Question: In this question, why is lambda 4/150*60 ? where does '4' come from? i thought lambda should be 1/150*60, because 150 mins is inter-arrival time.

In this question, why is lambda 4/150*60 ? where does '4' come from? i thought lambda should be 1/150*60, because 150 mins is inter-arrival time.

In this question, why is lambda 4/150*60 ? where does '4' come from? i thought lambda should be 1/150*60, because 150 mins is inter-arrival time.

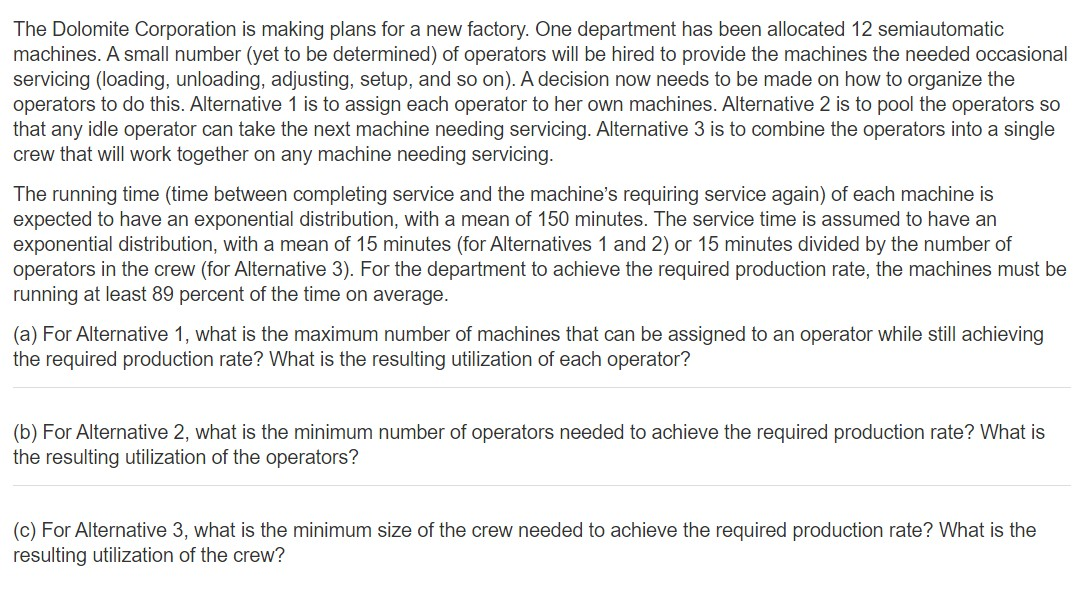

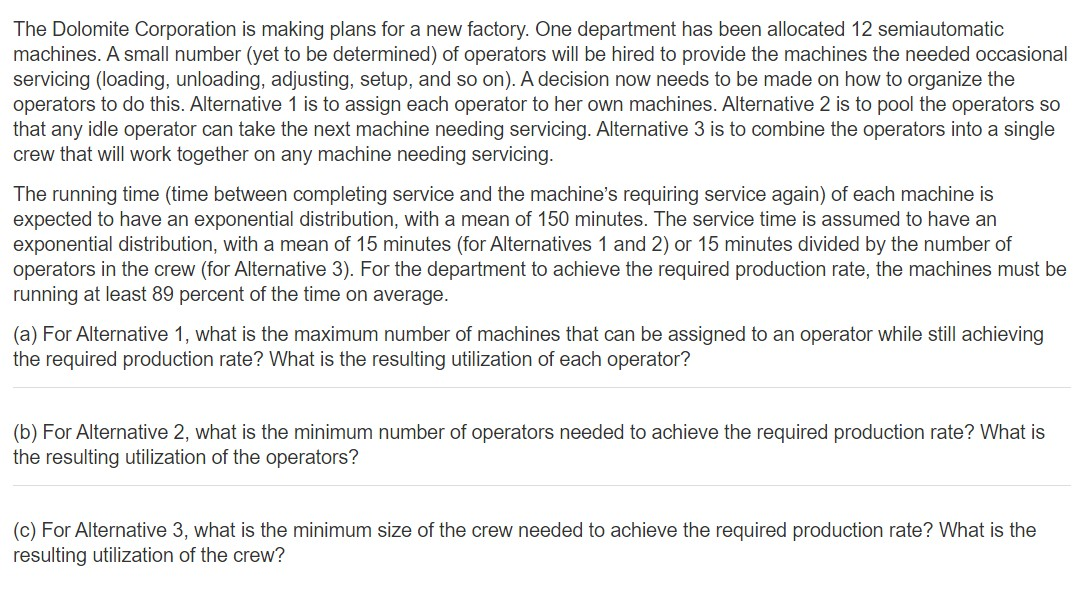

The Dolomite Corporation is making plans for a new factory. One department has been allocated 12 semiautomatic machines. A small number (yet to be determined) of operators will be hired to provide the machines the needed occasional servicing (loading, unloading, adjusting, setup, and so on). A decision now needs to be made on how to organize the operators to do this. Alternative 1 is to assign each operator to her own machines. Alternative 2 is to pool the operators so that any idle operator can take the next machine needing servicing. Alternative 3 is to combine the operators into a single crew that will work together on any machine needing servicing. The running time (time between completing service and the machine's requiring service again) of each machine is expected to have an exponential distribution, with a mean of 150 minutes. The service time is assumed to have an exponential distribution, with a mean of 15 minutes (for Alternatives 1 and 2) or 15 minutes divided by the number of operators in the crew (for Alternative 3). For the department to achieve the required production rate, the machines must be running at least 89 percent of the time on average. (a) For Alternative 1, what is the maximum number of machines that can be assigned to an operator while still achieving the required production rate? What is the resulting utilization of each operator? (b) For Alternative 2, what is the minimum number of operators needed to achieve the required production rate? What is the resulting utilization of the operators? (c) For Alternative 3, what is the minimum size of the crew needed to achieve the required production rate? What is the resulting utilization of the crew? The Dolomite Corporation is making plans for a new factory. One department has been allocated 12 semiautomatic machines. A small number (yet to be determined) of operators will be hired to provide the machines the needed occasional servicing (loading, unloading, adjusting, setup, and so on). A decision now needs to be made on how to organize the operators to do this. Alternative 1 is to assign each operator to her own machines. Alternative 2 is to pool the operators so that any idle operator can take the next machine needing servicing. Alternative 3 is to combine the operators into a single crew that will work together on any machine needing servicing. The running time (time between completing service and the machine's requiring service again) of each machine is expected to have an exponential distribution, with a mean of 150 minutes. The service time is assumed to have an exponential distribution, with a mean of 15 minutes (for Alternatives 1 and 2) or 15 minutes divided by the number of operators in the crew (for Alternative 3). For the department to achieve the required production rate, the machines must be running at least 89 percent of the time on average. (a) For Alternative 1, what is the maximum number of machines that can be assigned to an operator while still achieving the required production rate? What is the resulting utilization of each operator? (b) For Alternative 2, what is the minimum number of operators needed to achieve the required production rate? What is the resulting utilization of the operators? (c) For Alternative 3, what is the minimum size of the crew needed to achieve the required production rate? What is the resulting utilization of the crew

In this question, why is lambda 4/150*60 ? where does '4' come from? i thought lambda should be 1/150*60, because 150 mins is inter-arrival time.

In this question, why is lambda 4/150*60 ? where does '4' come from? i thought lambda should be 1/150*60, because 150 mins is inter-arrival time.