Question: I found this problem online but I couldn't understand the problem. I would appreciate it if someone could help me with this question. I hope

I found this problem online but I couldn't understand the problem. I would appreciate it if someone could help me with this question. I hope you can explain how the answer was derived instead of the answer so I can have a better understanding of the problem.

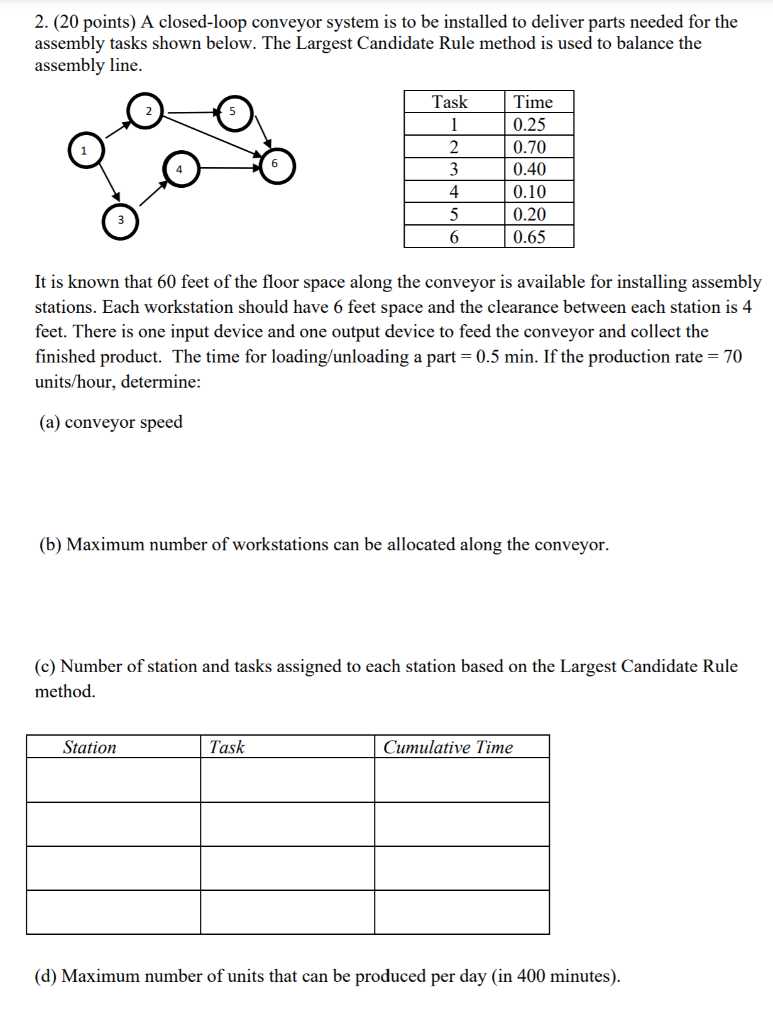

2. (20 points) A closed-loop conveyor system is to be installed to deliver parts needed for the assembly tasks shown below. The Largest Candidate Rule method is used to balance the assembly line. Task 1 2 3 4 5 6 Time 0.25 0.70 0.40 0.10 0.20 0.65 It is known that 60 feet of the floor space along the conveyor is available for installing assembly stations. Each workstation should have 6 feet space and the clearance between each station is 4 feet. There is one input device and one output device to feed the conveyor and collect the finished product. The time for loading/unloading a part = 0.5 min. If the production rate = 70 units/hour, determine: (a) conveyor speed (b) Maximum number of workstations can be allocated along the conveyor. (c) Number of station and tasks assigned to each station based on the Largest Candidate Rule method. Station Task Cumulative Time (d) Maximum number of units that can be produced per day (in 400 minutes)Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts