Question: I need help with question one option 3 and 2 01: Ollah's Organic Pet Ship sells about 4000 bags of free-range dog biscuits every year.

I need help with question one option 3 and 2

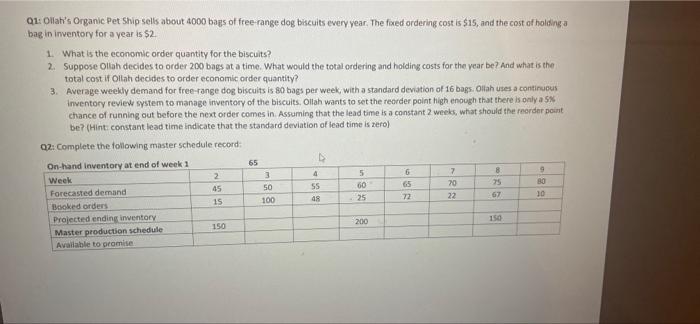

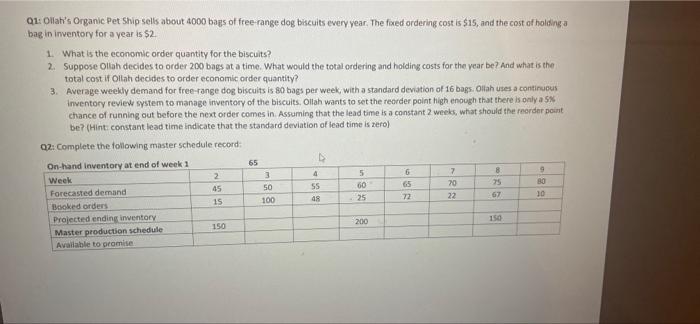

01: Ollah's Organic Pet Ship sells about 4000 bags of free-range dog biscuits every year. The fixed ordering cost is $15, and the cost of holding a bag in inventory for a year is $2 1. What is the economic order quantity for the biscuits? 2. Suppose Olloh decides to order 200 bags at a time. What would the total ordering and holding costs for the year be? And what is the total cost if Ollah decides to order economic order quantity? 3. Average weekly demand for free-range dog biscuits is 80 bags per week, with a standard deviation of 16 bags. Oltah uses a continuous Inventory review system to manage inventory of the biscuits. Ollah wants to set the reorder point high enough that there is only a 5% chance of running out before the next order comes in. Assuming that the lead time is a constant 2 weeks, what should the reorder point be? (Hint constant lead time indicate that the standard deviation of lead time is zero) Q2: Complete the following master schedule record: 4 6 . in 65 3 50 100 2 45 15 5 60 25 65 SS 7 70 22 9 B0 10 25 67 B 48 72 On-hand Inventory at end of week 1 Week Forecasted demand Booked orders Projected ending inventory Master production schedule Available to promise 200 150 01: Ollah's Organic Pet Ship sells about 4000 bags of free-range dog biscuits every year. The fixed ordering cost is $15, and the cost of holding a bag in inventory for a year is $2 1. What is the economic order quantity for the biscuits? 2. Suppose Olloh decides to order 200 bags at a time. What would the total ordering and holding costs for the year be? And what is the total cost if Ollah decides to order economic order quantity? 3. Average weekly demand for free-range dog biscuits is 80 bags per week, with a standard deviation of 16 bags. Oltah uses a continuous Inventory review system to manage inventory of the biscuits. Ollah wants to set the reorder point high enough that there is only a 5% chance of running out before the next order comes in. Assuming that the lead time is a constant 2 weeks, what should the reorder point be? (Hint constant lead time indicate that the standard deviation of lead time is zero) Q2: Complete the following master schedule record: 4 6 . in 65 3 50 100 2 45 15 5 60 25 65 SS 7 70 22 9 B0 10 25 67 B 48 72 On-hand Inventory at end of week 1 Week Forecasted demand Booked orders Projected ending inventory Master production schedule Available to promise 200 150

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock