Question: I I am curious why I got this question wrong? Demand for a certain subassembly in a toy manufacturing facility is 96 items per eight-hour

I

I am curious why I got this question wrong?

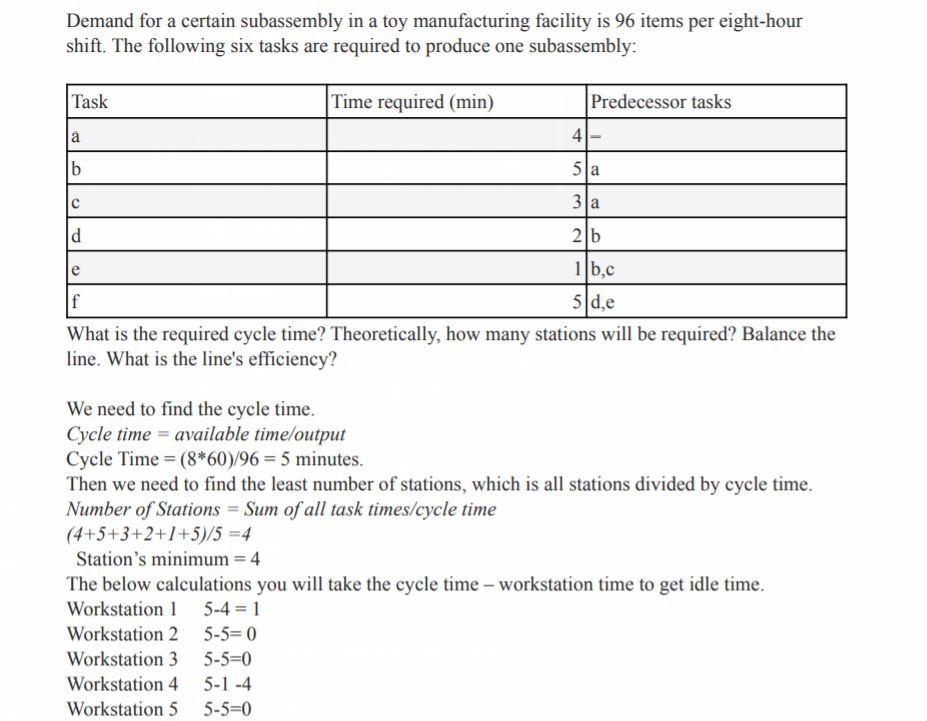

Demand for a certain subassembly in a toy manufacturing facility is 96 items per eight-hour shift. The following six tasks are required to produce one subassembly: Task Time required (min) Predecessor tasks a 4 | 5 a 3 a d 2b 1 b,c f 5 d,e What is the required cycle time? Theoretically, how many stations will be required? Balance the line. What is the line's efficiency? We need to find the cycle time. Cycle time = available time/output Cycle Time = (8*60)/96 = 5 minutes. Then we need to find the least number of stations, which is all stations divided by cycle time. Number of Stations = Sum of all task times/cycle time (4+5+3+2+1+5)/5 = 4 Station's minimum = 4 The below calculations you will take the cycle time - workstation time to get idle time. Workstation 1 5-4 = 1 Workstation 2 5-5=0 Workstation 3 5-5=0 Workstation 4 5-1 -4 Workstation 5 5-5=0 Workstation 4 5-1-4 Workstation 5 5-5=0 Total Idle time is 5 minutes. Cycle time 5 minutes, Minimum Station 4 minutes, and Idle time 5 min. Efficiency = (sum of all tasksumber of work stations X cycle time.) *100 =20/(5*5) *100 Efficiency=80%Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock