Question: ****I only need help figuring out the correct formula for the cell that is coming back as an error**** Here is the information: Here is

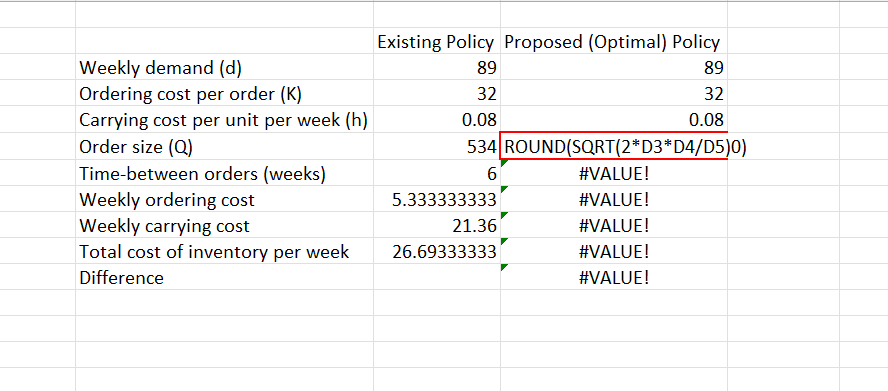

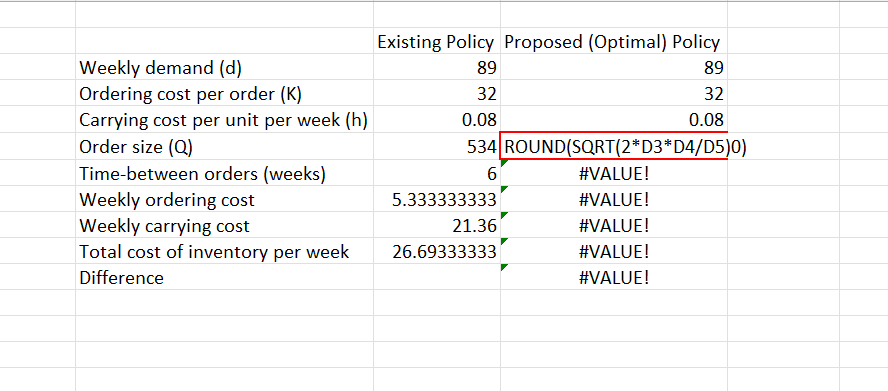

****I only need help figuring out the correct formula for the cell that is coming back as an error**** Here is the information:  Here is what I have in Excel...you will see the error in the D column, which is what I need help with. All the other numbers seem to be correct and all of the formulas elsewhere seem okay.

Here is what I have in Excel...you will see the error in the D column, which is what I need help with. All the other numbers seem to be correct and all of the formulas elsewhere seem okay.

Again, I just need help figuring out what's going wrong in my Excel sheet. Thank you

Again, I just need help figuring out what's going wrong in my Excel sheet. Thank you

1 1 2 100% + @ Project 4 - Inventory Control UPD MANUFACTURING UPD Manufacturing produces a range of health care appliances for hospital as well as for home use. The company has experienced a steady demand for its products, which are highly regarded in the health care field. Recently the company has undertaken a review of its inventory ordering procedures as part of a larger effort to reduce costs. One of the company's products is a blood pressure testing kit. UPD manufactures all of the components for the kit in-house except for the digital display unit. The display units are ordered at six-week intervals from the supplier. This ordering system began about five years ago, because the supplier insisted on it. However, that supplier was bought out by another supplier about a year ago, and the six-week ordering requirement is no longer in place. Nonetheless, UPD has continued to use the six-week ordering policy. According to purchasing manager Tom Chambers, "Unless somebody can give me a reason for changing, I'm going to stick with what we've been doing. I don't have time to reinvent the wheel." Further discussions with Tom revealed a cost of $32 to order and receive a shipment of display units from the supplier. The company assembles 89 kits a week. Also, information from Sara James, in Accounting, indicated a weekly carrying cost of $.08 for each display unit. The supplier has been quite reliable with deliveries; orders are received five working days after they are faxed to the supplier. Tom indicated that as far as he was concerned, lead-time variability is virtually nonexistent. Weekly demand (d) Ordering cost per order (K) Carrying cost per unit per week (h) Order size (Q) Time-between orders (weeks) Weekly ordering cost Weekly carrying cost Total cost of inventory per week Difference Existing Policy Proposed (Optimal) Policy 89 89 32 32 0.08 0.08 534 ROUND(SQRT(2*D3* D4/D5)0) 6 #VALUE! 5.333333333 #VALUE! 21.36 #VALUE! 26.69333333 #VALUE! #VALUE

Here is what I have in Excel...you will see the error in the D column, which is what I need help with. All the other numbers seem to be correct and all of the formulas elsewhere seem okay.

Here is what I have in Excel...you will see the error in the D column, which is what I need help with. All the other numbers seem to be correct and all of the formulas elsewhere seem okay.  Again, I just need help figuring out what's going wrong in my Excel sheet. Thank you

Again, I just need help figuring out what's going wrong in my Excel sheet. Thank you