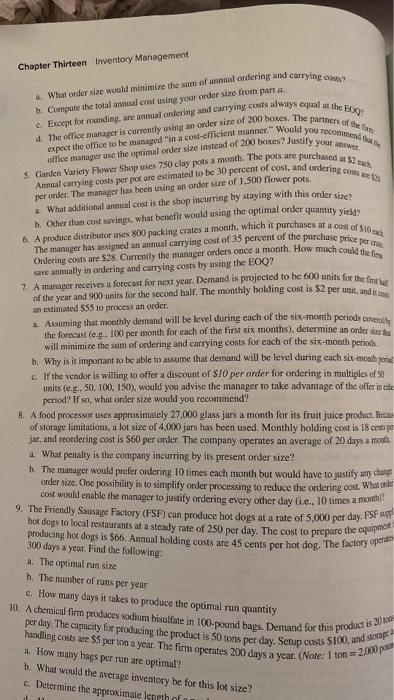

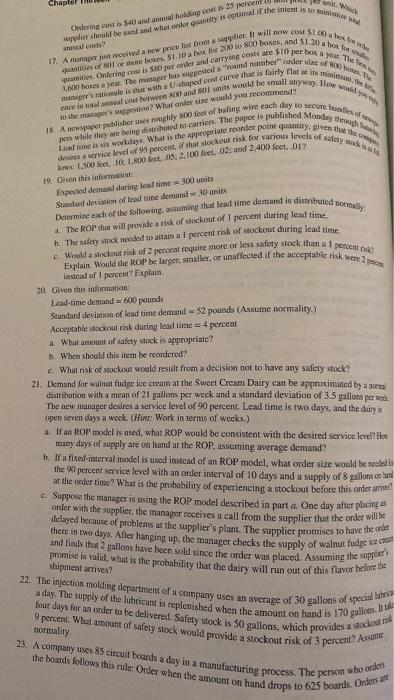

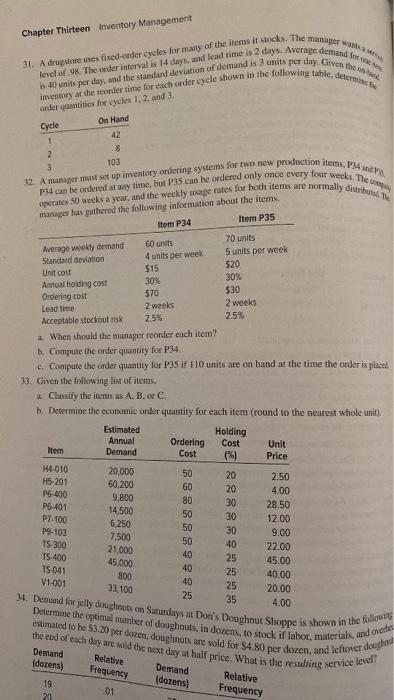

Hw #5 Answer the following problems * Show ALL WORKI 3(A-D),4,19,20 31 cation for these Unit Cost Uni Cost 20 4. Por, 5100, E130 Find Moden this Story The intable context menu and me from Ny Time Devices Usage $10 200 25 600 DUS 36 150 10 048 16 25 12 052 90 20 80 D57 110 40 200 NOS 120 20 300 30 40 800 500 10 30 A Gre the monthly ages in the following the classify the ABC to dollara Usage 90 300 12 30 700 150 20 10 1,020 80 140 2.000 10 400 20 5 15 IN 30 POS POS cardie Unit Cost $1,400 4121 500 280 050 6850 5.000 gery for part Determine the percentage of them in each category and the atmoal dollar value for cada Abakery buys flour in 25 pound bags. The bakery uses 1,215 bags a year. Ordering cost is $10 per aler Annual carrying cost is $75 per hap Determine the economic order quantity What is the average number of bags on hand How many orders per year will there be? Compute the total cost of ordering and carrying flour . holding costs were to increase by 39 per year, www.ch would that affect the minimum total annual cost? A large low firm sex an average of 40 boxes of copler paper day. The firm operates 260 days O Storge and handling costs for the paper are $30 a yeat per box, and it costs approximately S to order and receive a shipment of paper. Chapter Thirteen Inventory Management What order sice would minimize the sum of animal ordering and carrying CONS? h. Compute the total annual cost using your order size from part a. c. Except for rounding an annual ordering and carrying costs always equal at the d. The office manager is currently using an order size of 200 boxes. The partners of them expect the office to be managed in a cost-efficient manner. Would you recommend office manager use the optimal order size instead of 200 boxes? Justify your we 5 Garden Variety Flower Shop uses 750 clay pots a month. The pots are purchased Sach Annual carrying costs per pocare estimated to be 30 percent of cost and ordering per ordet. The manager has been using an order site of 1,500 flower pots . What additional annual cost is the shop incurring by staying with this order site 1. Other than cost savings, what benefit would using the optimal order quantity yield 6. A produce distributor uses 800 packing crates a month, which it purchases at a cost of SV The manager has assigned an annual carrying cost of 35 percent of the purchase price percht Ordering costs are $28. Currently the manager orders once a month. How much could them save annually in ordering and carrying costs by using the EOQ? 7. A manager seceives a forecast for next year. Demand is projected to be 660 units for the fina by of the year and 900 units for the second half. The monthly holding cost is $2 per unit, and it an estimated 555 to process an order a Assuming that monthly demand will be level during each of the six-month periods couette the forecast (e.g. 100 per month for each of the first six months), determine an order via will minimize the sum of ordering and carrying costs for each of the six-month period . Why is it important to be able to assume that demand will be level during each six-month pering c. If the vendor is willing to offer a discount of S70 per order for ordering in multiples of 30 units (e.g. 50, 100, 150), would you advise the manager to take advantage of the offer in eitt period? If so, what order size would you recommend? 8. A food processor uses approximately 27.000 glass jars a month for its fruit juice product. Bem of storage limitations, a lot size of 4,000 jars has been used. Monthly holding cost is 18 centipo jar, and reordering cost is S60 per order. The company operates an average of 20 days amb 4. What penalty is the company incurring by its present order size? h. The manager would prefer ordering 10 times each month but would have to justify any change order size. One posibility is to simplify order processing to reduce the ordering cost. What and cost would enable the manager to justify ordering every other day (i... 10 times a month 9. The Friendly Sausage Factory (FSF) can produce hot dogs at a rate of 5,000 per day. FSF hot dogs to local restaurants at a steady rate of 250 per day. The cost to prepare the equipe producing hot dogs is $66. Annual holding costs are 45 cents per hot dog. The factory operate 300 days a year. Find the following: 2. The optimal run size b. The number of runs per year c. How many days it takes to produce the optimal run quantity 10. A chemical firm produces sodium bisulfate in 100-pound bags. Demand for this product is 20 per day. The capacity for producing the product is 50 tons per day. Setup costs S100, and storage handling costs are SS per ton a year. The firm operates 200 days a year. (Note: 1 ton a. How many bags per run are optimal b. What would the average inventory be for this lot size? c. Determine the approximale length of 2.000 por Chapter Wh Ordering cost is $40 annual holding costs 25 percent sed and whaler the intent is to move 17 Amager da pride out fra der I will now costi Malom La for NSO bancs, and 1.20 abon O homes a year. The manager tres de around unter ander size of ma's le is that with a hand cost curve that is fairly flat at its tim. One ties. Ondering cast is 500 per order and carrying coste0 per boxy ence in total betwee and Tits would be small anyway. How IR Apper publisher Wy food baling wire each day to secure bundeso desires and level of 95 percent of that stockou ask for various levels of sy w Lad time is six world. Was the appropriate reorder point quantity, given the pues while they are being distributed to carriers. The paper is published Monday the to the manager in What artier size would you recommend 1.300 feet 101.800 foct. 05. 2.100 feet 02, and 2.400 feet..017 19. Gre this imatic Expected demand during lead time 300 units Standard deviation of lead time demand 30 units Determine each of the following. aming that lead time demand is distributed tomaty The ROP tu will provide a risk of stockout of percent during lead time h. The safety stock needed to attain a I percent risk of stockout during lead time Explain. Would the ROP be larger smaller, or unaffected if the acceptable risk were 2 cm Wild a scout risk of 2 percent ne more or less safety stock thasal pero instead of 1 percent? Explain 20. Given this information: Lead-time demand = 600 pounds Standard deviation of lead time demand - 52 pounds (Assume normality) Acceptable stockout risk during lead time = 4 percent a. What amount of safety stock is appropriate When should this item be reordered c. What risk of stockout would result from a decision not to have any safety stock? 21. Demand for walnut fudge ice cream at the Sweet Cream Dairy can be approximated by a metal distribution with a mean of 21 gallons per week and a standard deviation of 3.5 gallons per week. The new manager desires a service level of 90 percent. Lead time is two days, and the dairy opeo seven days a week. (Hint: Work in terms of weeks) If an ROP model is tised, what ROP would be consistent with the desired service level many days of supply are on hand at the ROP assuming average demand? b. If a fixed-interval model is used instead of an ROP model, what order size would be noted the 90 percent service level with an order interval of 10 days and a supply of 8 gallons de la at the order time? What is the probability of experiencing a stockout before this order anised - Suppose the manager is using the ROP model described in part a. One day after placing a order with the supplier, the manager receives a call from the supplier that the order will be deiayed because of problems at the supplier's plant. The supplier promises to have the order there in two days. After hanging up, the manager checks the supply of walnut fudge cast and finds that 2 gallons have been sold since the order was placed. Assuming the superi promise is valid what is the probability that the dairy will run out of this flavor before the shipment arrives? 22. The injection molding department of a company uses an average of 30 gallons of specialista four days for an order to be delivered Safely stock is 50 gallons, which provides a stockout rid a day. The supply of the lubricant is replenished when the amount on hand is 170 gallons 9 percent. What amount of safety stock would provide a stockout risk of 3 percent? Assum normality 23. A company uses 85 circuit boards a day in a manufacturing process. The person who orders the boards follows this rule: Order when the amount on hand drops to 625 boards. Orders at Chapter Thirteen Inventory Management Jl. A drugstore uses Tired-onder cles for many w the items it socks. The anapewa level of.98. The order interval is 14 days, and lead time is 2 days. Average demand for 40 units per day, and the standind deviation of demand is 3 units per day. Given the inventory at the reader time for each order cycle shown in the following table, determine onde quantities for cycles 1, 2 and 3. Cycle On Hand 1 2 8 3 103 Amager mest set up inventory ordering systems for two new production items, P3 P34 can be ordered at any time, but P3S can be ordered only once every four weeks. The operates 50 weeks a year, and the weekly wage rates for both items are normally do the manager las gathered the following information about the items. Item P34 Item P35 70 units 60 units Average weekly demand Standard deviation 4 units per week 5 units per week Unit cost $15 $20 Annual holding cost 30% 30% Ordering cost $70 $30 Lead time 2 weeks 2 weeks Acceptable stockout risk 2.5% 2.5% When should the manager reorder each item? Compute the order quantity for P34 4. Compute the order quantity for P35 ir 110 units are on hand at the time the order is placed 13. Given the following list of items. 2 Classify the items as A. B. or C. h. Determine the economic onder quantity for each item (round to the nearest whole unit) Estimated Holding Annual Ordering Cost Unit Item Demand Cost (%) Price H4.010 20,000 50 20 2.50 H5-201 60,200 60 20 4.00 P6-400 9,800 80 30 28.50 P5-401 14,500 50 30 P7.100 12.00 6.250 50 30 P9-103 9.00 50 TS-300 40 22.00 TS 400 25 45.00 TS-041 40 25 40.00 800 V1-001 40 25 20.00 25 35 4.00 31. Demand for jelly doughts on Saturdays at Don's Doughnut Shoppe is shown in the following the end of each day are sold the next day at half price. What is the resulting service level estimated to be $3.00 per dowen, doughnuts are sold for $4.80 per dozen, and leftover dough Determine the optimal number of doughnuts, in dozens, to stock if labor, materials, and certis Demand m www8888 7,500 21,000 45.000 33, 100 (dozens) Relative Frequency 01 Demand dozens) 19 20 Relative Frequency Hw #5 Answer the following problems * Show ALL WORKI 3(A-D),4,19,20 31 cation for these Unit Cost Uni Cost 20 4. Por, 5100, E130 Find Moden this Story The intable context menu and me from Ny Time Devices Usage $10 200 25 600 DUS 36 150 10 048 16 25 12 052 90 20 80 D57 110 40 200 NOS 120 20 300 30 40 800 500 10 30 A Gre the monthly ages in the following the classify the ABC to dollara Usage 90 300 12 30 700 150 20 10 1,020 80 140 2.000 10 400 20 5 15 IN 30 POS POS cardie Unit Cost $1,400 4121 500 280 050 6850 5.000 gery for part Determine the percentage of them in each category and the atmoal dollar value for cada Abakery buys flour in 25 pound bags. The bakery uses 1,215 bags a year. Ordering cost is $10 per aler Annual carrying cost is $75 per hap Determine the economic order quantity What is the average number of bags on hand How many orders per year will there be? Compute the total cost of ordering and carrying flour . holding costs were to increase by 39 per year, www.ch would that affect the minimum total annual cost? A large low firm sex an average of 40 boxes of copler paper day. The firm operates 260 days O Storge and handling costs for the paper are $30 a yeat per box, and it costs approximately S to order and receive a shipment of paper. Chapter Thirteen Inventory Management What order sice would minimize the sum of animal ordering and carrying CONS? h. Compute the total annual cost using your order size from part a. c. Except for rounding an annual ordering and carrying costs always equal at the d. The office manager is currently using an order size of 200 boxes. The partners of them expect the office to be managed in a cost-efficient manner. Would you recommend office manager use the optimal order size instead of 200 boxes? Justify your we 5 Garden Variety Flower Shop uses 750 clay pots a month. The pots are purchased Sach Annual carrying costs per pocare estimated to be 30 percent of cost and ordering per ordet. The manager has been using an order site of 1,500 flower pots . What additional annual cost is the shop incurring by staying with this order site 1. Other than cost savings, what benefit would using the optimal order quantity yield 6. A produce distributor uses 800 packing crates a month, which it purchases at a cost of SV The manager has assigned an annual carrying cost of 35 percent of the purchase price percht Ordering costs are $28. Currently the manager orders once a month. How much could them save annually in ordering and carrying costs by using the EOQ? 7. A manager seceives a forecast for next year. Demand is projected to be 660 units for the fina by of the year and 900 units for the second half. The monthly holding cost is $2 per unit, and it an estimated 555 to process an order a Assuming that monthly demand will be level during each of the six-month periods couette the forecast (e.g. 100 per month for each of the first six months), determine an order via will minimize the sum of ordering and carrying costs for each of the six-month period . Why is it important to be able to assume that demand will be level during each six-month pering c. If the vendor is willing to offer a discount of S70 per order for ordering in multiples of 30 units (e.g. 50, 100, 150), would you advise the manager to take advantage of the offer in eitt period? If so, what order size would you recommend? 8. A food processor uses approximately 27.000 glass jars a month for its fruit juice product. Bem of storage limitations, a lot size of 4,000 jars has been used. Monthly holding cost is 18 centipo jar, and reordering cost is S60 per order. The company operates an average of 20 days amb 4. What penalty is the company incurring by its present order size? h. The manager would prefer ordering 10 times each month but would have to justify any change order size. One posibility is to simplify order processing to reduce the ordering cost. What and cost would enable the manager to justify ordering every other day (i... 10 times a month 9. The Friendly Sausage Factory (FSF) can produce hot dogs at a rate of 5,000 per day. FSF hot dogs to local restaurants at a steady rate of 250 per day. The cost to prepare the equipe producing hot dogs is $66. Annual holding costs are 45 cents per hot dog. The factory operate 300 days a year. Find the following: 2. The optimal run size b. The number of runs per year c. How many days it takes to produce the optimal run quantity 10. A chemical firm produces sodium bisulfate in 100-pound bags. Demand for this product is 20 per day. The capacity for producing the product is 50 tons per day. Setup costs S100, and storage handling costs are SS per ton a year. The firm operates 200 days a year. (Note: 1 ton a. How many bags per run are optimal b. What would the average inventory be for this lot size? c. Determine the approximale length of 2.000 por Chapter Wh Ordering cost is $40 annual holding costs 25 percent sed and whaler the intent is to move 17 Amager da pride out fra der I will now costi Malom La for NSO bancs, and 1.20 abon O homes a year. The manager tres de around unter ander size of ma's le is that with a hand cost curve that is fairly flat at its tim. One ties. Ondering cast is 500 per order and carrying coste0 per boxy ence in total betwee and Tits would be small anyway. How IR Apper publisher Wy food baling wire each day to secure bundeso desires and level of 95 percent of that stockou ask for various levels of sy w Lad time is six world. Was the appropriate reorder point quantity, given the pues while they are being distributed to carriers. The paper is published Monday the to the manager in What artier size would you recommend 1.300 feet 101.800 foct. 05. 2.100 feet 02, and 2.400 feet..017 19. Gre this imatic Expected demand during lead time 300 units Standard deviation of lead time demand 30 units Determine each of the following. aming that lead time demand is distributed tomaty The ROP tu will provide a risk of stockout of percent during lead time h. The safety stock needed to attain a I percent risk of stockout during lead time Explain. Would the ROP be larger smaller, or unaffected if the acceptable risk were 2 cm Wild a scout risk of 2 percent ne more or less safety stock thasal pero instead of 1 percent? Explain 20. Given this information: Lead-time demand = 600 pounds Standard deviation of lead time demand - 52 pounds (Assume normality) Acceptable stockout risk during lead time = 4 percent a. What amount of safety stock is appropriate When should this item be reordered c. What risk of stockout would result from a decision not to have any safety stock? 21. Demand for walnut fudge ice cream at the Sweet Cream Dairy can be approximated by a metal distribution with a mean of 21 gallons per week and a standard deviation of 3.5 gallons per week. The new manager desires a service level of 90 percent. Lead time is two days, and the dairy opeo seven days a week. (Hint: Work in terms of weeks) If an ROP model is tised, what ROP would be consistent with the desired service level many days of supply are on hand at the ROP assuming average demand? b. If a fixed-interval model is used instead of an ROP model, what order size would be noted the 90 percent service level with an order interval of 10 days and a supply of 8 gallons de la at the order time? What is the probability of experiencing a stockout before this order anised - Suppose the manager is using the ROP model described in part a. One day after placing a order with the supplier, the manager receives a call from the supplier that the order will be deiayed because of problems at the supplier's plant. The supplier promises to have the order there in two days. After hanging up, the manager checks the supply of walnut fudge cast and finds that 2 gallons have been sold since the order was placed. Assuming the superi promise is valid what is the probability that the dairy will run out of this flavor before the shipment arrives? 22. The injection molding department of a company uses an average of 30 gallons of specialista four days for an order to be delivered Safely stock is 50 gallons, which provides a stockout rid a day. The supply of the lubricant is replenished when the amount on hand is 170 gallons 9 percent. What amount of safety stock would provide a stockout risk of 3 percent? Assum normality 23. A company uses 85 circuit boards a day in a manufacturing process. The person who orders the boards follows this rule: Order when the amount on hand drops to 625 boards. Orders at Chapter Thirteen Inventory Management Jl. A drugstore uses Tired-onder cles for many w the items it socks. The anapewa level of.98. The order interval is 14 days, and lead time is 2 days. Average demand for 40 units per day, and the standind deviation of demand is 3 units per day. Given the inventory at the reader time for each order cycle shown in the following table, determine onde quantities for cycles 1, 2 and 3. Cycle On Hand 1 2 8 3 103 Amager mest set up inventory ordering systems for two new production items, P3 P34 can be ordered at any time, but P3S can be ordered only once every four weeks. The operates 50 weeks a year, and the weekly wage rates for both items are normally do the manager las gathered the following information about the items. Item P34 Item P35 70 units 60 units Average weekly demand Standard deviation 4 units per week 5 units per week Unit cost $15 $20 Annual holding cost 30% 30% Ordering cost $70 $30 Lead time 2 weeks 2 weeks Acceptable stockout risk 2.5% 2.5% When should the manager reorder each item? Compute the order quantity for P34 4. Compute the order quantity for P35 ir 110 units are on hand at the time the order is placed 13. Given the following list of items. 2 Classify the items as A. B. or C. h. Determine the economic onder quantity for each item (round to the nearest whole unit) Estimated Holding Annual Ordering Cost Unit Item Demand Cost (%) Price H4.010 20,000 50 20 2.50 H5-201 60,200 60 20 4.00 P6-400 9,800 80 30 28.50 P5-401 14,500 50 30 P7.100 12.00 6.250 50 30 P9-103 9.00 50 TS-300 40 22.00 TS 400 25 45.00 TS-041 40 25 40.00 800 V1-001 40 25 20.00 25 35 4.00 31. Demand for jelly doughts on Saturdays at Don's Doughnut Shoppe is shown in the following the end of each day are sold the next day at half price. What is the resulting service level estimated to be $3.00 per dowen, doughnuts are sold for $4.80 per dozen, and leftover dough Determine the optimal number of doughnuts, in dozens, to stock if labor, materials, and certis Demand m www8888 7,500 21,000 45.000 33, 100 (dozens) Relative Frequency 01 Demand dozens) 19 20 Relative Frequency