Question: Important: You must submit your completed M11 Assignment Process Layout Problem Excel file for full credit for the problem. 2. An assembly line to be

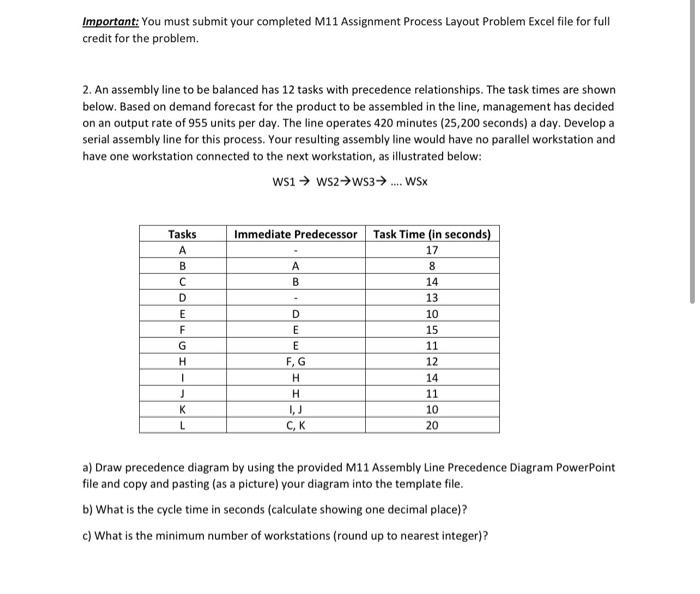

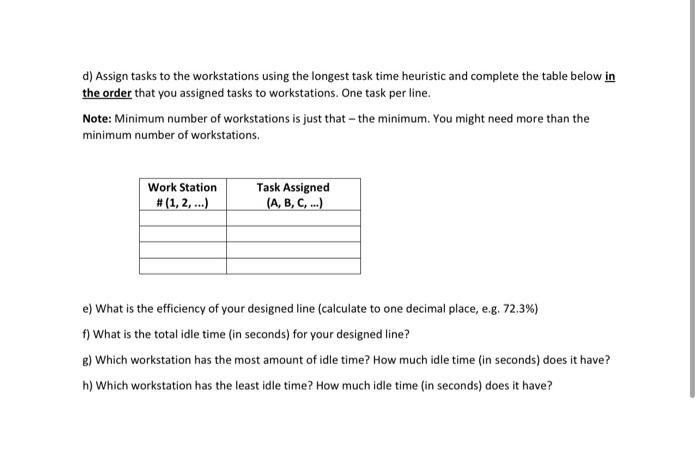

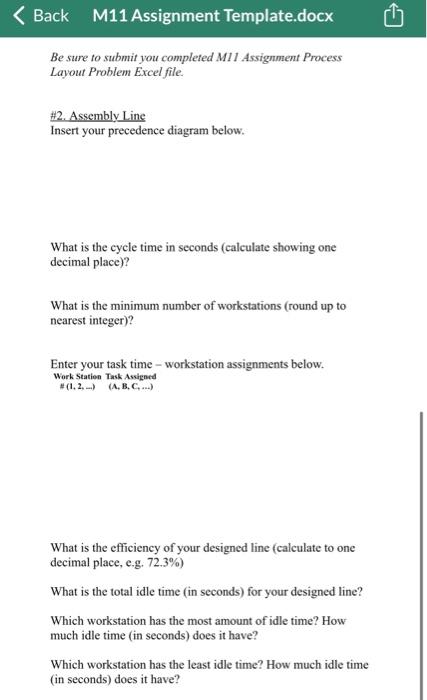

Important: You must submit your completed M11 Assignment Process Layout Problem Excel file for full credit for the problem. 2. An assembly line to be balanced has 12 tasks with precedence relationships. The task times are shown below. Based on demand forecast for the product to be assembled in the line, management has decided on an output rate of 955 units per day. The line operates 420 minutes (25,200 seconds) a day. Develop a serial assembly line for this process. Your resulting assembly line would have no parallel workstation and have one workstation connected to the next workstation, as illustrated below: WS1wS2WS3.WSx a) Draw precedence diagram by using the provided M11 Assembly Line Precedence Diagram PowerPoint file and copy and pasting (as a picture) your diagram into the template file. b) What is the cycle time in seconds (calculate showing one decimal place)? c) What is the minimum number of workstations (round up to nearest integer)? d) Assign tasks to the workstations using the longest task time heuristic and complete the table below in the order that you assigned tasks to workstations. One task per line. Note: Minimum number of workstations is just that - the minimum. You might need more than the minimum number of workstations. e) What is the efficiency of your designed line (calculate to one decimal place, e.g. 72.3\%) f) What is the total idle time (in seconds) for your designed line? g) Which workstation has the most amount of idle time? How much idle time (in seconds) does it have? h) Which workstation has the least idle time? How much idle time (in seconds) does it have? Be sure to submit you completed MII Assignment Process Layout Problem Excel file. \#2. Assembly Line Insert your precedence diagram below. What is the cycle time in seconds (calculate showing one decimal place)? What is the minimum number of workstations (round up to nearest integer)? Enter your task time - workstation assignments below. Work Station Task Assigned (1,2,)(A,B,C,) What is the efficiency of your designed line (calculate to one decimal place, e.g. 72.3\%) What is the total idle time (in seconds) for your designed line? Which workstation has the most amount of idle time? How much idle time (in seconds) does it have? Which workstation has the least idle time? How much idle time (in seconds) does it have? 4:52 .1 49 M11 Assembly Line Precedence Diagra... Important: You must submit your completed M11 Assignment Process Layout Problem Excel file for full credit for the problem. 2. An assembly line to be balanced has 12 tasks with precedence relationships. The task times are shown below. Based on demand forecast for the product to be assembled in the line, management has decided on an output rate of 955 units per day. The line operates 420 minutes (25,200 seconds) a day. Develop a serial assembly line for this process. Your resulting assembly line would have no parallel workstation and have one workstation connected to the next workstation, as illustrated below: WS1wS2WS3.WSx a) Draw precedence diagram by using the provided M11 Assembly Line Precedence Diagram PowerPoint file and copy and pasting (as a picture) your diagram into the template file. b) What is the cycle time in seconds (calculate showing one decimal place)? c) What is the minimum number of workstations (round up to nearest integer)? d) Assign tasks to the workstations using the longest task time heuristic and complete the table below in the order that you assigned tasks to workstations. One task per line. Note: Minimum number of workstations is just that - the minimum. You might need more than the minimum number of workstations. e) What is the efficiency of your designed line (calculate to one decimal place, e.g. 72.3\%) f) What is the total idle time (in seconds) for your designed line? g) Which workstation has the most amount of idle time? How much idle time (in seconds) does it have? h) Which workstation has the least idle time? How much idle time (in seconds) does it have? Be sure to submit you completed MII Assignment Process Layout Problem Excel file. \#2. Assembly Line Insert your precedence diagram below. What is the cycle time in seconds (calculate showing one decimal place)? What is the minimum number of workstations (round up to nearest integer)? Enter your task time - workstation assignments below. Work Station Task Assigned (1,2,)(A,B,C,) What is the efficiency of your designed line (calculate to one decimal place, e.g. 72.3\%) What is the total idle time (in seconds) for your designed line? Which workstation has the most amount of idle time? How much idle time (in seconds) does it have? Which workstation has the least idle time? How much idle time (in seconds) does it have? 4:52 .1 49 M11 Assembly Line Precedence Diagra

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts