Question: I am needing help completing the attached chart. I have the complete question here: - ABC Hardware store is open for business 350 days a

I am needing help completing the attached chart. I have the complete question here:

- ABC Hardware store is open for business 350 days a year. Annual demand for a power cutter at this store is 700 units. Replenishment cost is $15 per order and annual inventory holding cost is 10% of the inventory value. ABC pays $20 for each power cutter. What is the economic order quantity for this cutter, and what is the reorder point if the lead time is 5 days and ABC policy is to keep a safety stock of 10 units?

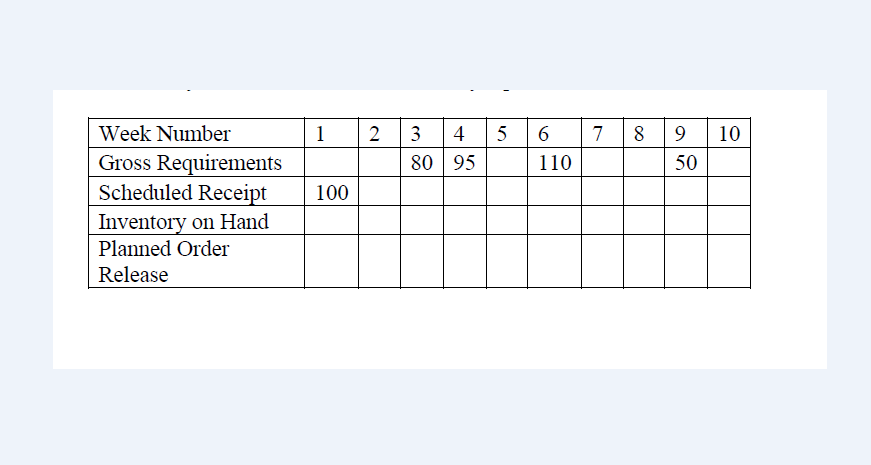

2- The following time-phasing chart is available for a single item within a MRP system. Complete this chart by estimating inventory on hand and planned order release values. Lead time is 2 weeks and order policy is 100 units, which means this part can be ordered only in 100-unit batches. Inventory replenishment is JIT, lead times are negligible.

\fAssignment 2.2 1) ABC Hardware store is open for business 350 days a year. Annual demand for a power cutter at this store is 700 units. Replenishment cost is $15 per order and annual inventory holding cost is 10% of the inventory value. ABC pays $20 for each power cutter. What is the economic order quantity for this cutter, and what is the reorder point if the lead time is 5 days and ABC policy is to keep a safety stock of 10 units? The first step into solving this equation is to calculate what the annual holding cost is per unit. If ABC sells 700 units a year, plus a qty of 10 for safety stock, that would mean that the inventory value is $14200 a year, for that product. To calculate the holding cost annually, it would be 10 percent of $14200 (.10X$14200). This would give us an annual holding cost is $1420. To get this to per month, we would divide that by 12 (months) which would give us the inventory costs of $118. If we take 700 units and divide that by 12 (months), since 700 units are sold yearly, we would have 58 units sold monthly. Next, we take the $118 and divide that by 58 units that are sold monthly, and that gives us $2.03 of holding cost per item. Now we can solve for the Economic order quantity. The annual demand of the Power cutters is 700 units, and the holding cost is $2.03 per unit, also there is a $15 replenishment cost to place each order. We multiply the 700 units times the $15 cost per order, that will give us a total of 10,500. We then take that value, multiply that by 2. That gives us a total of 21000. We then divide that value by the holding cost per order, then take the square root of that total. That calculation would give us the Economic order quantity of 102 units per order. This is the number of pieces that this business should increase to inventory, per order, to reduce the total costs of inventory. In order to find the reorder point of this product, that would be the lead time demand plus the safety stock, and that would give us the reorder point. To find the lead time demand, we need to divide the order quantity of 102 units by the annual demand (700 units) and then multiplying that answer by the days the business is open in a year. The lead time demand would be 51 units. The reorder point would be 51 units + the 10 units in safety stock. The reorder point would be 61 units