Question: I have a question about the solution that is attached to the following question. I understand the reasoning for writing the partial pressures in terms

I have a question about the solution that is attached to the following question. I understand the reasoning for writing the partial pressures in terms of moles converted, but am not sure of the steps that follow. Are you able to provide a step by step explanation of how an answer of 23 kg's was reached.

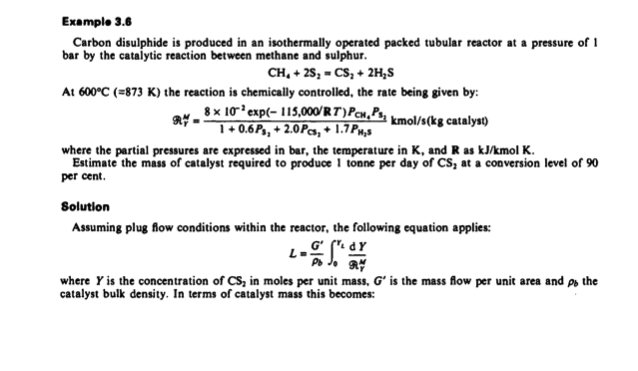

Example 3.6 Carbon disulphide is produced in an isothermally operated packed tubular reactor at a pressure of 1 bar by the catalytic reaction between methane and sulphur. CH, +25, - CS+ 2H, At 600C (=873 K) the reaction is chemically controlled, the rate being given by: 8x 10'exp(- 115,000/RT)Pak, Ps 1 +0.6Ps, +2.0P, + 1.7PM kmol/s(kg catalyst) where the partial pressures are expressed in bar, the temperature in K, and R as kJ/kmol K. Estimate the mass of catalyst required to produce 1 tonne per day of CS, at a conversion level of 90 per cent Solution Assuming plug flow conditions within the reactor, the following equation applies: , L. Gdy Polo Ry where Y is the concentration of cs, in moles per unit mass. G is the mass flow per unit area and Do the catalyst bulk density. In terms of catalyst mass this becomes: 154 CHEMICAL ENGINEERING -o love 1/3 - X 2/3 - 2x where G is now the molar flowrate through the tube. The rate expression is given in terms of partial pressures and this is now rewritten in terms of the number of moles y of methane converted to CS. Consider I mole of gas entering the reactor, then at any cross-section (distance z along the tube from the inlet) the number of moles of reactant and product may be written in terms of as follows: Moles at inlet Moles at position : CH 1/3 S, 2/3 cs, x HAS Total 1.00 1.00 For a pressure of I bar it follows that the partial pressures in the rate expression become: PCHE = (1/3 - x); Ps, = (2/3 - 2x); Pcs, = x and Phys=2% Now if M is the mean molecular weight of the gas at the reactor inlet then x kmol of CS, are produced for every M kg of gas entering the reactor. Hence: 2x Y- and the required catalyst mass is now: W = Gdz More For an expected conversion level of 0.9, the upper limit of the integral will be given by Lb. - 0.9, i.e. -XL by Ke = 0.158. Thus 1 tonne per day (= 1.48 kmol's CS) is produced by using an inlet flow of 6-1.48 x 10*x M kg/s. 0.158 53319dx Hence: 0.158 Jo Substituting the expressions for partial pressures into the rate equation the mass of catalyst required may be determined by direct numerical (or graphical) integration. Thus: W = 23 ks W

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts