Question: In this project, you are tasked with developing a control system for a mixing and filling machine. The machine comprises a DC motor, three

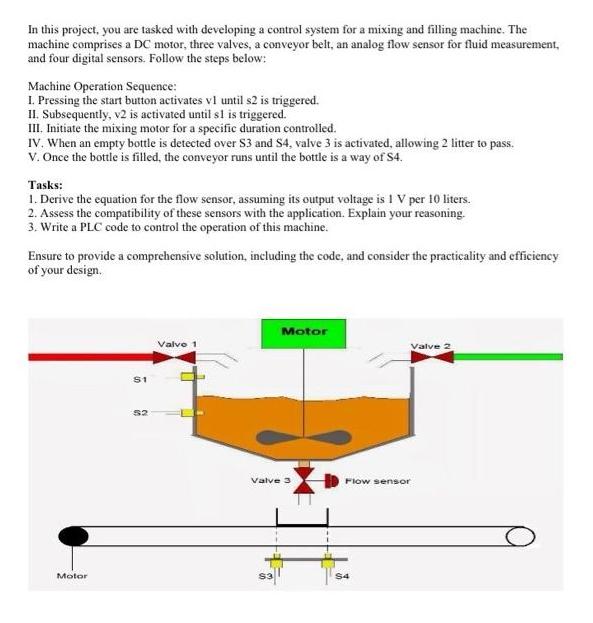

In this project, you are tasked with developing a control system for a mixing and filling machine. The machine comprises a DC motor, three valves, a conveyor belt, an analog flow sensor for fluid measurement, and four digital sensors. Follow the steps below: Machine Operation Sequence: 1. Pressing the start button activates v1 until s2 is triggered. II. Subsequently, v2 is activated until s1 is triggered. III. Initiate the mixing motor for a specific duration controlled. IV. When an empty bottle is detected over $3 and S4, valve 3 is activated, allowing 2 litter to pass. V. Once the bottle is filled, the conveyor runs until the bottle is a way of S4. Tasks: 1. Derive the equation for the flow sensor, assuming its output voltage is 1 V per 10 liters. 2. Assess the compatibility of these sensors with the application. Explain your reasoning. 3. Write a PLC code to control the operation of this machine. Ensure to provide a comprehensive solution, including the code, and consider the practicality and efficiency of your design. Motor S1 $2 Valve 1 Motor Valve 3 Valve 2 Flow sensor S4

Step by Step Solution

3.49 Rating (156 Votes )

There are 3 Steps involved in it

Sure I can help you with the control system for the mixing and filling machine The image y... View full answer

Get step-by-step solutions from verified subject matter experts