Question: I need help with questions # 5 to # 10 only. thanks True False 1. A six-sigma method to quality management was developed by Japanese

I need help with questions # 5 to # 10 only. thanks

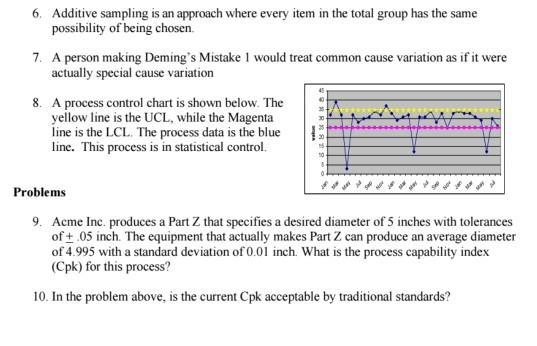

True False 1. A six-sigma method to quality management was developed by Japanese companies in the 1950s. 2. The full costs of quality are typically identified by the accounting department. 3. The use of traditional inspection to improve the quality of the process was discouraged by several TQM gurus 4. A formal service quality evaluation process measures the differences between service expectations and performance perceptions. 5. An effective supplier certification mechanism within the company will generally improve the quality, but typically at a higher purchase price. 6. Additive sampling is an approach where every item in the total group has the same possibility of being chosen 7. A person making Deming's Mistake I would treat common cause variation as if it were actually special cause variation 8. A process control chart is shown below. The yellow line is the UCL, while the Magenta line is the LCL. The process data is the blue line. This process is in statistical control. Problems 9. Acme Inc. produces a Part Z that specifies a desired diameter of 5 inches with tolerances of +.05 inch. The equipment that actually makes Part Z can produce an average diameter of 4.995 with a standard deviation of 0.01 inch. What is the process capability index (Cpk) for this process? 10. In the problem above, is the current Cpk acceptable by traditional standards? 6. Additive sampling is an approach where every item in the total group has the same possibility of being chosen 7. A person making Deming's Mistake I would treat common cause variation as if it were actually special cause variation 8. A process control chart is shown below. The yellow line is the UCL, while the Magenta line is the LCL. The process data is the blue line. This process is in statistical control. 0 Problems 9. Acme Inc. produces a Part Z that specifies a desired diameter of 5 inches with tolerances of +05 inch. The equipment that actually makes Part Z can produce an average diameter of 4.995 with a standard deviation of 0.01 inch. What is the process capability index (Cpk) for this process? 10. In the problem above, is the current Cpk acceptable by traditional standards

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock