Question: In addition to filling errors, solidification shrinkages, and pores, when inspecting the handles produced in the experiments, team members realised that many of them had

In addition to filling errors, solidification shrinkages, and pores, when inspecting the handles produced in the experiments, team members realised that many of them had structural abnormalities, such as fissures. Structural abnormalities tend to appear when the transition of the alloy from its liquid state to the solid state does not occur properly, which might happen if the mechanical properties of the alloy are jeopardized due to mixing with other types of alloys or because it is contaminated with scoria and impurities. To investigate the influence of alloy mixes

in the quality of the manufactured handles, some samples of defective handles containing structural abnormalities were sent to an accredited laboratory for analysis. The laboratory found high contents of silicon in the holes and fissures of the handles, which is a typical element in other types of alloys, not in the AGZ alloy that used to cast this type of handle. The laboratory report thus confirmed that alloy mixings is a significant cause for the occurrence of structural abnormalities.

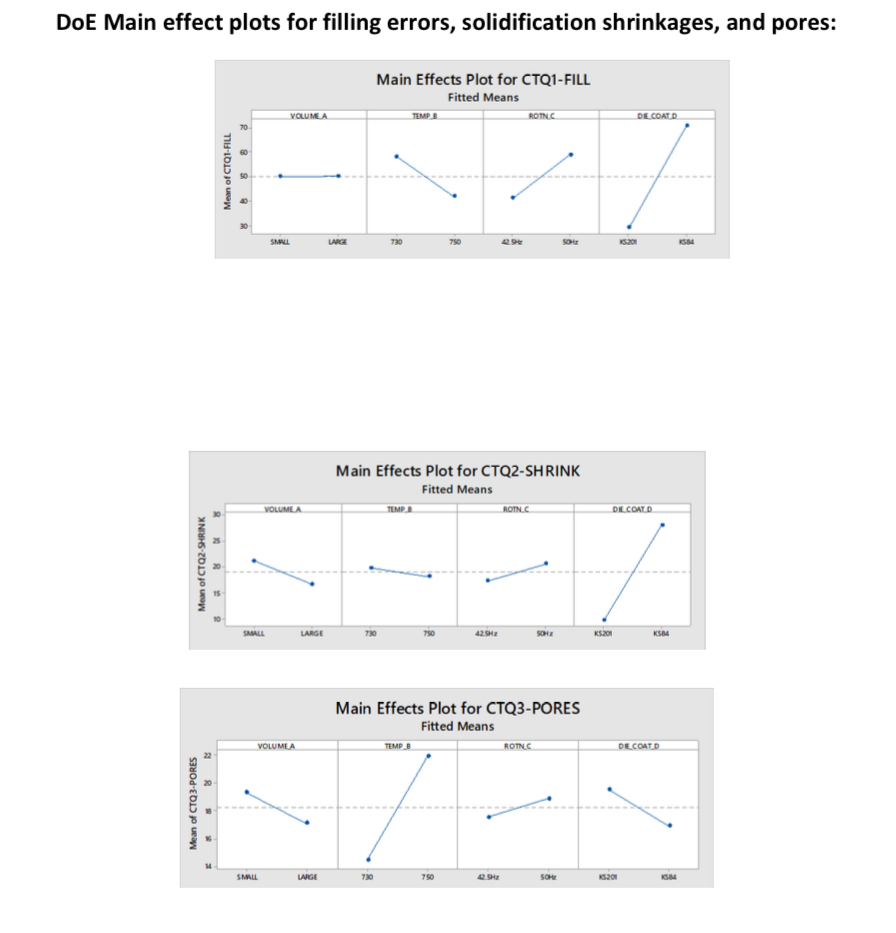

After having determined the root causes for the high rejection rate of the manufactured handles in the previous phase of the DMAIC approach, the project team now needs to consider the development of improvement actions to be implemented. Define critical improvement steps making use of the data that follows. Include a reference on how a control plan may be integrated.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock