Question: Please read the article titled Time to Market a Key In Make or Buy Decisions Download Time to Market a Key In Make or Buy

Please read the article titled Time to Market a Key In Make or Buy Decisions Download Time to Market a Key In Make or Buy Decisions . In at least three bullet-points, discuss the key points of the article.

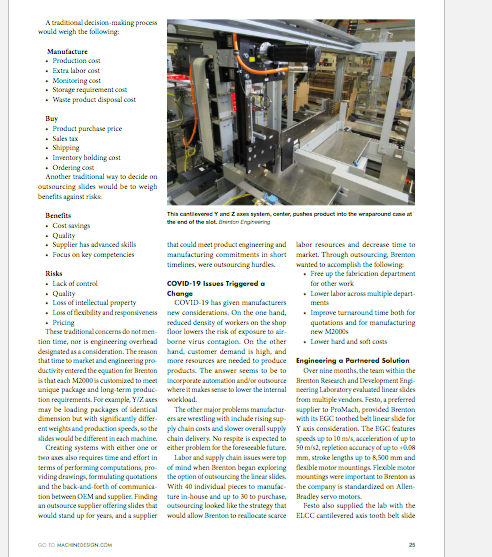

Time to Market a Key In Make or Buy Decisions A Brenton-Festo collaboration finds a faster specification solution. f Brenton Engineering had adhered to Outsourcing Toothed Belt Slides ing cases, a single Yaxis for gluing case traditional outsourcing decision-mak Brenton is one of North America's lead flaps, and cantilevered Y and Z axes for ing the company may have obtained ing case packing and palletiring original tamping down flaps after gluing. These the outsourced component it wanted equipment manufacturers through its Pre slides must be fast, accurate and rigid for but not the one it needed for improving Mach brand, and its M2000 is the com long life and high performance under 24/7 competitiveness. Instead of make-versus pany's top selling side-load case packet. operation. buy calculations based primarily on cost Known for its short installation time and Each slide may have up to 70 different and risk for outsourcing a highly engi- intuitive operation, the M2000 also offers components, 10 of which are manufac- neered component, Brenton added con high OEE through fast, accurate change tured by Brenton. Some of the compo siderations of higher overall engineering over. This 35 case-per-minute unit packs nents are sent out for anodizing, adding and fabrication productivity, along with products in wrap around, knock down time to the manufacturing process. The faster time to market, for both quotations and regular sletted cases, as well as trays high number of linear slides required each on new machines and manufacture of sold M2000 case packers can support up to year, the number of individual parts and units. The results proved advantageous three toothed belt linear slide systems time for assembly made linear slides can across the board. cantilevered Y and Z axes system for load didates for outsourcing. Brenton explored linear axis make versus buy decisions for its top selling M2000 case packer, shown here. Nine months of testing showed buying linear axes for all the right reasons pays off. Brenton Engineering A traditional decision-making proces would weigh the following Manufacture Production cos . Extra labor cost Monitoring cost Storage requirement cost Waste product disposal cost Buy . Product purchase price Sales tax Shipping Inventory holding cost Ordering cost Another traditional way to decide on outsourcing slides would be to weigh benefits against Benefits This conteved Y and Zusate, center, pushes product into the wraparound came at . Cost savings the end of the strong Quality Supplier has advanced skills that could meet product engineering and labor resources and decrease time to . Focus on key competencies manufacturing commitments in short market. Through outsourcing, Brenton timelines, were outsourcing hurdles wanted to accomplish the following Risks Free up the fabrication department . Lack of control COVID-19 Issues Triggered a for other work . Quality Change . Lower labor across multiple depart Loss of intellectual property COVID. 19 has given manufacturers ments Loss of flexibility and responsiveness new considerations. On the one hand, Improve turnaround time both for Pricing reduced density of workers on the shop quotations and for manufacturing These traditional concerns do not men floor lowers the risk of exposure to air new M2009 tion time, nor is engineering overhead borne virus contagion. On the other . Lower hard and soft costs designated as a consideration. The reason hand, customer demand is high, and that time to market and engineering pro more resources are needed to produce Engineering a Partnered Solution ductivity entered the equation for Brenton products. The answer seems to be to Over nine months, the team within the is that each M2000 s customized to meet incorporate automation and outsource Brenton Research and Development Eng unique package and long-term produce where it makes sense to lower the internal neering Laboeatory evaluated linear sides tion requirements. For example, Y/Zaxes workload. from multiple vendors Festo, a preferred may be loading packages of identical The other major peoblems manufactur supplier to Pro Mach, provided Brenton dimension but with significantly differers are wrestling with include rising sup with its EGCtoothed belt linear slide for ent weights and production speeds, so the ply chain costs and slower overall supply Yaxis consideration. The EGC features slides would be different in each machine. chain delivery. No respite is expected to speeds up to 10 m/s, acceleration of up to Creating systems with either one of either problem for the foreseeable future. 50m/s2, epletion accuracy of up to 10.08 two are also requires time and effort in Labor and supply chain issues were top, stroke lengths up to 500 mm and terms of performing computations, pro of mind when Brentoe began exploring flexible motor mountings Flexible motor viding drawings, formulating quotations the option of outsourcing the linee slides mountings were important to Brentonas and the back-and-forth of communica With 40 individual pieces to manufac the company is standardized on Allen tion between CEM and supplier. Finding ture in-house and up to 30 to purchase, Hradley servo motors an outsource supplier offering slides that outsourcing looked like the strategy that Festo also supplied the lab with the would stand up for years, and a supplier would allow Brenton to reallocate scarce ELCC cantilevered axis tooth belt slide GOD MACONDESIGN.COM Specification Solutions for Z axis consideratice. The ELCClea slides Benton booked at the flexibility and for download. This allows designers to tures high rigidity, small moving mass capacity of the supplier to provide many work on the project while the slide is and vertical load capacity of up to 100 diferent configurations of slides relatively manufactured. Applications engineers 2. While nota core product with 24-hour quickly and the complexity of ordering preparing quotes have what they need guaranteed shipping, this side would still custom configured slides Brenton evalua in minutes. have assured availability toes looked into how fast 2D and 3D draw Parameters that need to be entered into Festo also assigned fohn Baner, a packings could be delivered as well as how long Handling Guide Online include: aging end-of-line application engineer, tot took to acquire quotations support Benton personnel during the Heeder was another issue, if a custom Axis type, induding single or mul testing and application stages. slide had to be replaced, the teams looked tiple, belt or screw drive untry or Heenton personnel from many depart at how difficult it would be to order a cantileveret ments visited the research lab during the replacement part. For several suppliers, Actuator orientation, horizontal or Desting process to observe the comparative the time between order and receipt od vertical tests and then provide feedback based on drawings and a quotation were measured Axis information, including tooling their needs. The resto slides proved to in weeks load, peoduct weight, fece required, be superior in terms of product quality Lising Festo Handling Guide Online stroke and repetition accuracy and rigidity to order single and multiple axis slides . Information on dynamics, including takes an average of 20 minutes. The cycle time, dwell, max speed, accel Faster Time to Market, Improved toolely required the engineer to plug eration and deceleration Engineering Productivity in parameters and the software did the Center of mass The research and development enyl rest. No calculations are required of the Environmental factors such as tem neering lab staff then turned their eval engineer. At the end of each Handling perature, particulates and washdown ation to the critically important coesid Guide Online session, the engineer has Motors, drives and controls for Festo erations of time and effort to acquire the quote and 2D and 3D drawings ready or customer supplied units 9 Years Small And Mighty Accurate, Stable and Fast Weight Processing NEW! 230.25 HARDY belts. 100% virgin urethane (no regrind waste) makes stonger, longer tasting Die Dos Machado LONG-LIFE BELTS MOVE HEAVY LOADS When a competitor's belts failed after only nine months service in a large postal distribution center, Dura-Belt's Long-Life HT belts replaced them. Nine years later, HT belts are stills going strong -moving your mail on conveyors that run 24 hours/day, 7 days/week. Even though some postal tubs have soft bottoms and carry overweight loads, IT belts take the punishment and keep the mail moving. Over 12 million are in service on pow. ered-roller conveyor systems. For longer life and heavier loads, try time-tested T (high tension) O-ring belts -- the only ones colored "Post Office Blue" 800-770-2358 614-777-0295 Dura-Belt Fax: 614.771 944 www.durabell.com ve PoweUhofer Hohe Weighthouse plagued will y Potprint. At just 22"tokeo Vitaly one Calor Raden Interve, 29,2 ond maintain Weightest Collected for test weights HARDY PROCESS SOLUTIONS Weighing Solutions for Process Packaging for More Than Years -Sights PC Pulgas + Cold Styles Call to Discuss Your Application Today! 1-800-821-5831 or 1-858-278-2900 http://bit.ly/H162000EM DECEMBER 2001 MACHINE DESIGN Specification Solutions Helore the end of the Handling Guide designing a slide. The implications or wabteam. The demonstration, plus the fact Online demonstration, one Brenton faster design freeing engineers for other that the Festo slides were so robust, wasa Engineer opened a project and began dutics excited the entire management and turning point in the evaluation. Brenton engineers used Handling Guide Online to specify slides that were installed as test cases in a few M2000s. Hrenton selected the festo EGC for the Yaxis and the ELCC for the Z-axis for the three areas on the M2000-caseload ing applying glue to the case flaps and tamping the taps down. Pesto provides the axial motor mount kits for the Rock well servo motors Hy outsourcing the slides, Brenton now handles eight components instead of 70 when assembling and installing slides, significantly decreasing fabrication and assembly time and cost. Due diligence in outsourcing paded for this nine month research and development effort. Heen ton believes that outsourcing done with care and with a view to productivity and A Testo LGC for the Yaxis and the LCC for the Z-axis move the guing system over the asured supply produces significant com caune Flape Breton Engineering petitive advantages Zero Leak Valves Since 1948 Quick tum-a-round on over 100,000 standard and custom designs to meet your needs. REELLE Expect the Best Service Technical Sales and Application Engineering High-touch Customer Service Responsive Operations Interactive Hinge Selection Guide Check, relief, shuttie, lock - Inline and cartridge versions. Power Generation HVAC Systems Medical Equipment Fluid Power Compressed Gases Aerospace and many other industries For product details visit www.kepner.com today! REELL ( /=//// Technology. Quality Service te KEPNER PRODUCTS COMPANY VP. Por 0271 630279.com Download the feelinge Selection Guide to your mobile device DECIDE 31 MACHINE DESIGN 28 Time to Market a Key In Make or Buy Decisions A Brenton-Festo collaboration finds a faster specification solution. f Brenton Engineering had adhered to Outsourcing Toothed Belt Slides ing cases, a single Yaxis for gluing case traditional outsourcing decision-mak Brenton is one of North America's lead flaps, and cantilevered Y and Z axes for ing the company may have obtained ing case packing and palletiring original tamping down flaps after gluing. These the outsourced component it wanted equipment manufacturers through its Pre slides must be fast, accurate and rigid for but not the one it needed for improving Mach brand, and its M2000 is the com long life and high performance under 24/7 competitiveness. Instead of make-versus pany's top selling side-load case packet. operation. buy calculations based primarily on cost Known for its short installation time and Each slide may have up to 70 different and risk for outsourcing a highly engi- intuitive operation, the M2000 also offers components, 10 of which are manufac- neered component, Brenton added con high OEE through fast, accurate change tured by Brenton. Some of the compo siderations of higher overall engineering over. This 35 case-per-minute unit packs nents are sent out for anodizing, adding and fabrication productivity, along with products in wrap around, knock down time to the manufacturing process. The faster time to market, for both quotations and regular sletted cases, as well as trays high number of linear slides required each on new machines and manufacture of sold M2000 case packers can support up to year, the number of individual parts and units. The results proved advantageous three toothed belt linear slide systems time for assembly made linear slides can across the board. cantilevered Y and Z axes system for load didates for outsourcing. Brenton explored linear axis make versus buy decisions for its top selling M2000 case packer, shown here. Nine months of testing showed buying linear axes for all the right reasons pays off. Brenton Engineering A traditional decision-making proces would weigh the following Manufacture Production cos . Extra labor cost Monitoring cost Storage requirement cost Waste product disposal cost Buy . Product purchase price Sales tax Shipping Inventory holding cost Ordering cost Another traditional way to decide on outsourcing slides would be to weigh benefits against Benefits This conteved Y and Zusate, center, pushes product into the wraparound came at . Cost savings the end of the strong Quality Supplier has advanced skills that could meet product engineering and labor resources and decrease time to . Focus on key competencies manufacturing commitments in short market. Through outsourcing, Brenton timelines, were outsourcing hurdles wanted to accomplish the following Risks Free up the fabrication department . Lack of control COVID-19 Issues Triggered a for other work . Quality Change . Lower labor across multiple depart Loss of intellectual property COVID. 19 has given manufacturers ments Loss of flexibility and responsiveness new considerations. On the one hand, Improve turnaround time both for Pricing reduced density of workers on the shop quotations and for manufacturing These traditional concerns do not men floor lowers the risk of exposure to air new M2009 tion time, nor is engineering overhead borne virus contagion. On the other . Lower hard and soft costs designated as a consideration. The reason hand, customer demand is high, and that time to market and engineering pro more resources are needed to produce Engineering a Partnered Solution ductivity entered the equation for Brenton products. The answer seems to be to Over nine months, the team within the is that each M2000 s customized to meet incorporate automation and outsource Brenton Research and Development Eng unique package and long-term produce where it makes sense to lower the internal neering Laboeatory evaluated linear sides tion requirements. For example, Y/Zaxes workload. from multiple vendors Festo, a preferred may be loading packages of identical The other major peoblems manufactur supplier to Pro Mach, provided Brenton dimension but with significantly differers are wrestling with include rising sup with its EGCtoothed belt linear slide for ent weights and production speeds, so the ply chain costs and slower overall supply Yaxis consideration. The EGC features slides would be different in each machine. chain delivery. No respite is expected to speeds up to 10 m/s, acceleration of up to Creating systems with either one of either problem for the foreseeable future. 50m/s2, epletion accuracy of up to 10.08 two are also requires time and effort in Labor and supply chain issues were top, stroke lengths up to 500 mm and terms of performing computations, pro of mind when Brentoe began exploring flexible motor mountings Flexible motor viding drawings, formulating quotations the option of outsourcing the linee slides mountings were important to Brentonas and the back-and-forth of communica With 40 individual pieces to manufac the company is standardized on Allen tion between CEM and supplier. Finding ture in-house and up to 30 to purchase, Hradley servo motors an outsource supplier offering slides that outsourcing looked like the strategy that Festo also supplied the lab with the would stand up for years, and a supplier would allow Brenton to reallocate scarce ELCC cantilevered axis tooth belt slide GOD MACONDESIGN.COM Specification Solutions for Z axis consideratice. The ELCClea slides Benton booked at the flexibility and for download. This allows designers to tures high rigidity, small moving mass capacity of the supplier to provide many work on the project while the slide is and vertical load capacity of up to 100 diferent configurations of slides relatively manufactured. Applications engineers 2. While nota core product with 24-hour quickly and the complexity of ordering preparing quotes have what they need guaranteed shipping, this side would still custom configured slides Brenton evalua in minutes. have assured availability toes looked into how fast 2D and 3D draw Parameters that need to be entered into Festo also assigned fohn Baner, a packings could be delivered as well as how long Handling Guide Online include: aging end-of-line application engineer, tot took to acquire quotations support Benton personnel during the Heeder was another issue, if a custom Axis type, induding single or mul testing and application stages. slide had to be replaced, the teams looked tiple, belt or screw drive untry or Heenton personnel from many depart at how difficult it would be to order a cantileveret ments visited the research lab during the replacement part. For several suppliers, Actuator orientation, horizontal or Desting process to observe the comparative the time between order and receipt od vertical tests and then provide feedback based on drawings and a quotation were measured Axis information, including tooling their needs. The resto slides proved to in weeks load, peoduct weight, fece required, be superior in terms of product quality Lising Festo Handling Guide Online stroke and repetition accuracy and rigidity to order single and multiple axis slides . Information on dynamics, including takes an average of 20 minutes. The cycle time, dwell, max speed, accel Faster Time to Market, Improved toolely required the engineer to plug eration and deceleration Engineering Productivity in parameters and the software did the Center of mass The research and development enyl rest. No calculations are required of the Environmental factors such as tem neering lab staff then turned their eval engineer. At the end of each Handling perature, particulates and washdown ation to the critically important coesid Guide Online session, the engineer has Motors, drives and controls for Festo erations of time and effort to acquire the quote and 2D and 3D drawings ready or customer supplied units 9 Years Small And Mighty Accurate, Stable and Fast Weight Processing NEW! 230.25 HARDY belts. 100% virgin urethane (no regrind waste) makes stonger, longer tasting Die Dos Machado LONG-LIFE BELTS MOVE HEAVY LOADS When a competitor's belts failed after only nine months service in a large postal distribution center, Dura-Belt's Long-Life HT belts replaced them. Nine years later, HT belts are stills going strong -moving your mail on conveyors that run 24 hours/day, 7 days/week. Even though some postal tubs have soft bottoms and carry overweight loads, IT belts take the punishment and keep the mail moving. Over 12 million are in service on pow. ered-roller conveyor systems. For longer life and heavier loads, try time-tested T (high tension) O-ring belts -- the only ones colored "Post Office Blue" 800-770-2358 614-777-0295 Dura-Belt Fax: 614.771 944 www.durabell.com ve PoweUhofer Hohe Weighthouse plagued will y Potprint. At just 22"tokeo Vitaly one Calor Raden Interve, 29,2 ond maintain Weightest Collected for test weights HARDY PROCESS SOLUTIONS Weighing Solutions for Process Packaging for More Than Years -Sights PC Pulgas + Cold Styles Call to Discuss Your Application Today! 1-800-821-5831 or 1-858-278-2900 http://bit.ly/H162000EM DECEMBER 2001 MACHINE DESIGN Specification Solutions Helore the end of the Handling Guide designing a slide. The implications or wabteam. The demonstration, plus the fact Online demonstration, one Brenton faster design freeing engineers for other that the Festo slides were so robust, wasa Engineer opened a project and began dutics excited the entire management and turning point in the evaluation. Brenton engineers used Handling Guide Online to specify slides that were installed as test cases in a few M2000s. Hrenton selected the festo EGC for the Yaxis and the ELCC for the Z-axis for the three areas on the M2000-caseload ing applying glue to the case flaps and tamping the taps down. Pesto provides the axial motor mount kits for the Rock well servo motors Hy outsourcing the slides, Brenton now handles eight components instead of 70 when assembling and installing slides, significantly decreasing fabrication and assembly time and cost. Due diligence in outsourcing paded for this nine month research and development effort. Heen ton believes that outsourcing done with care and with a view to productivity and A Testo LGC for the Yaxis and the LCC for the Z-axis move the guing system over the asured supply produces significant com caune Flape Breton Engineering petitive advantages Zero Leak Valves Since 1948 Quick tum-a-round on over 100,000 standard and custom designs to meet your needs. REELLE Expect the Best Service Technical Sales and Application Engineering High-touch Customer Service Responsive Operations Interactive Hinge Selection Guide Check, relief, shuttie, lock - Inline and cartridge versions. Power Generation HVAC Systems Medical Equipment Fluid Power Compressed Gases Aerospace and many other industries For product details visit www.kepner.com today! REELL ( /=//// Technology. Quality Service te KEPNER PRODUCTS COMPANY VP. Por 0271 630279.com Download the feelinge Selection Guide to your mobile device DECIDE 31 MACHINE DESIGN 28Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock