Question: i just need an abswer to task 4. Task I: Based on the information in the case study, develop a Project Charter for this project.

i just need an abswer to task 4.

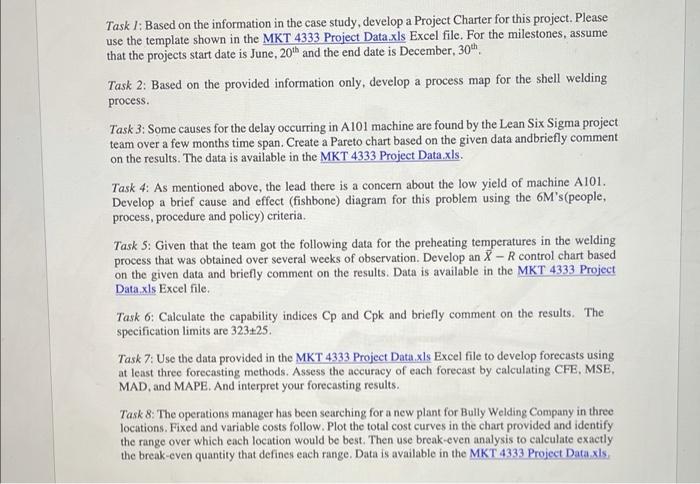

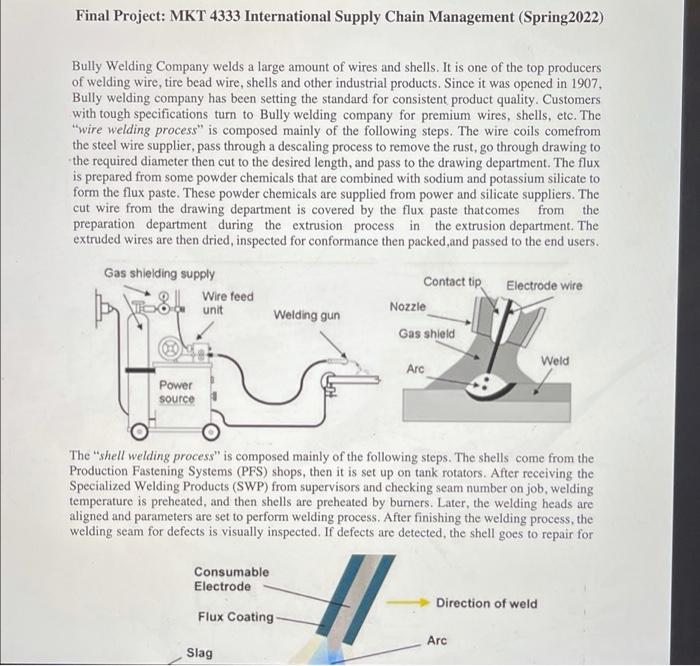

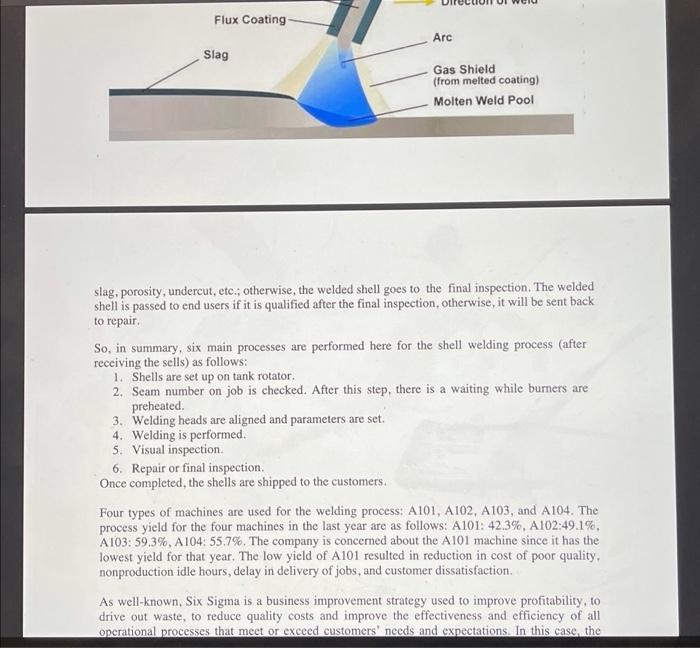

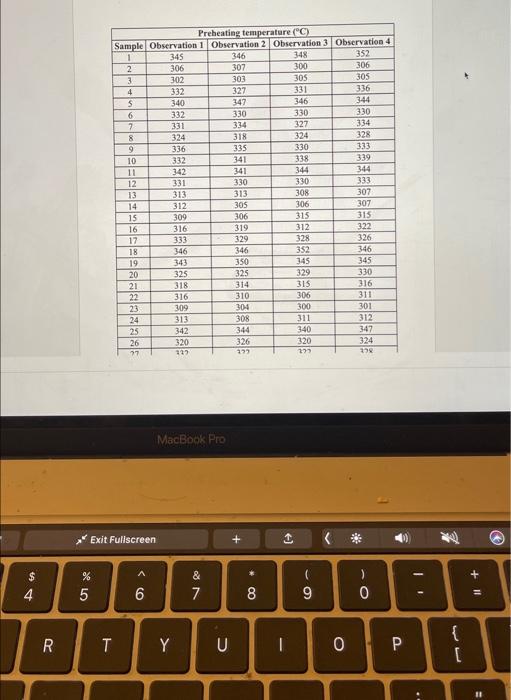

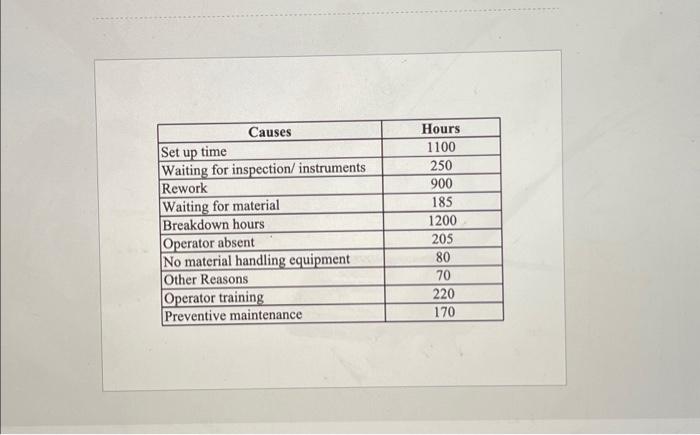

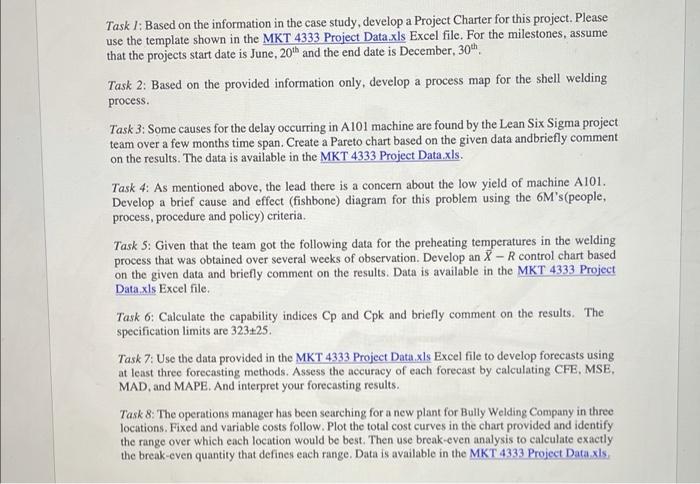

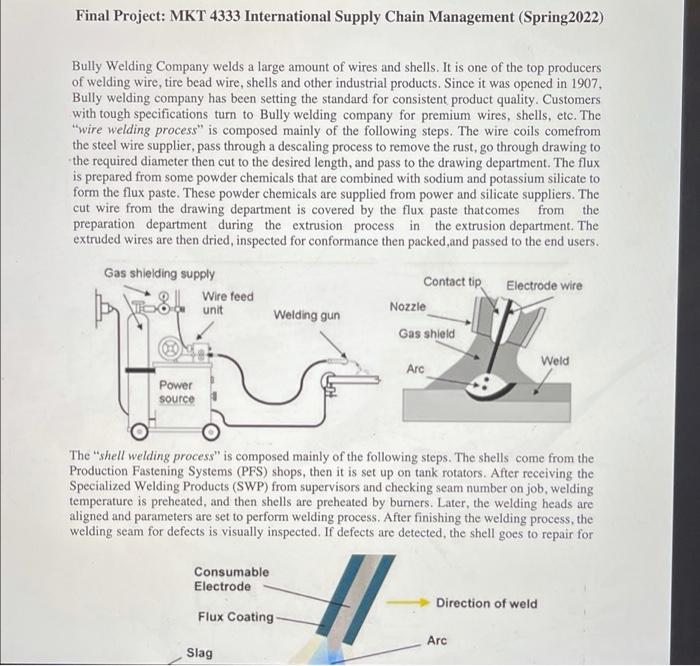

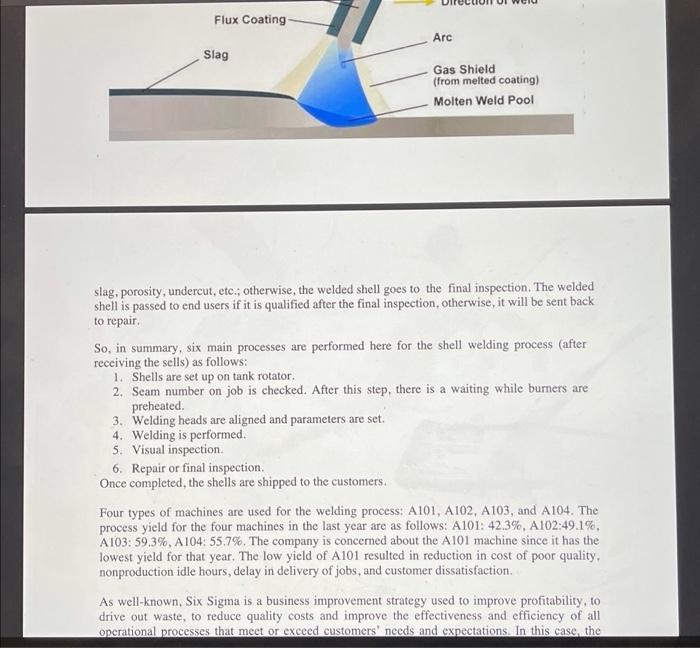

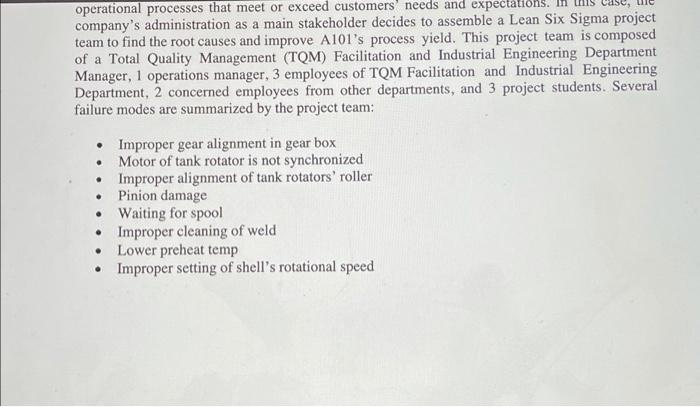

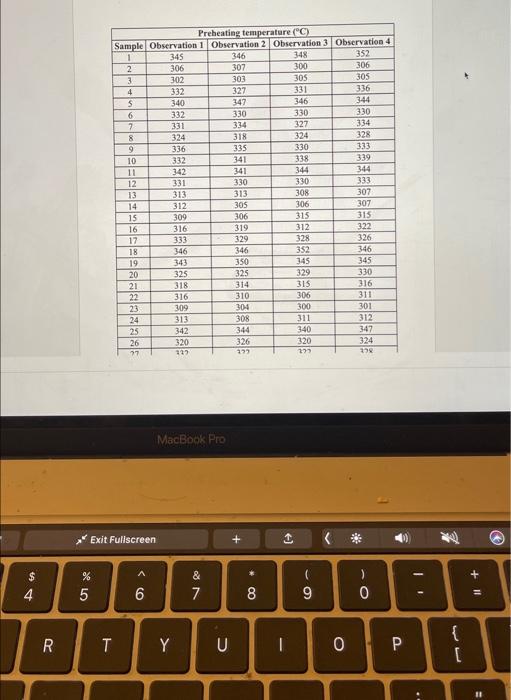

Task I: Based on the information in the case study, develop a Project Charter for this project. Please use the template shown in the MKT 4333 Project Data.xls Excel file. For the milestones, assume that the projects start date is June, 20h and the end date is December, 30 Task 2: Based on the provided information only, develop a process map for the shell welding process. Task 3: Some causes for the delay occurring in A101 machine are found by the Lean Six Sigma project team over a few months time span. Create a Pareto chart based on the given data andbriefly comment on the results. The data is available in the MKT 4333 Project Data.xls. Task 4: As mentioned above, the lead there is a concern about the low yield of machine A101. Develop a brief cause and effect (fishbone) diagram for this problem using the 6M's(people, process, procedure and policy) criteria. Task 5: Given that the team got the following data for the preheating temperatures in the welding process that was obtained over several weeks of observation Develop an X-R control chart based on the given data and briefly comment on the results. Data is available in the MKT 4333 Project Data.xls Excel file Task 6: Calculate the capability indices Cp and Cpk and briefly comment on the results. The specification limits are 323+25. Task 7: Use the data provided in the MKT 4333 Project