Question: In an industrial facility located in Doha, Qatar, two parallel hot and cold pipelines spaced 0.6 m apart are buried in soil. The pipes

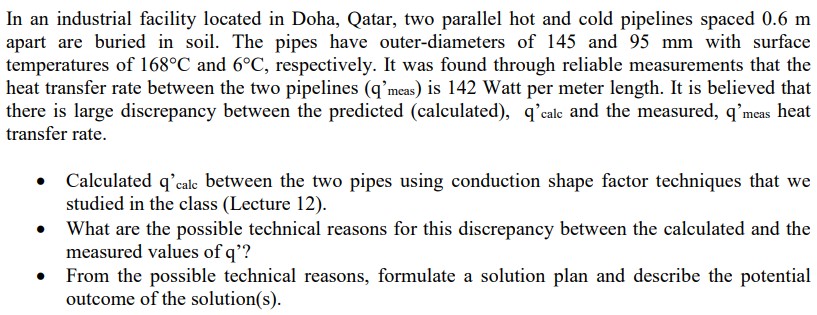

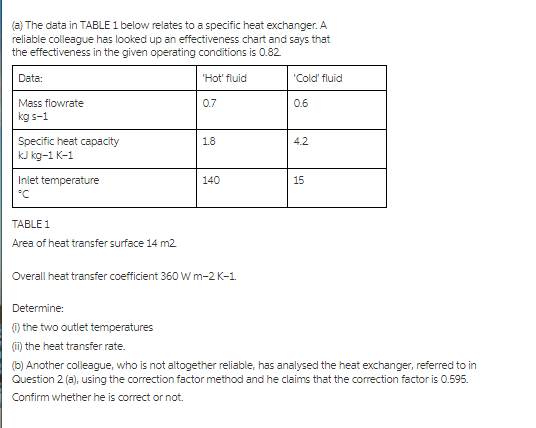

In an industrial facility located in Doha, Qatar, two parallel hot and cold pipelines spaced 0.6 m apart are buried in soil. The pipes have outer-diameters of 145 and 95 mm with surface temperatures of 168C and 6C, respectively. It was found through reliable measurements that the heat transfer rate between the two pipelines (q'meas) is 142 Watt per meter length. It is believed that there is large discrepancy between the predicted (calculated), q'cale and the measured, q'meas heat transfer rate. Calculated q'cale between the two pipes using conduction shape factor techniques that we studied in the class (Lecture 12). What are the possible technical reasons for this discrepancy between the calculated and the measured values of q'? From the possible technical reasons, formulate a solution plan and describe the potential outcome of the solution(s). (a) The data in TABLE 1 below relates to a specific heat exchanger. A reliable colleague has looked up an effectiveness chart and says that the effectiveness in the given operating conditions is 0.82. 'Hot' fluid 0.7 Data: Mass flowrate kg s-1 Specific heat capacity kJ kg-1 K-1 Inlet temperature C TABLE 1 Area of heat transfer surface 14 m2 1.8 Determine: (1) the two outlet temperatures (ii) the heat transfer rate. 140 Overall heat transfer coefficient 360 W m-2 K-1. 'Cold' fluid 0.6 4.2 15 (b) Another colleague, who is not altogether reliable, has analysed the heat exchanger, referred to in Question 2 (a), using the correction factor method and he claims that the correction factor is 0.595. Confirm whether he is correct or not.

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts