Question: i need a neat detail answer pls.... A distillation column is designed to separate a mixture of multicomponent as shown in Table 2. The feed

i need a neat detail answer pls....

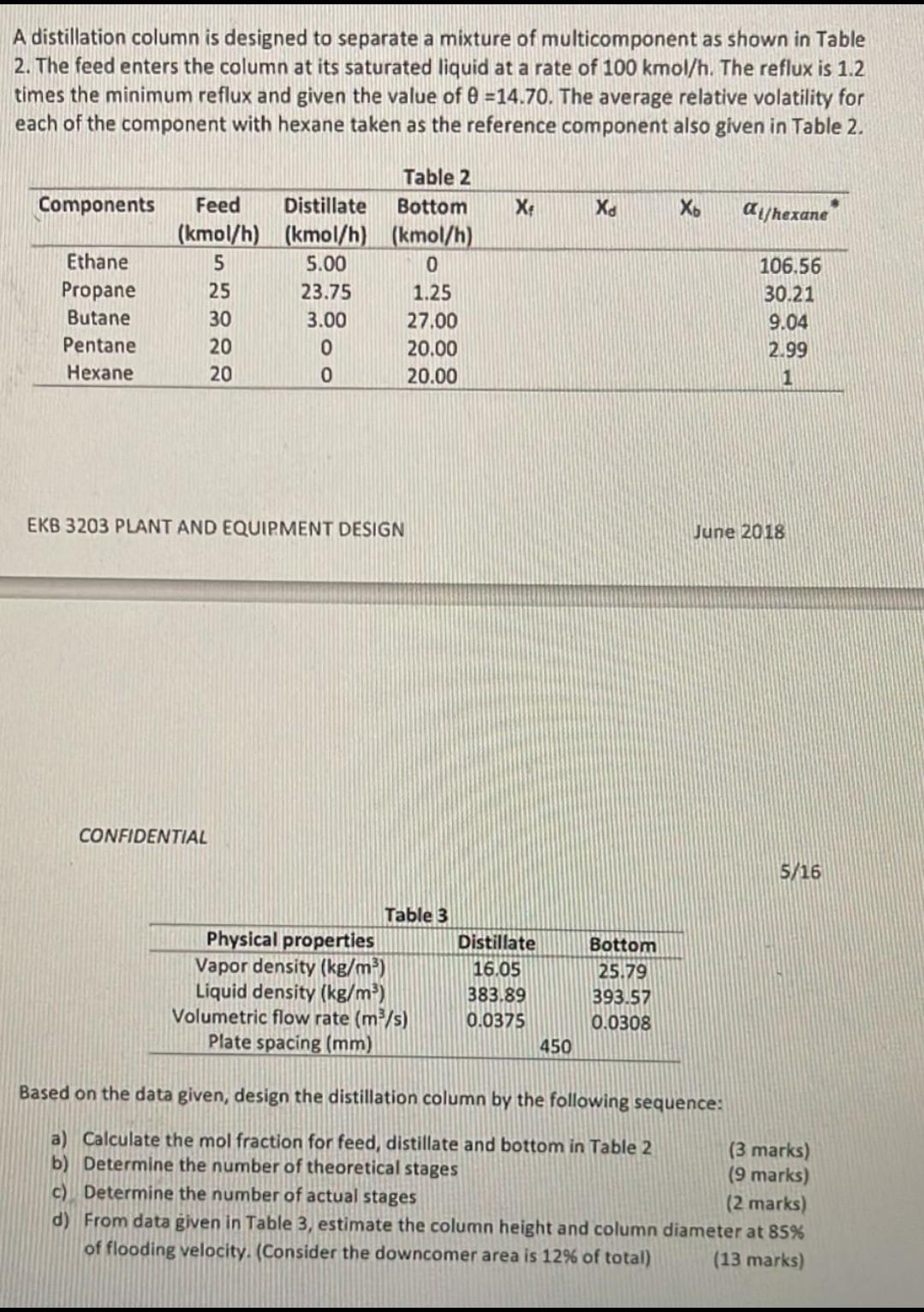

A distillation column is designed to separate a mixture of multicomponent as shown in Table 2. The feed enters the column at its saturated liquid at a rate of 100 kmol/h. The reflux is 1.2 times the minimum reflux and given the value of 0 =14.70. The average relative volatility for each of the component with hexane taken as the reference component also given in Table 2. Components X Xo Xb Qt/hexane Ethane Propane Butane Pentane Hexane Feed Distillate (kmol/h) (kmol/h) 5 5.00 25 23.75 30 3.00 20 0 20 0 Table 2 Bottom (kmol/h) 0 1.25 27.00 20.00 20.00 106.56 30.21 9.04 2.99 1 EKB 3203 PLANT AND EQUIPMENT DESIGN June 2018 CONFIDENTIAL 5/16 Table 3 Physical properties Vapor density (kg/m3) Liquid density (kg/m3) Volumetric flow rate (m/s) Plate spacing (mm) Distillate 16.05 383.89 0.0375 450 Bottom 25.79 393.57 0.0308 Based on the data given, design the distillation column by the following sequence: a) Calculate the mol fraction for feed, distillate and bottom in Table 2 (3 marks) b) Determine the number of theoretical stages (9 marks) c) Determine the number of actual stages (2 marks) d) From data given in Table 3, estimate the column height and column diameter at 85% of flooding velocity. (Consider the downcomer area is 12% of total) (13 marks)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts