Question: Inspection Cost-Benefit: Note: This question does not correspond directly to a situation presented in the Lecture Materials / Media, but could be considered a part

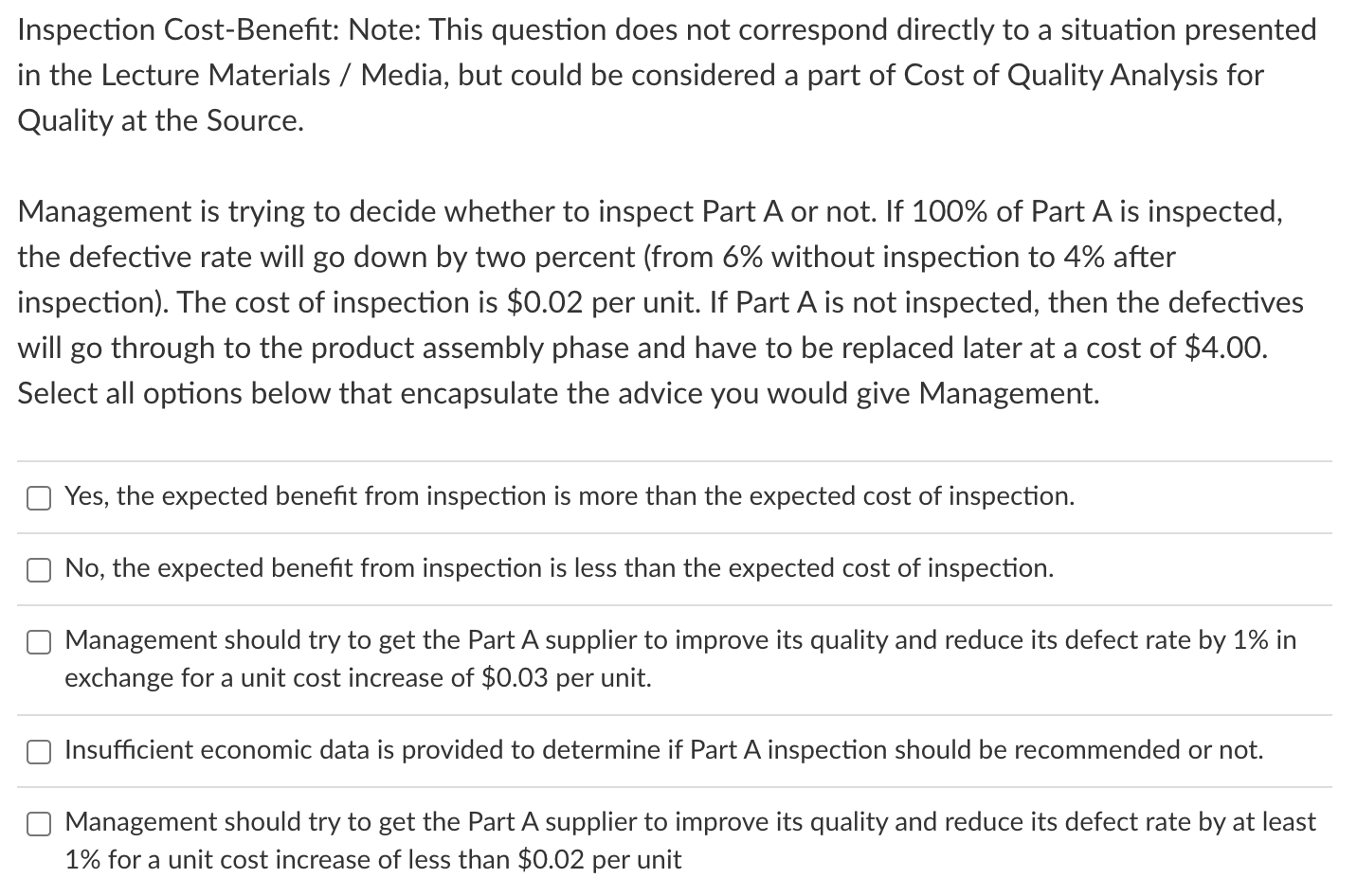

Inspection Cost-Benefit: Note: This question does not correspond directly to a situation presented in the Lecture Materials / Media, but could be considered a part of Cost of Quality Analysis for Quality at the Source. Management is trying to decide whether to inspect Part A or not. If 100% of Part A is inspected, the defective rate will go down by two percent (from 6% without inspection to 4% after inspection). The cost of inspection is $0.02 per unit. If Part A is not inspected, then the defectives will go through to the product assembly phase and have to be replaced later at a cost of $4.00. Select all options below that encapsulate the advice you would give Management. Yes, the expected benefit from inspection is more than the expected cost of inspection. No, the expected benefit from inspection is less than the expected cost of inspection. Management should try to get the Part A supplier to improve its quality and reduce its defect rate by 1% in exchange for a unit cost increase of $0.03 per unit. Insufficient economic data is provided to determine if Part A inspection should be recommended or not. Management should try to get the Part A supplier to improve its quality and reduce its defect rate by at least 1% for a unit cost increase of less than $0.02 per unit

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts