Question: Imagine comparing a manufacturing operation using regular lot - sizing and the same operation with a kanban / lean production approach. What would be your

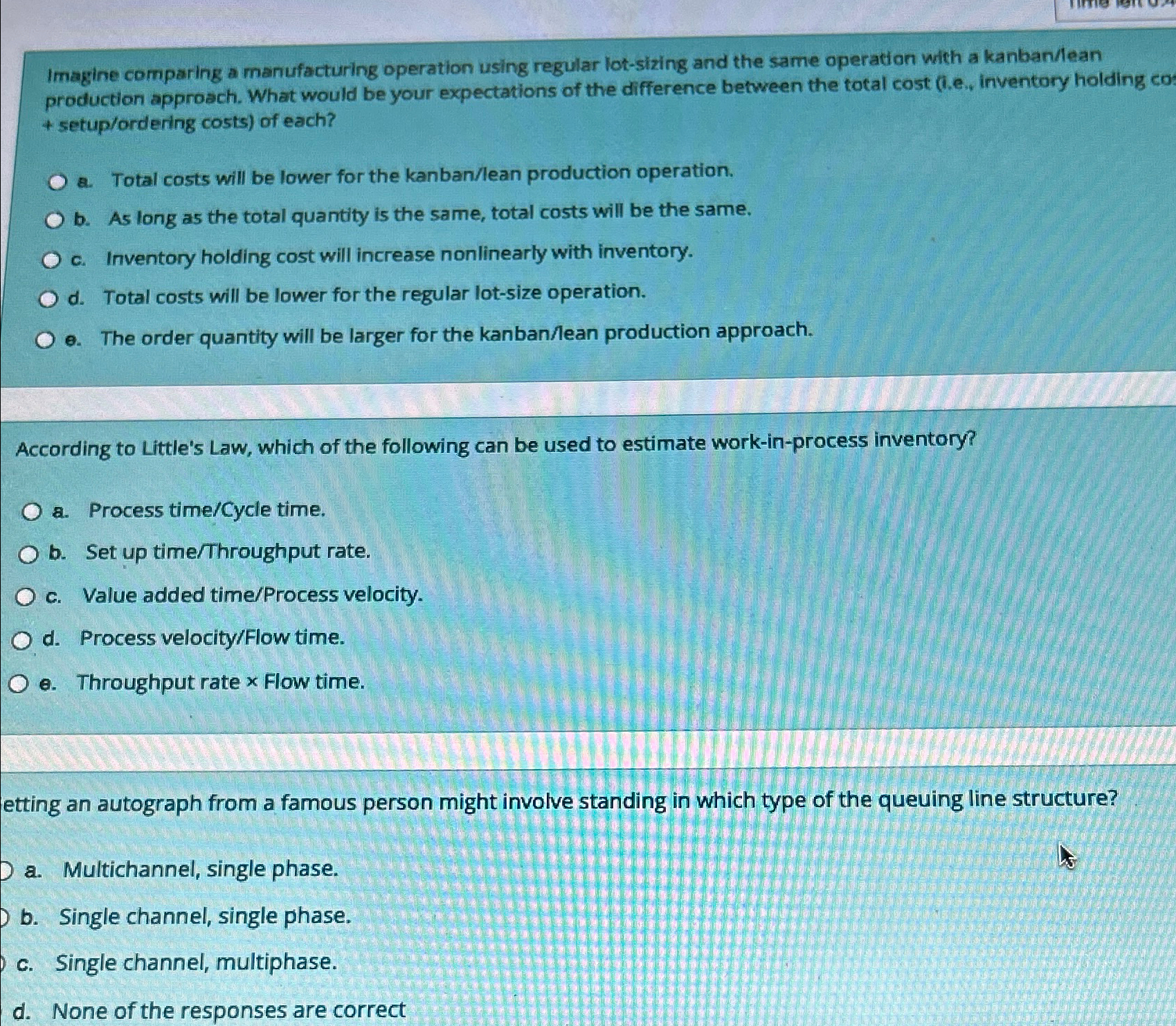

Imagine comparing a manufacturing operation using regular lotsizing and the same operation with a kanbanlean production approach. What would be your expectations of the difference between the total cost ie inventory holding co: setupordering costs of each?

a Total costs will be lower for the kanbanlean production operation.

b As long as the total quantity is the same, total costs will be the same.

c Inventory holding cost will increase nonlinearly with inventory.

d Total costs will be lower for the regular lotsize operation.

e The order quantity will be larger for the kanbanlean production approach.

According to Little's Law, which of the following can be used to estimate workinprocess inventory?

a Process timeCycle time.

b Set up timeThroughput rate.

c Value added timeProcess velocity.

d Process velocityFlow time.

e Throughput rate Flow time.

etting an autograph from a famous person might involve standing in which type of the queuing line structure?

a Multichannel, single phase.

b Single channel, single phase.

c Single channel, multiphase.

d None of the responses are correct

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock