Question: I need the following: 1) The table created with columns of the decision variables, constraints. (It helps me understand better). 1) All the Decision variables

I need the following: 1) The table created with columns of the decision variables, constraints. (It helps me understand better). 1) All the Decision variables of the problems along with the explanation to why have we chose those. 2) The objective function equation along with the explanation. 3) All constraints equations along with the explanation and types of constraints mentioned with examples. 4) The step by step explanation and solution on how to solve the question and minimise the cost. 5) The network model of the problems with all the nodes and arcs along with the amount of earth moved through the arc and the costs mentioned. 6) Steps to use excel solver as well to solve this questions along with the explanation. 7) How are bulldozers used/transferred between sites 8) How many truck loads are transported between sites 9) What are the different costs 10) Is the prepositioning of bulldozers a good one.

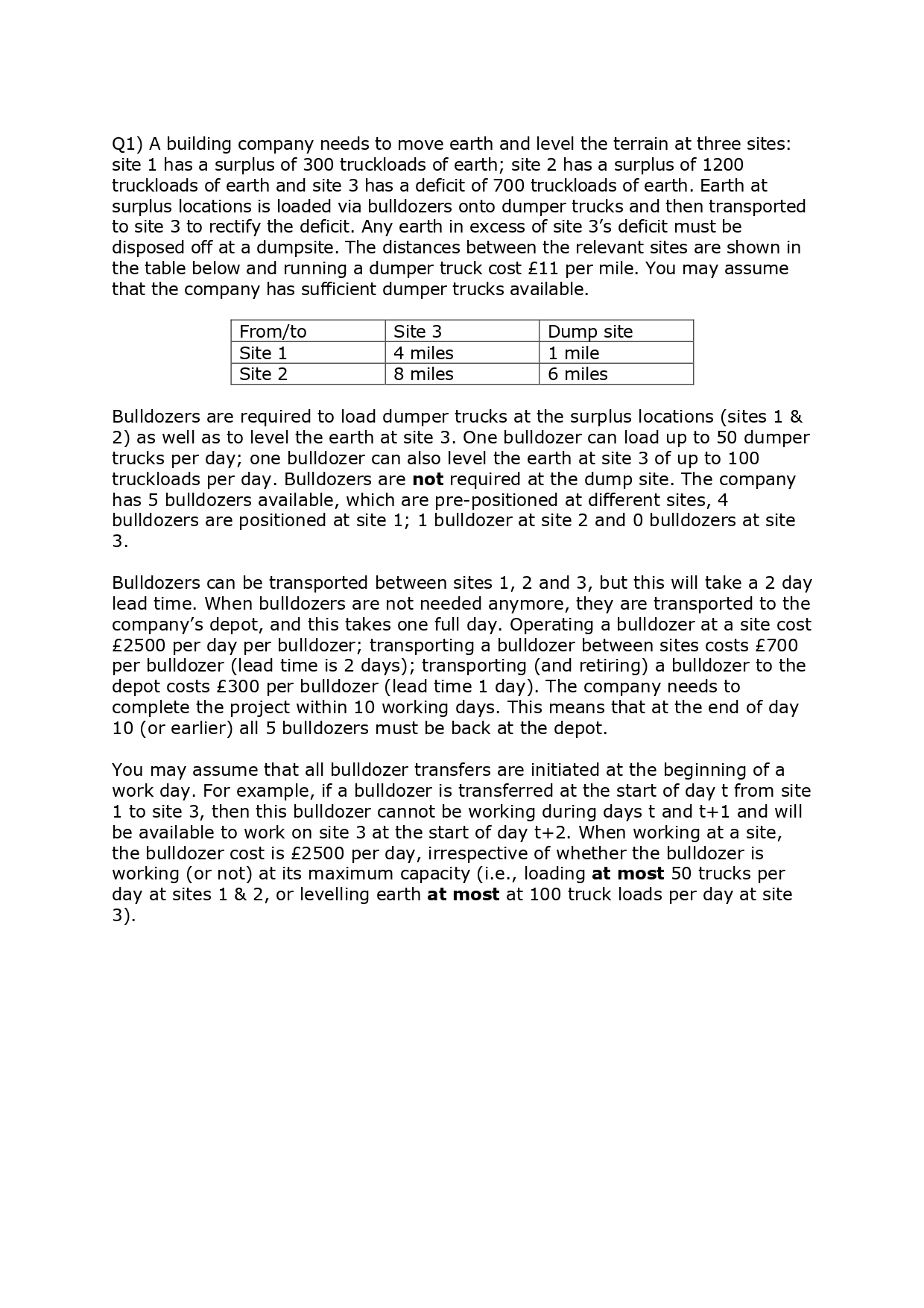

Q1) A building company needs to move earth and level the terrain at three sites: site 1 has a surplus of 300 truckloads of earth; site 2 has a surplus of 1200 truckloads of earth and site 3 has a deficit of 700 truckloads of earth. Earth at surplus locations is loaded via bulldozers onto dumper trucks and then transported to site 3 to rectify the deficit. Any earth in excess of site 3's deficit must be disposed off at a dumpsite. The distances between the relevant sites are shown in the table below and running a dumper truck cost 11 per mile. You may assume that the company has sufficient dumper trucks available. Bulldozers are required to load dumper trucks at the surplus locations (sites 1& 2 ) as well as to level the earth at site 3 . One bulldozer can load up to 50 dumper trucks per day; one bulldozer can also level the earth at site 3 of up to 100 truckloads per day. Bulldozers are not required at the dump site. The company has 5 bulldozers available, which are pre-positioned at different sites, 4 bulldozers are positioned at site 1; 1 bulldozer at site 2 and 0 bulldozers at site 3. Bulldozers can be transported between sites 1,2 and 3, but this will take a 2 day lead time. When bulldozers are not needed anymore, they are transported to the company's depot, and this takes one full day. Operating a bulldozer at a site cost 2500 per day per bulldozer; transporting a bulldozer between sites costs 700 per bulldozer (lead time is 2 days); transporting (and retiring) a bulldozer to the depot costs 300 per bulldozer (lead time 1 day). The company needs to complete the project within 10 working days. This means that at the end of day 10 (or earlier) all 5 bulldozers must be back at the depot. You may assume that all bulldozer transfers are initiated at the beginning of a work day. For example, if a bulldozer is transferred at the start of day t from site 1 to site 3 , then this bulldozer cannot be working during days t and t+1 and will be available to work on site 3 at the start of day t+2. When working at a site, the bulldozer cost is 2500 per day, irrespective of whether the bulldozer is working (or not) at its maximum capacity (i.e., loading at most 50 trucks per day at sites 1&2, or levelling earth at most at 100 truck loads per day at site 3)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts