Question: I need the answer of this case study. I need only the discuss and summary of this case study within 500 words.please solve it quickly

I need the answer of this case study. I need only the discuss and summary of this case study within 500 words.please solve it quickly

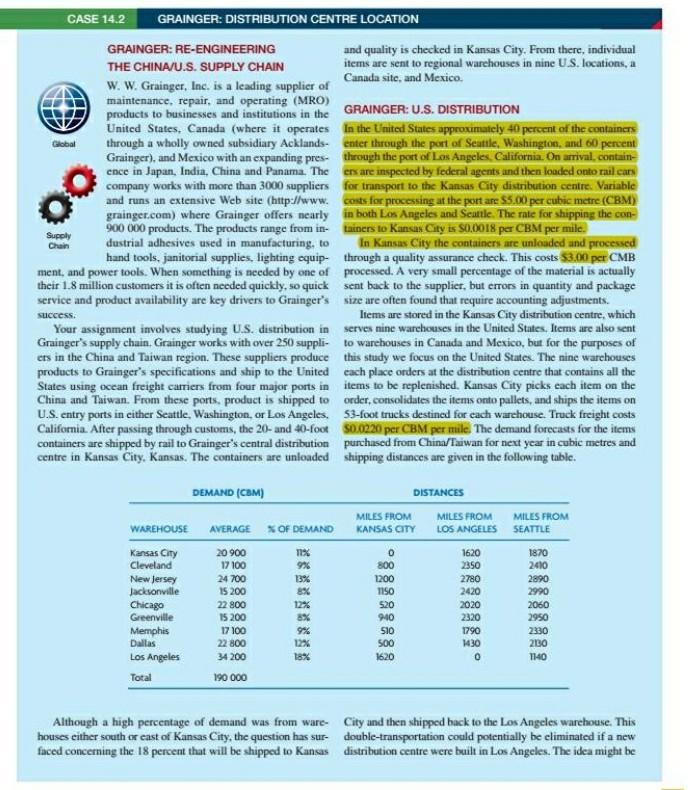

V E CASE 14.2 GRAINGER: DISTRIBUTION CENTRE LOCATION GRAINGER: RE-ENGINEERING and quality is checked in Kansas City. From there, individual THE CHINA/U.S. SUPPLY CHAIN items are sent to regional warehouses in nine US. locations, a W. W. Grainger, Inc. is a leading supplier of Canada site, and Mexico maintenance, repair, and operating (MRO) products to businesses and institutions in the GRAINGER: U.S. DISTRIBUTION United States, Canada (where it operates in the United States approximately 40 percent of the containers through a wholly owned subsidiary Acklands- enter through the port of Seattle, Washington, and 60 percent Grainger), and Mexico with an expanding pres through the port of Los Angeles, California. On arrival. contain- ence in Japan, India, China and Panama. The ers are inspected by federal agents and then loaded onto rail cars company works with more than 3000 suppliers for transport to the Kansas City distribution centre. Variable and runs an extensive Web site (http://www.costs for processing at the port are $5.00 per cubic metre (CBM) grainger.com) where Grainger offers nearly in both Los Angeles and Seattle. The rate for shipping the con 900 000 products. The products range from in- tainers to Kansas City is $0.0018 per CBM per mile. Supply dustrial adhesives used in manufacturing, to In Kansas City the containers are unloaded and processed hand tools, janitorial supplies, lighting equip through a quality assurance check. This costs $3,00 per CMB ment, and power tools. When something is needed by one of processed. A very small percentage of the material is actually their 1.8 million customers it is often needed quickly, so quick sent back to the supplier, but errors in quantity and package service and product availability are key drivers to Grainger's size are often found that require accounting adjustments. success. Items are stored in the Kansas City distribution centre, which Your assignment involves studying U.S. distribution in serves nine warehouses in the United States. Items are also sent Grainger's supply chain. Grainger works with over 250 suppli- to warehouses in Canada and Mexico, but for the purposes of ets in the China and Taiwan region. These suppliers produce this study we focus on the United States. The nine warehouses products to Grainger's specifications and ship to the United each place orders at the distribution centre that contains all the States using ocean freight carriers from four major ports in items to be replenished. Kansas City picks each item on the China and Taiwan. From these ports, product is shipped to order, consolidates the items onto pallets, and ships the items on U.S. entry ports in either Seattle, Washington, or Los Angeles. 53-foot trucks destined for each warehouse. Truck freight costs California. After passing through customs, the 20-and 40-foot 50.0220 per CBM per mile. The demand forecasts for the items containers are shipped by rail to Grainger's central distribution purchased from China/Taiwan for next year in cubic metres and centre in Kansas City, Kansas. The containers are unloaded shipping distances are given in the following table. DEMAND (COM) DISTANCES MILES FROM MILES FROM MILES FROM WAREHOUSE AVERAGE OF DEMAND KANSAS CITY LOS ANGELES SEATTLE Kansas City 20 900 11% 1620 1870 Cleveland 17100 9% 800 2350 2410 New Jersey 24 700 13% 1200 2780 2890 Jacksonville 15200 8% TISO 2420 2990 Chicago 22 800 12% 520 2020 2060 Greenville 15200 8% 940 2320 2950 Memphis 17 100 9% 510 1790 2330 Dallas 22 800 500 1430 200 Los Angeles 34200 18% 1620 0 1140 Total 190 000 Although a high percentage of demand was from ware City and then shipped back to the Los Angeles warehouse. This houses either south or cast of Kansas City, the question has sur double-transportation could potentially be eliminated if a new faced concerning the 18 percent that will be shipped to Kansas distribution centre were built in Los Angeles. The idea might be CASE 14.2 GRAINGER: DISTRIBUTION CENTRE LOCATION to ship material arriving at the Seattle port by rail to a new Los Los Angeles and the federal part processing fee at both lo Angeles distribution centre, which would be located at the cur- cations is $5.00 per CBM. Assume that everything is trans- rent location of the Los Angeles warehouse ferred to the Kansas City distribution centre by rail, where it It is estimated that the Los Angeles facility could be up- is unloaded and quality checked. Assume that all volume is graded at a one-time cost of 1 500 000 and then operated for then transferred by truck to the nine existing warehouses in 5350 000 per year. In the new Los Angeles distribution centre, the United States containers would be unloaded and processed through a quality 2. Consider the idea of upgrading the Los Angeles ware- assurance check, just as is now done in Kansas City. The vari- house to include a distribution centre capable of process- able cost for doing this would be $5.00 per CBM processed ing all the volume coming into the United States. Assume which includes the cost to move the containers from the Los that the original containers coming into Seattle would be Angeles port to the distribution centre shipped by rail to Los Angeles. All volume would be un- After the material is processed in Los Angeles, the amount loaded and quality checked in Los Angeles. Eighteen per needed to replenish the Los Angeles warehouse (approxi- cent of the volume would then be kept in Los Angeles for mately 18 percent) would be kept and the rest sent by rail to distribution through that warehouse and the rest shipped Kansas City. It would then be directly stocked in the Kansas by rail to the Kansas City warehouse. The cost to ship to City distribution centre and used to replenish the warehouses. Kansas City would be 50.0018 per CBM. The material They expect that very little would need to be shipped back to sent to Kansas City would not need to go through the "un- the Los Angeles warehouse after the new system was operating load and quality check process," and would be stored di- for about six months rectly in the Kansas City distribution centre. Assume that Grainger management feels that it may be possible to make the remaining volume would be transferred by truck to the this change, but they are not sure if it would actually save any eight remaining warehouses in the United States at a cost money and whether it would be a good strategic change. of $0.0220 per CBM 3. What should be done based on your analysis of the U.S. SPECIFIC QUESTIONS TO ADDRESS distribution system? Should the new Los Angeles distribu- IN YOUR ANALYSIS tion centre he added? Is there any obvious change that Grainger might do to make this option more attractive? 1. Relative to the U.S. distribution network, calculate the costs 4. Is this strategically something that Grainger should do? associated with running the existing system. Assume that What have they not considered that may be important? 40 percent of the volume arrives in Seattle and 60 percent in Segree: Based on a scenario developed in Gary Scalzitti and Amuitahtu Sinha Granger Reengineering an international Supply Chain" Case Study No. 1429654 Tauber institute for Global Operations University of Michigan, Ann Arbor, ML 2010. The data in this case have been developed for teaching purperes and do not represent the actual situation at Grainget. The data, though. are representative of an taal problem that Grainger and similar companies mest address to run the supply chain cificitlyStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts