Question: In a face milling operation, the cutting tool has a diameter of ( mathbf { 6 0 ~ m m } )

In a face milling operation, the cutting tool has a diameter of mathbf ~ m m with mathbf tungsten carbide WC inserts and the spindle speed is A rpm Given that the feed rate is mathrm~mmmathrmrev and the life of the cutting edge of each insert is given by Taylor's Tool Life equation VT

Notes: Aunderlinel a s t digit of your student ID A

Determine:

a The time in minutes before each insert needs to be changed to a new edge.

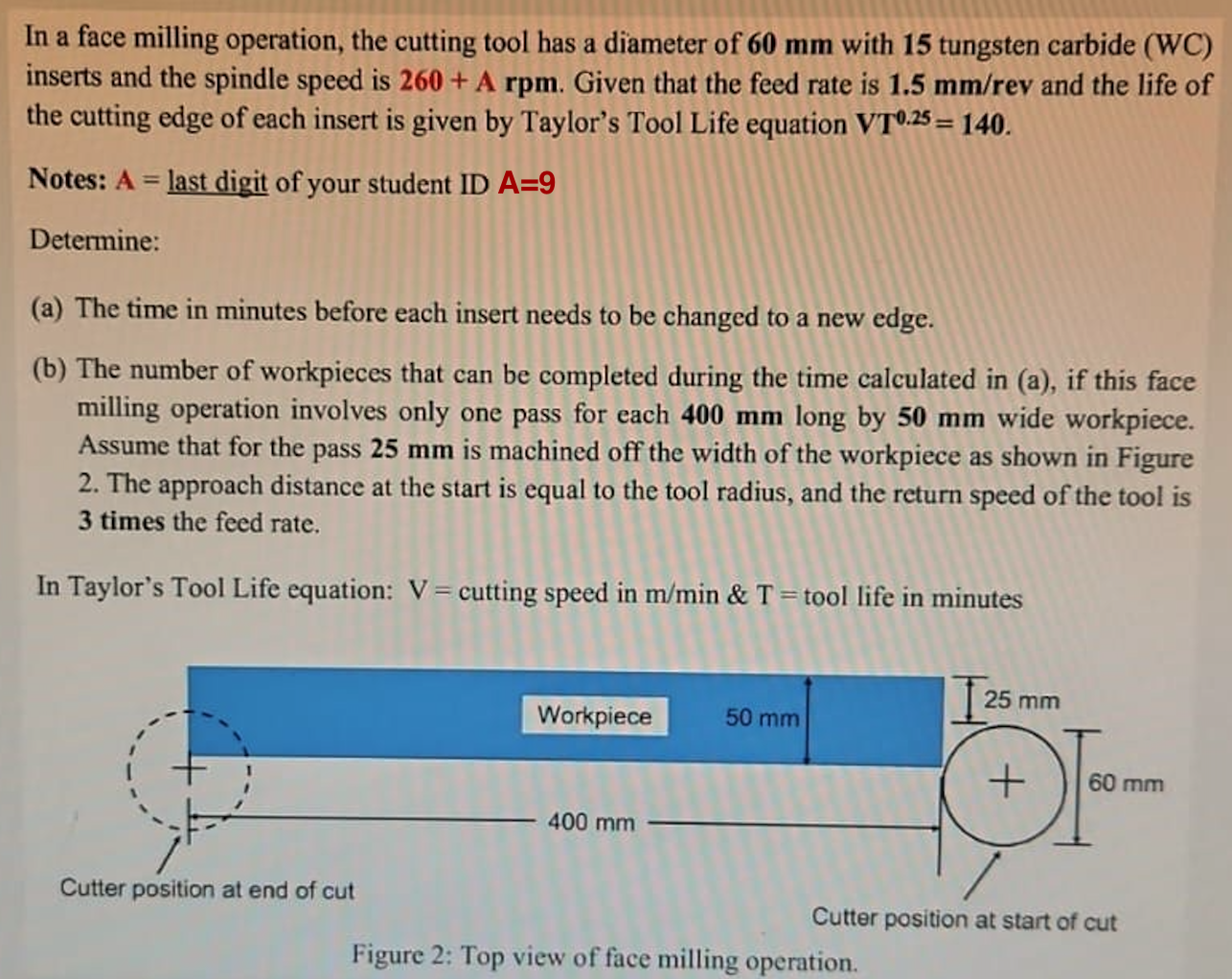

b The number of workpieces that can be completed during the time calculated in a if this face milling operation involves only one pass for each mathbfmathrmmm long by mathbf ~ m m wide workpiece. Assume that for the pass mathbf ~ m m is machined off the width of the workpiece as shown in Figure The approach distance at the start is equal to the tool radius, and the return speed of the tool is times the feed rate.

In Taylor's Tool Life equation: mathrmV cutting speed in mathrmmmathrmmin& mathrm~T tool life in minutes

Figure : Top view of face milling operation.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock