Question: I need answers to this discussion Case Study: Two Rods Don't Make It Right Hyatt Regency Walkway Collapse Source: System Failure Case Studies. National Aeronautics

I need answers to this discussion

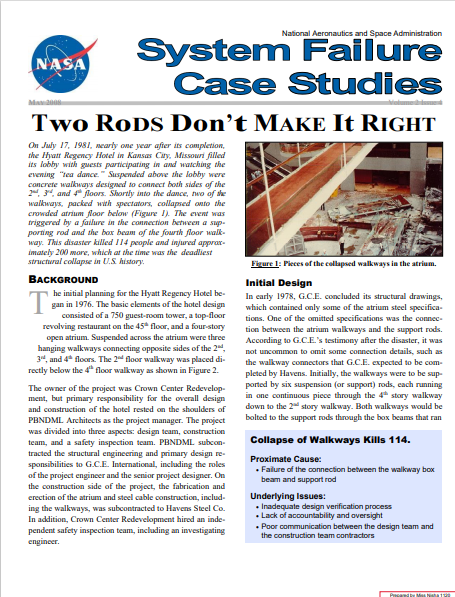

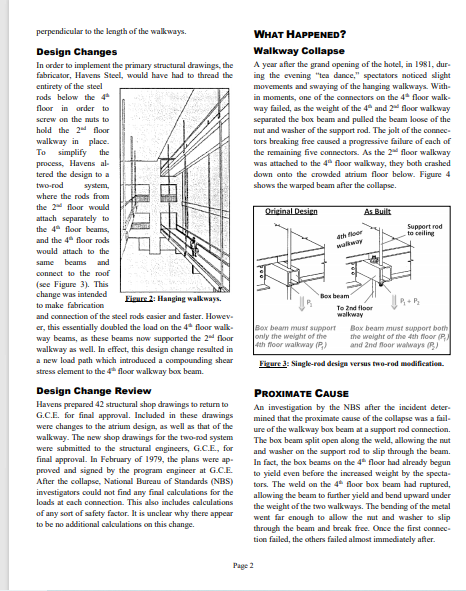

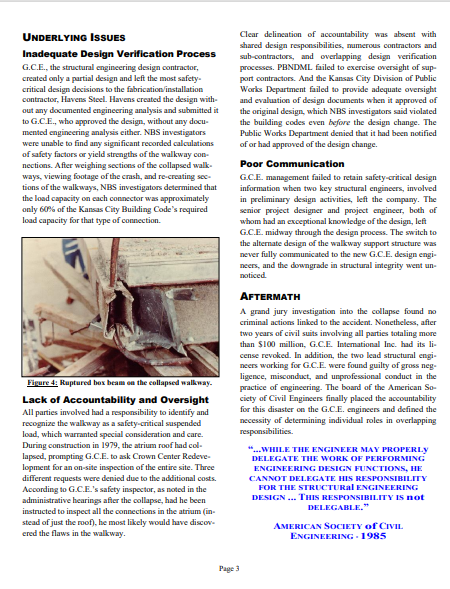

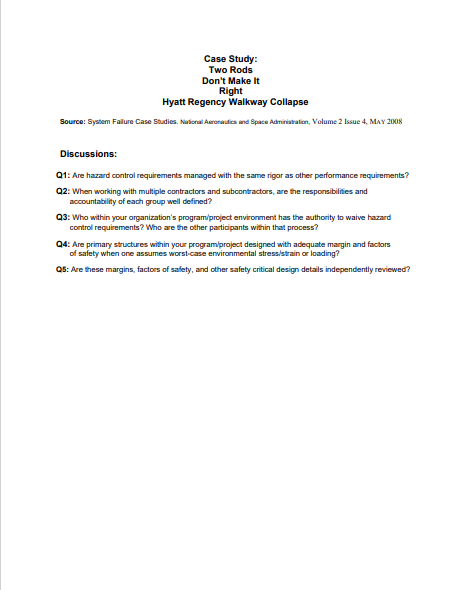

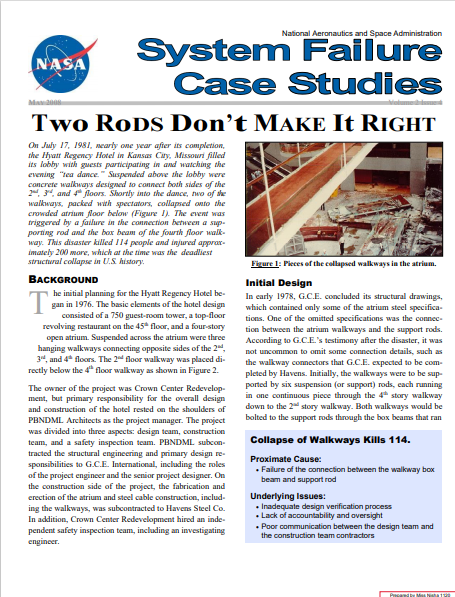

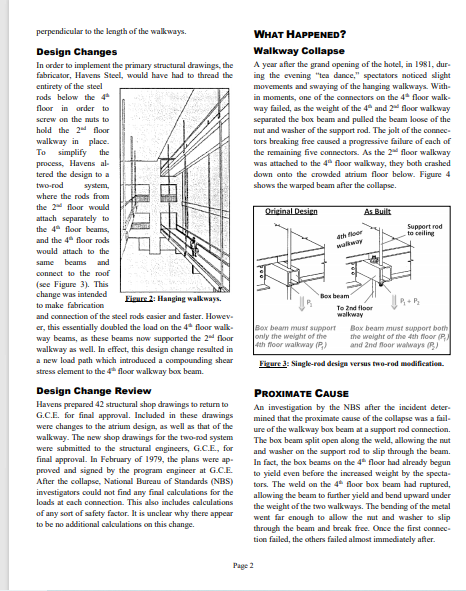

Case Study: Two Rods Don't Make It Right Hyatt Regency Walkway Collapse Source: System Failure Case Studies. National Aeronautics and Space Administration, Volume 2 Issue 4, MAY 2008 Discussions: Q1:Are hazard control requirements managed with the same rigor as other performance requirements? Q2: When working with multiple contractors and subcontractors are the responsibilities and accountability of each group well defined? Q3: Who within your organization's program/project environment has the authority to waive hazard control requirements? Who are the other participants within that process? Q4: Are primary structures within your program project designed with adequate margin and factors of safety when one assumes worst case environmental stress/strain or loading? Q5: Are these margins, factors of safety, and other safety critical design details independently reviewed? National Aeronautics and Space Administration System Failure NASA Case Studies Two Rods Don't MAKE It RIGHT T On July 17, 1981, nearly one year after its completion, the Hat Regency Hotel in Kansas Cay. Missouri filled its lobby with guests participating in and watching the evening "lea dance. Suspended above the lobby were concrete walkways designed to connect both sides of the 2. 3. and "floors. Shortly into the dance, two of the walkways, packed with spectators, collapsed onto the crowded arrim floor below (Figure 1). The event was triggered by a failure in the connection between a sup porting rod and the box beam of the fourth floor walk way. This disaster killed 114 people and injured apprar imately 200 mare, which ar the time was the deadliest structural collapse in US history, BACKGROUND he initial planning for the Hyatt Regency Hotel be- gan in 1976. The basic elements of the hotel design consisted of a 750 guest room tower, a top floor revolving restaurant on the 45 floor, and a four-story open atrium. Suspended across the atrium were three hanging walkways connecting opposite sides of the 2 3, and 4 floors. The floor walkway was placed di- rectly below the 4 floor walkway as shown in Figure 2. The owner of the project was Crown Center Redevelop ment, but primary responsibility for the overall design and construction of the hotel rested on the shoulders of PENDML Architects as the project manager. The project was divided into three aspects design team, construction team, and a safety inspection team. PANDML subcon tracted the structural engineering and primary design te sponsibilities to G.C.E. International, including the roles of the project engineer and the senior project designer. On the construction side of the project, the fabrication and crection of the atrium and steel cable construction, includ- ing the walkways, was subcontracted to Havens Steel Co. In addition, Crown Center Redevelopment hired an inde- pendent safety inspection team, including an investigating engineer. Figure 1: Pieces of the collapsed walkways in the atrium. Initial Design In early 1978, G.C.E. concluded its structural drawings, which contained only some of the atrium steel specifica- tions. One of the omitted specifications was the connec tion between the atrium walkways and the support rods. According to G.C.E.'s testimony after the disaster, it was not uncommon to omit some connection details, such as the walkway connectors that G.C.E. expected to be com- pleted by Havens. Initially, the walkways were to be sup- ported by six suspension (or support) rods, cach running in one continuous piece through the story walkway down to the 2 story walkway. Both walkways would be bolted to the support rods through the box beams that ran Collapse of Walkways kills 114. Proximate Cause: . Failure of the connection between the walkway box beam and support rod Underlying Issues: . Inadequate design verification process Lack of accountability and oversight . Poor communication between the design team and the construction team contractors P10 perpendicular to the length of the walkways. WHAT HAPPENED? Walkway Collapse A year after the grand opening of the hotel, in 1981, dur- ing the evening "tea dance," spectators noticed slight movements and swaying of the hanging walkways. With in moments, one of the connectors on the 4 floor walk- way failed, as the weight of the 4 and 2 floor walkway separated the box beam and pulled the beam loose of the nut and washer of the support rod. The jolt of the connec tors breaking free caused a progressive failure of each of the remaining five connectors. As the 2 floor walkway was attached to the 4 floor walkway, they both crashed down onto the crowded atrium floor below. Figure 4 shows the warped beam after the collapse Original Design As Built Support rod to ceiling ad walian Design Changes In order to implement the primary structural drawings, the fabricator, Havens Steel, would have had to thread the entirety of the steel rods below the 4 floor in order to screw on the nuts to hold the 2nd floor walkway in place. To simplify the process, Havens al tered the design to a two-rod system, where the rods from the 2 floor would attach separately to the 4 floor beams, and the 4 floor rods would attach to the same beams and connect to the roof (see Figure 3). This change was intended Figure 2. Hanging walkways. to make fabrication and connection of the steel rods easier and faster. Howev. cr, this essentially doubled the load on the 4 floor walk way beams, as these beams now supported the 2 floor walkway as well. In effect, this design change resulted in a new load path which introduced a compounding shear stress element to the floor walkway box beam. Design Change Review Havens prepared 42 structural shop drawings to return to G.C.E. for final approval. Included in these drawings were changes to the atrium design, as well as that of the walkway. The new shop drawings for the two-rod system were submitted to the structural engineers, G.C.E, for final approval. In February of 1979, the plans were ap- proved and signed by the program engineer at G.C.E. After the collapse, National Bureau of Standards (NBS) investigators could not find any final calculations for the loads at each connection. This also includes calculations of any sort of safety factor. It is unclear why there appear to be no additional calculations on this change. Box beam Tond floor walkway Box beam must support Box beam must support both only the weight of the the weight of the 4th floor 4th floor walkway P.) and 2nd floor walways B! Figure 3: Single-red design versus thoroddification PROXIMATE CAUSE An investigation by the NBS after the incident deter mined that the proximate cause of the collapse was a fail ure of the walkway box beam at a support rod connection. The box beam split open along the weld, allowing the nut and washer on the support rod to slip through the beam. In fact, the box beams on the 4 floor had already begun to yield even before the increased weight by the specta- tors. The weld on the floor box beam had ruptured, allowing the beam to further yield and bend upward under the weight of the two walkways. The bending of the metal went far enough to allow the nut and washer to slip through the beam and break free. Once the first connec- tion failed, the others failed almost immediately after. Page 2 UNDERLYING ISSUES Inadequate Design Verification Process G.C.E., the structural engineering design contractor, created only a partial design and left the most safety critical design decisions to the fabrication installation contractor, Havens Steel. Havens created the design with out any documented engineering analysis and submitted it to G.C.E., who approved the design, without any docu- mented engineering analysis either. NBS investigators were unable to find any significant recorded calculations of safety factors or yield strengths of the walkway con- nections. After weighing sections of the collapsed walk- ways, viewing footage of the crash, and re-creating sec tions of the walkways, NBS investigators determined that the load capacity on each connector was approximately only 60% of the Kansas City Building Code's required load capacity for that type of connection Clear delineation of accountability was absent with shared design responsibilities, numerous contractors and sub-contractors, and overlapping design verification processes. PENDML failed to exercise oversight of sup- port contractors. And the Kansas City Division of Public Works Department failed to provide adequate oversight and evaluation of design documents when it approved of the original design, which NRS investigators said violated the building codes even before the design change. The Public Works Department denied that it had been notified of or had approved of the design change. Poor Communication G.C.E. management failed to retain safety-critical design information when two key structural engineers, involved in preliminary design activities, left the company. The senior project designer and project engineer, both of whom had an exceptional knowledge of the design, left G.C.E.midway through the design process. The switch to the alternate design of the walkway support structure was never fully communicated to the new G.C.E. design engi- neers, and the downgrade in structural integrity went un noticed Figure 4: Ruptured box beam on the collapsed walkway. Lack of Accountability and Oversight All parties involved had a responsibility to identify and recognize the walkway as a safety-critical suspended load, which warranted special consideration and care. During construction in 1979, the atrium roof had col- lapsed, prompting G.C.E.to ask Crown Center Redeve- lopment for an on-site inspection of the entire site. Three different requests were denied due to the additional costs. According to G.C.E.'s safety inspector, as noted in the administrative hearings after the collapse, had he been instructed to inspect all the connections in the atrium (in stead of just the roof), he most likely would have discov ered the flaws in the walkway. AFTERMATH A grand jury investigation into the collapse found no criminal actions linked to the accident. Nonetheless, after two years of civil suits involving all parties totaling more than $100 million, G.C.E. Interational Inc. had its li- cense revoked. In addition, the two lead structural engi neers working for G.C.E. were found guilty of gross neg. ligence, misconduct, and unprofessional conduct in the practice of engineering. The board of the American So- ciety of Civil Engineers finally placed the accountability for this disaster on the G.C.E. engineers and defined the necessity of determining individual roles in overlapping responsibilities. "...WHILE THE ENGINEER MAY PROPERLY DELEGATE THE WORK OF PERFORMING ENGINEERING DESIGN FUNCTIONS, HE CANNOT DELEGATE HIS RESPONSIBILITY FOR THE STRUCTURAL ENGINEERING DESIGN ... THIS RESPONSIBILITY IS not DELEGABLE." AMERICAN SOCIETY of CIVIL ENGINEERING. 1985 Page 3 Questions for Discussion (cont) . Are primary structures within your program/project designed with adequate margin and factors of safety when one assumes worst-case environmental stress strain or loading? . Are these margins, factors of safety, and other safety critical design details independently reviewed? 51-61 Before the disaster, the city of Kansas City had a small subdivision of the Division of Public Works in place to review building plans. However, after the collapse, the city created a Codes Administration Department dedicat- ed to reviewing building plans. APPLICABILITY TO NASA The case underscores the need to incorporate Safety and Mission Assurance engineering support into design and design verification processes. Of particular importance is carly incorporation of system safety activities, including 1) identification of hazards; 2) identification of control and/or mitigation measures and 3) specification of me thods to verify controls have been implemented. Further, the case reminds NASA engineers and program teams to develop an in-depth understanding of concepts such as yield, margin, and factors of safety when working with safety-critical structures. The case also underscores the need for requirements ownership, requirements clarity, and requirements change control. Ambiguity associated with overlapping responsibilities, matrixed support rela- tionships, and complex supply chains must be overcome by implementation of rigorous configuration management with formal requirement change boards that include inde pendent engineering and assurance representation. It must be remembered that responsibility is ultimately not deleg. able. Finally, it is important to consider how big projects can and do fail when small details are overlooked. The case examined a single system failure within the context of a 750-room hotel project, which one can reasonably assume included innumerable safety-critical design de tails and decisions. The sheer magnitude of the undertak ing further underscores the need for disciplined design- build processes that include appropriate independent re- viewers to ensure that every single safety-critical detail is addressed with rigor and care. Questions for Discussion . Are hazard control requirements managed with the same rigor as other performance requirements? . When working with multiple contractors and sub- contractors, are the responsibilities and accountability of each group well defined? . Who within your organization's programproject environment has the authority to waive hazard control requirements? Who are the other participants within that process? References Luth. Gregory P. Carology and Context of the Hyatt Regency Cd apie "Jumal of Perfomance of Centrale Facilities May 2000, 1981: Kansas City Hyw Regency Skywalk Collapos. Enig Ehics: An In Perspecte "Engineering Ethicx The Kanica Cay Hyatt Regency Walkwaya Col- lupie. "Depuiment of Philosophy and Depariment of Mechanical En gineering Texas A&M University Intipetic.tm.edu.thibabyatil.bim Macuri Board for Architects, Profesional Engineers and Land Sur veyor Daniel M. Duncan, Jack D. Gillum, and G.C.E.Inieman al, Inc. Administrative Hearing Commission. 1985. Case No. AR-84- 02:30 "Walkway College." Engineering.com http://www.mineering.com.my/ArticlePapelabid Pelb Lowery Jr., Lee. Hecc of the Colupeod Walkway, Ruplured Box Beam, Online lattpelliethics.tum.cdw ethics by att hyat2.htm. Accomod August 2007 Pinang, EO anal Marshall, R., Hanging Wallway (age). Collapse of the Kansas City Hall Regeny Wakwy, Civil Engineering ASCE, July 1982.52.65-68 Single-Red Design vs. Two-Red Modification Online images) www.co-bulman.cdw Claw HTML publicamenteld Winter'-97/imagegil, image2.gif Accord August 2007 SYSTEM FAILURE CASE STUDIES A product of the NABA Safety Center Esecutive Editor Steve Wander stephen.m.wanderas.gov Developed by ARES Corporation This is a NASA was trahing document conforme for available in the public domain. The finding process and cons ing factor died in this case study da nastaly pre hor of the Agency. Section of the camere derived from multiple sources der Raluca Ayrton aritpropera of suce materia To view the document cliendile to find additional System Failure Case Studies, go to http:/ NASA SAFETY CENTER Page 4