Question: i need a summary about this case Global Logistics and Supply Chain Management: HP Case Study Executive Summary The presenk movement in manufacturing has driven

i need a summary about this case

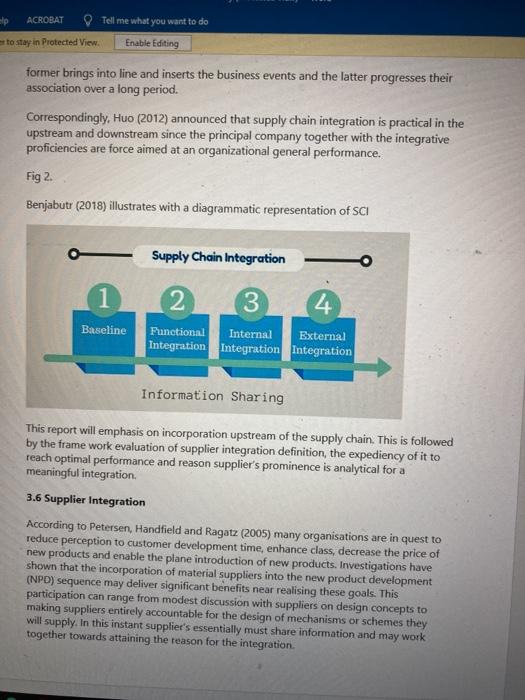

Global Logistics and Supply Chain Management: HP Case Study Executive Summary The presenk movement in manufacturing has driven businesses to outsourcing collaborating and creating a widespread network of suppliers in order to bring products to clients. Ataseven & Nair (2012) acknowledged supply chain integration rationalizes business development and direct processes which permits businesses to attain competitive advantage. Therefore, the necessity for pivotal businesses to build a relationship with a supplier (Lawson, Squire and Cousins, 2008) and acknowledging its competences as a supplier before integration After integrating with a supplier supply chain managers essentially must build a framework as a check on the supply chain as discussed by Christopher (2016) The analysis is about theories of supply chain management and current evaluations linking to the report The result of this report offered a critical evalution and analysis of supply chain management with the emphasis on upstream incorporation and using Hp incasa case study. Also, the findings gove understanding to why Hp Inc. is a top competitor in the PC manufacturing industry Lastly, the report endorses companies to have complete prominence and matute aligning interest by joining procedures with a supplier 1.0 Introduction This report is about Hewlett Packard Incorporated and its operations in the Supply Chain Business. The report will conduct a preliminary research about HP Inc and identify key issues and challenges currently faced by it. The report will look at the operations of the Stippliers, Distributors and Consumers of the supply chain at Hewlett Packard and figure out how is affected by these challenges The report will use supply chain management to analyse the issues and challenges and make recommendations, The report will look at when these challenges ocak The location of Hp inc suppliers their relationship, and strategies used in the supply chain. The types of transport for its aligning interest by joining procedures with a supplier. 1.0 Introduction This report is about Hewlett Packard Incorporated and its operations in the Supply Chain Business. The report will conduct a preliminary research about HP Inc. and identify key issues and challenges currently faced by it. The report will look at the operations of the Suppliers, Distributors and Consumers of the supply chain at Hewlett Packard and figure out how is affected by these challenges, The report will use supply chain management to analyse the issues and challenges and make recommendations. The report will look at when these challenges occur. The location of Hp Inc. suppliers, their relationship, and strategies used in the supply chain. The types of transport for its distribution and logistics service providers and look at product risk, vulnerability, robustness, resilience and reverse logistics from the consumer. 2.0 Overview of Hp Inc. According to Hp Inc. (2018) Hewlett Packard Incorporated is a maker of products, machineries, software, resolutions and services to distinct customers small and medium sized industries and large enterprises, Hp Inc operates through three business Segments: Personal Systems, Printing, and Corporate Investments. It operates across the Americas, Europe, the Middle East Africa and Asia Pacific HP has its headquarters in Palo Alto, California, the US Hp Inc. (2018) stated returns of 552,056 million for the fiscal year ended October 2017 an increase of 79% over FY2016. In FY2017. Hp's working boundary was 68% likened to a working boundary of 74% in FY2016. In FY2017, the company recorded a net margin machineries, software, resolutions and services to distinct customers, small and medium sized industries and large enterprises. Hp Inc. operates through three business segments: Personal Systems, Printing and Corporate Investments. It operates across the Americas, Europe, the Middle East, Africa and Asia-Pacific. HP has its headquarters in Palo Alto, California, the US. Hp Inc. (2018) stated returns of $52,056 million for the fiscal year ended October 2017 an increase of 7.9% over FY2016. In FY2017, Hp's working boundary was 6.8%, likened to a working boundary of 7.4% in FY2016. In FY2017, the company recorded a net margin of 4.9%, likened to a net margin of 5.2% in FY2016. Hp reported revenues of US$14,586.0 million for the third quarter ended July 2018, an upsurge of 4.2% over the previous quarter. 3.0 Literature Review The reports literature review is about supply chain management with emphasis on supply chain amalgamation 3.1 Outsourcing According to Mangan & Lalwani (2016) outsourcing is when any process or procedure that is usually done in-house by a company's personnel is sub-contracted to another establishment for an extensive period. The outsourced responsibilities can be done on- site or off-site. Outsourcing has its several rewards. As detailed by Mangon & Lalwani (2016), there are numerous motives a company would pursue to outsource. For instance, surge flexibility, having access to non core competence.cost decrease, direct, secondary, principal, taxes along with others to advance performance The gathering and management of all the suppliers associated in creating a produce or bringing a service is next to be discussed in supply chain management 3.2 Supply chain Management able to ung Exploration has come up with varying interpretation to supply chain management but with a common goal. Mangan & Lalwani (2016) claims that it is the management, across and inside a system of upstream and downstream groups, of both dealings and movements of material, data and resources. The significance of Supply Chain Management is to generate value, improve competence, and gratify customers. Van der Vorst (2004) is of the opinion that supply chain management is the combined preparation, organisation and control of the entire business method and events in the supply chain to deliver quality customer value at a cheap price to the supply chain while fulfilling standards of the other stakeholders in the supply chain. These connotation spreads to form an international system and upholding the method stream in the supply chain can be thought-provoking. On the contrary, Richards & Grinstead (2016) explained that a suitable supplier association development is an important component in supply chain management. In totalling, distinguishing features of top performing supply chains are the goals of companies in having an advantage over their opponents (Mangan and Lalwani, 2016). Correspondingly, Lindgreen et al., (2013) recommended that a supply chain manager needs to distinguish and concentrate suppliers that are mainly pivotal to the overall advantage of the company. A supportive view from Tseng (2014) said developing a strategic long-term association helps uphold anticipated performance that will impact competitive advantage. Mangan & Lalwani (2016) acknowledged the inclination in competitive advantage. To succeed in this area. The supply chain should be able to provide the right product, at the right product at the right price, to the right customer, in the right condition at the right time and right quantity, have witnessed supply chain links of global enterprises, occasionally develop issues upsetting supply chain performance. An example is a late delivery to the final customer or the production lead time. In the direction of which Muhammed (2018) dubbed the framework of dealing with the diverse suppliers as Suppliers Relationship Management (SRM). According to Webb (2017) SRM is basically the course for establishments shaping the supply groups that are significant and creating the tactics that bring about these matters in a smart fashion. SRM offer superior stages of innovation, improve value to a produce based on demand and progresses supply chain performance. Below is an illustration of Supply chain value flow. 3.3 Supply chain edito stay in Protected View Erable ting According to Rajgopal (2016) supply chain is the gathering of procedures and possessions essential to manufacturer and deliver a produce to the ultimate purchaser This view is supported by Janvier James (2012) and defines Supply Chain as planned manufacturing procedure in which raw resources are changed into complete goods, then brought to the end consumer. Rajgopal (2016) has established that supply chain has three unified parts Upstream, where obtaining or gaining from outside suppliers occurs. Midstream or Internal where manufacturing or assemblage happenis. Downstream, when distribution regularly by outside distributors and sales to the purchaser happens According to Mangan and Lalwani (2016) supply chain has various activities such as transport, warehousing, purchasing, marketing and finance, 3.4 Suppliers According to International trade (2018) suppliers are the party providing goods or services in a commercial deal in exchange for the agreed financial value. An explanation from Rajgopal, (2016) states that suppliers are the upstream of the supply chain The diagrammatic illustration above gives a perception to how supply chain relationships are shaped to generate competitive advantage, the requirement to hand- pick the correct associates and manage suppliers relationship to enhance performance Below is a review relating concepts on how to bring into line and manage with nominated suppliers to take full advantage of supply chain performance 3.5 Supply Chain Integration (SCI) Supply Chain Integration is the extent a principal company work together with their suppliers to successfully manage all procedures in generating value for goods and services to the final consumer (Flynn, Huo and Zhao, 2010). This is supported by Mangan, Lalwani, Butcher & lavadpour (2013) that supply chain integration represents numerous communication networks and associations inside the supply system Though. Mangan & Lalwani (2016) stressed that supply chain integration signifies influences within the supply system, also ought not be misguided for collaboration. They additionally clarified the variance among integration and collaboration by asserting the elp ACROBAT Tell me what you want to do to stay in Protected View Enable Editing former brings into line and inserts the business events and the latter progresses their association over a long period. Correspondingly, Huo (2012) announced that supply chain integration is practical in the upstream and downstream since the principal company together with the integrative proficiencies are force aimed at an organizational general performance. Fig 2. Benjabut (2018) illustrates with a diagrammatic representation of SCI o - Supply Chain Integration 1 2 3 4 Baseline Functional Internal External Integration Integration Integration Information Sharing This report will emphasis on incorporation upstream of the supply chain. This is followed by the frame work evaluation of supplier integration definition, the expediency of it to reach optimal performance and reason supplier's prominence is analytical for a meaningful integration 3.6 Supplier Integration According to Petersen, Handfield and Ragatz (2005) many organisations are in quest to reduce perception to customer development time, enhance class, decrease the price of new products and enable the plane introduction of new products. Investigations have shown that the incorporation of material suppliers into the new product development (NPD) sequence may deliver significant benefits near realising these goals. This participation can range from modest discussion with suppliers on design concepts to making suppliers entirely accountable for the design of mechanisms or schemes they will supply. In this instant supplier's essentially must share information and may work together towards attaining the reason for the integration Help ACROBAT Tell me what you want to do safer to stay in Protected View Enable Editing Huo (2012) states that internal integration progresses external integration besides internal and external integration directly and indirectly improves company output. Additionally, complete or fractional mediating effects between SCI and company output are recognised. Ataseven and Nair (2017) assets a prove of trust and confidence is built when key suppliers operations are linked to their internal operations and external demand. This suggests that the upstream combination firmly influence the supply chain and achieve best performance, supplier's prominence must be total, and visibility must cover the degree of combined links. An example is the principal establishment to their first Tiers. This was confirmed that present company's supply chain essentially should be Lean Agile, Robust and Sustainable in order to be modest in their individual markets. It also disclosed the intricate difficulties in choosing the right preparation to implement and gauges to calculate supply chain output (Cabral, Grilo and Cruz-Machado, 2012). The analyses and evaluation of current supply chain performance at Hp Inc. Piotrowicz and Cuthbertson (2011) states that supply chain performance measurement is a setting- independent process, personalised to precise supply chain necessities. To comprehend in what way a performance dimension system in a supply chain has been established and used, it necessitates to apprehend its setting, process and content. 3.7 Supply Chain Performance The investigation exposed numerous writers highlighting thoughtfulness relating to the supply chain performance. This is due to composite issues thought of in attempts to designing a background for calculating performance. As illustrated by Sillanpaa (2010) voiced that an establishment engages numerous actions to find their performance in the sale places nonetheless there are lesser scopes more important than others summing the overall performance. In this instance, the outcome of upstream combination that yields in swiftness of executions and lower price in manufacturing may be a vital performance factor in general. 4.0 Hp Business Practises and Strategies Overview Specific roles across the business initiative is a distributed approach, fetching in traditions that remain utmost importance to the aims and actions. These comprises of corporations, patronages, partnership on business initiatives, buyer and supplier instruction supplier abled structuring agendas, supplier reviews and valuations, session er to stay in Protected View Enable Editing contribution, worker reviews, mentoring and others. Hp Inc. finds suitable stakeholders built on reasons such as skill, readiness to cooperate, status, site, and scope of effect (hp.com, 2017). 4.1 Hp's Logistics and Supply Chain Management Hp use a momentous quantity of outsourced manufacturers (OMs") around the globe to produce HP-designed products. The usage of OMs is planned to create cost competences and decrease time to market for HP designed goods. It uses multiple OMs to preserve flexibility in its supply chain and manufacturing procedures. Occasionally, third-party suppliers manufacture goods that are bought and resold with HP brand. In addition to the use of OMs, in some occasions, limited number of products have been manufactured by Hp for their use instead of awaiting from third party suppliers (hp.com, 2017). Hp practises Leagile methods of satisfying customers request for products. The reason.is that Hp produce products to order to exploit industrial and logistics competences by manufacturing high bulks of elementary product formations. Otherwise, arranging products to order allows units to fit a client's hardware and software modification supplies (hp.com, 2017). Hp stock administration and distribution practices in both construction products to order and organising products to order pursue to lessen stock holding phases by taking hold of the inventory and producing it soon before the sale or distribution of goods to the client (hp.com, 2017). 4.2 Hp Current Performance According to hp.com (2017) Hp tactic to sustainability extends to a comprehensive array of sustainability matters made up of three columns: environment, society and integrity. It ranks matters to solve built on their comparative status to Hp's culture, commercial achievement and sustainable progress and long-term sustainable goals. 4.3 Climate change Use hundred percent renewable electricity in Hp global processes, with a provisional achievement of forty percent by 2020 (hp.com. 2017). 4.4 Natural Resources . ALROBA Tell me what you want to do It's safer to stay in Protected View Enable Editing . Attain zero deforestation related with HP product paper and paper-based product wrapping which includes the box that comes with the product and all paper inside the case by 2020 (hp.com, 2017). 5. Society Progress skills and advance well-being of five hundred thousand plant employees by 2025, from the commencement of 2015 (hp.com, 2017). . 4.6 Integrity Preserve larger than ninety nine percent achievement rate of Ethics of Professional Conduct training amongst regular HP staffs and the Board of Executives (hp.com, 2017). 5.0 Key Challenges Hp had constructed a supply chain visualization instrument in answer to receiving an improved grip on how to place supply chain visualization tool, such as straight ship actions. At the period, HP had perceptibility into their supply chain, but it needed the speed to link an occurrence to the system and retort properly. Fundamentally, it could realise an incident was happening, but remained incapable to make variations to their system to mitigate the harm. Hp knew what to do nonetheless could not get the material fast enough (LLamasoft, 2016). Though HP was in preparation to solve the speed issue, it also experienced an increase in interruptions. Hp noticed that climate associated issues have increased pointedly in current years. Since Hp was running lean, these interruptions made the hazard worse. The team took the visualization database and merged a risk management layer (Lamasoft, 2016). This then resolved the challenges faced. 6.0 Current Supply Chain Strategy According to (Llamasoft, 2016) HP provides challenging material from third party data bases into the tool. Forecasters screen and assess whether the challenge will influence the supply chain. The main threat for HP is the data it comprises of a complete customary of information of manufacturers and suppliers but have lapses. Hp is very poised with the information they have for Tier 1 suppliers, but then throws up challenges when it is detailed, the exactness becomes very challenging. This data is a link between HP manufacturing locations and suppliers that gives feedback to Hp regarding a disruption for products they vend straight to consumers