Data xls Excel file to develop forecasts using at least three forecasting methods. Assess the accuracy of each forecast by calculating CFE, MSE, MAD, and MAPE. And interpret your forecasting results. Task 8: The operations manager has been searching for a new plant for Bully Welding Company in three locations. Fixed and variable costs follow. Plot the total cost curves in the chart provided and identify the range over which each location would be best. Then use break-even analysis to calculate exactly the break-even quantity that defines each range. Data is available in the MKT 4333 Project Data.xls Final Project: MKT 4333 International Supply Chain Management (Spring2022) Bully Welding Company welds a large amount of wires and shells. It is one of the top producers of welding wire, tire bead wire, shells and other industrial products. Since it was opened in 1907, Bully welding company has been setting the standard for consistent product quality. Customers with tough specifications turn to Bully welding company for premium wires, shells, etc. The "wire welding process" is composed mainly of the following steps. The wire coils comefrom the steel wire supplier, pass through a descaling process to remove the rust, go through drawing to the required diameter then cut to the desired length, and pass to the drawing department. The flux is prepared from some powder chemicals that are combined with sodium and potassium silicate to form the flux paste. These powder chemicals are supplied from power and silicate suppliers. The cut wire from the drawing department is covered by the flux paste thatcomes from the preparation department during the extrusion process in the extrusion department. The extruded wires are then dried, inspected for conformance then packed, and passed to the end users. Gas shielding supply Contact tip Electrode wire Wire feed Nozzle Welding gun Gas shield Weld Arc Power source unit The "shell welding process" is composed mainly of the following steps. The shells come from the Production Fastening Systems (PFS) shops, then it is set up on tank rotators. After receiving the Specialized Welding Products (SWP) from supervisors and checking seam number on job, welding temperature is preheated, and then shells are preheated by bumers. Later, the welding heads are aligned and parameters are set to perform welding process. After finishing the welding process, the welding scam for defects is visually inspected. If defects are detected the shell goes to repair for Consumable Electrode // Direction of weld Flux Coating Arc Slag Flux Coating Arc Slag Gas Shield (from melted coating) Molten Weld Pool slag, porosity, undercut, etc.; otherwise, the welded shell goes to the final inspection. The welded shell is passed to end users if it is qualified after the final inspection, otherwise, it will be sent back to repair, So, in summary, six main processes are performed here for the shell welding process (after receiving the sells) as follows: 1. Shells are set up on tank rotator. 2. Seam number on job is checked. After this step, there is a waiting while burners are preheated 3. Welding heads are aligned and parameters are set. 4. Welding is performed. 5. Visual inspection 6. Repair or final inspection Once completed, the shells are shipped to the customers. Four types of machines are used for the welding process: A101, A102, A103, and A104. The process yield for the four machines in the last year are as follows: A101: 42.3%, A102:49.1%, A103: 59.3%, A 104: 55.7%. The company is concerned about the A101 machine since it has the lowest yield for that year. The low yield of A101 resulted in reduction in cost of poor quality, nonproduction idle hours, delay in delivery of jobs, and customer dissatisfaction As well-known, Six Sigma is a business improvement strategy used to improve profitability, to drive out waste, to reduce quality costs and improve the effectiveness and efficiency of all operational processes that meet or exceed customers' needs and expectations. In this case, the operational processes that meet or exceed customers' needs and expectations. In company's administration as a main stakeholder decides to assemble a Lean Six Sigma project team to find the root causes and improve A101's process yield. This project team is composed of a Total Quality Management (TQM) Facilitation and Industrial Engineering Department Manager, 1 operations manager, 3 employees of TQM Facilitation and Industrial Engineering Department, 2 concerned employees from other departments, and 3 project students. Several failure modes are summarized by the project team: Improper gear alignment in gear box Motor of tank rotator is not synchronized Improper alignment of tank rotators' roller Pinion damage Waiting for spool Improper cleaning of weld Lower preheat temp Improper setting of shell's rotational speed . . 335 342 Preheating temperature (C) Sample Observation 1 Observation 2 Observation 3 Observation 4 1 345 346 348 352 2 306 307 300 306 3 302 303 305 305 4 332 327 331 336 S 340 347 346 344 6 332 330 330 330 7 331 334 327 334 8 324 318 324 328 9 336 330 333 10 332 341 338 339 11 341 344 344 12 331 330 330 333 13 313 313 308 307 14 312 305 306 307 15 309 306 315 315 16 316 319 312 322 17 333 329 328 326 18 346 346 352 346 19 343 350 345 345 20 325 325 329 330 21 318 314 315 316 22 316 310 306 311 23 309 304 301 24 313 308 311 312 25 342 344 340 347 26 320 326 320 324 77 212 139 279 300 MacBook Pro Exit Fullscreen + + 1 e A * $ 4 % 5 & 7 ( 9 + II 6 8 O R T Y U OP P { [ : Causes Set up time Waiting for inspection/instruments Rework Waiting for material Breakdown hours Operator absent No material handling equipment Other Reasons Operator training Preventive maintenance Hours 1100 250 900 185 1200 205 80 70 220 170

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock