Question: Instructions The main tool this week is Material Requirements Planning (MRP). PIMS, Inc., has been manufacturing plumbing equipment since 1999. Because of the depressed economic

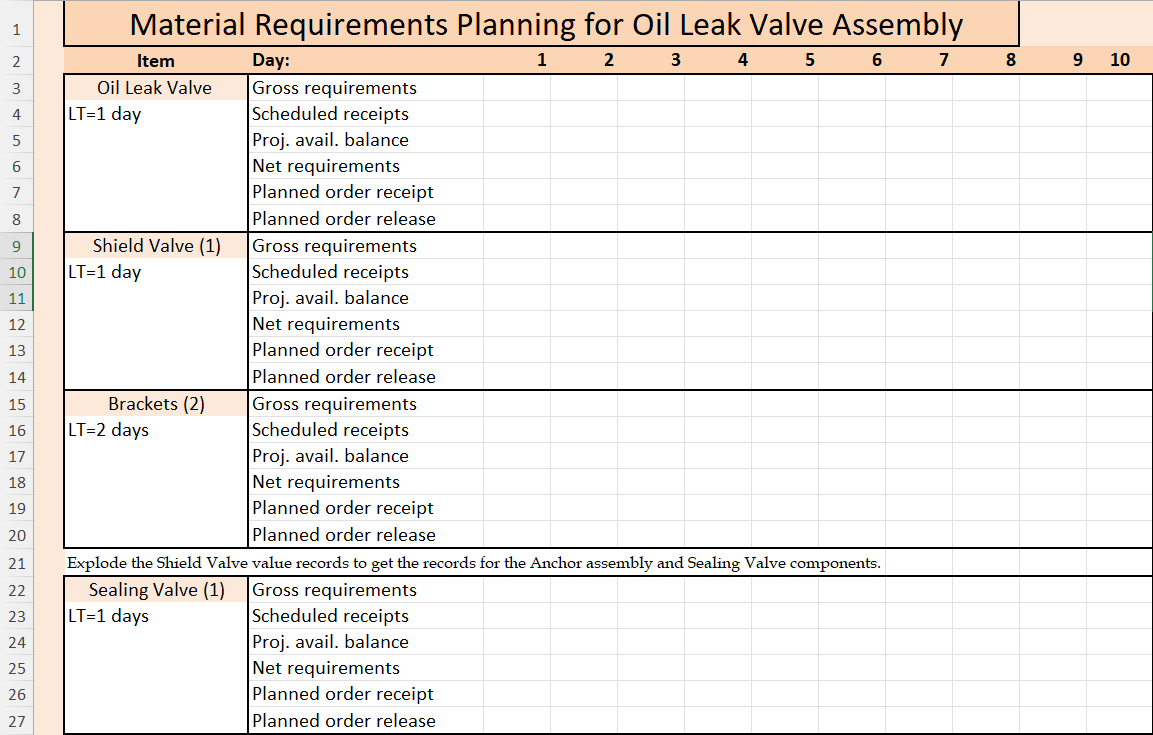

Instructions The main tool this week is Material Requirements Planning (MRP). PIMS, Inc., has been manufacturing plumbing equipment since 1999. Because of the depressed economic conditions, component parts are assembled in batch runs. At any given time, each level of production has several partially assembled components. Given the following assembly and inventory information, construct a product structure diagram for the oil leak valve, and plan the order releases necessary to assemble 400 oil leak valves for period 10. Description of the Production Process Production of the valve begins with the base. The base is placed and secured in a housing. Ball bearings are then installed on opposing sides of the base housing. The rear base cover is fitted on and held while the front cover is secured with U-bolts. Next, the anchor assembly is connected. Finally, two sets of brackets are screwed on and the oil leak valve is checked before shipping. Assume the use of the multiple of fixed lot sizes technique.

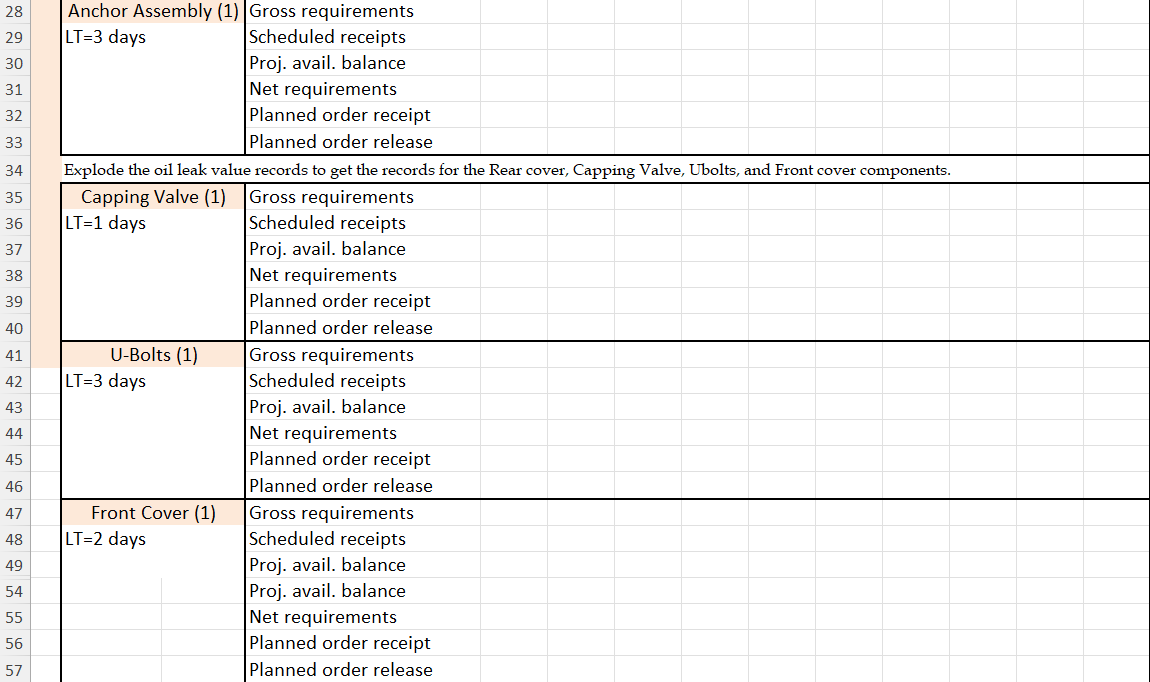

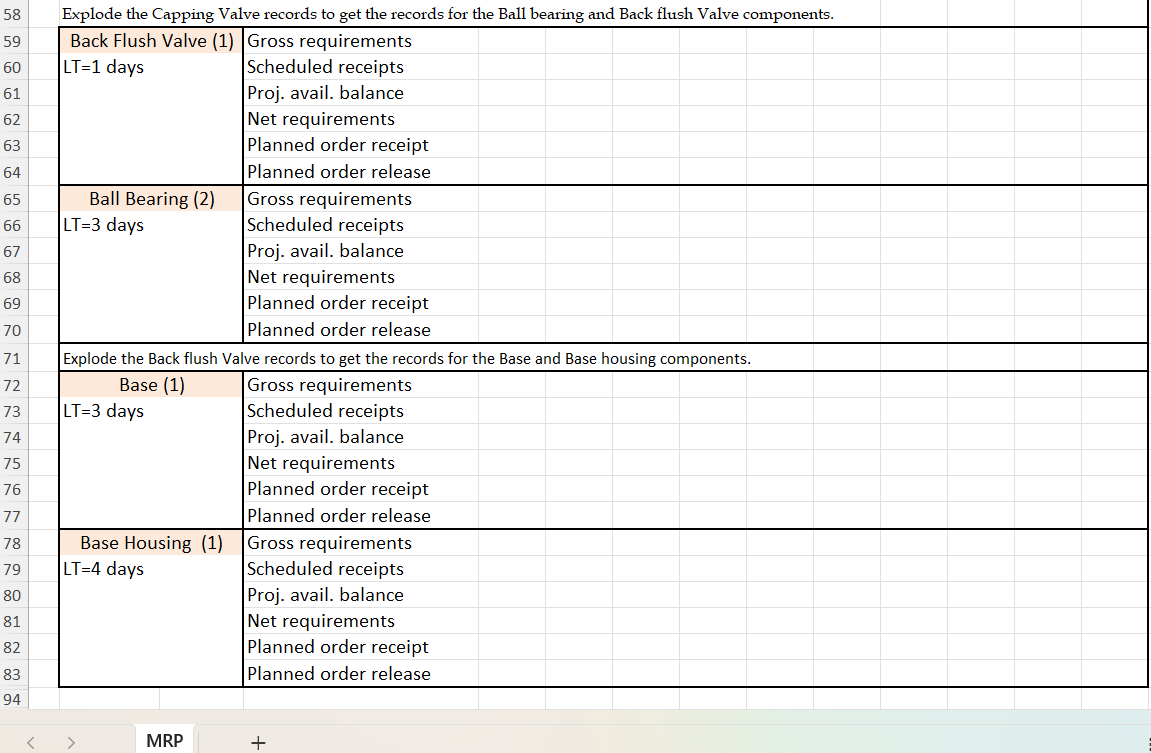

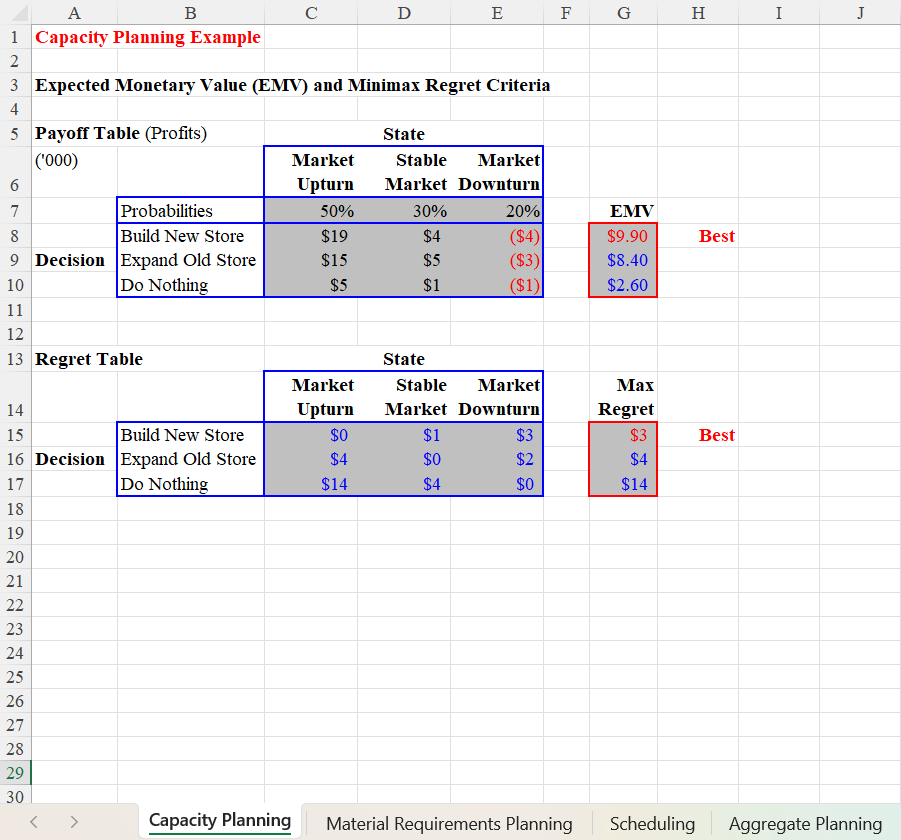

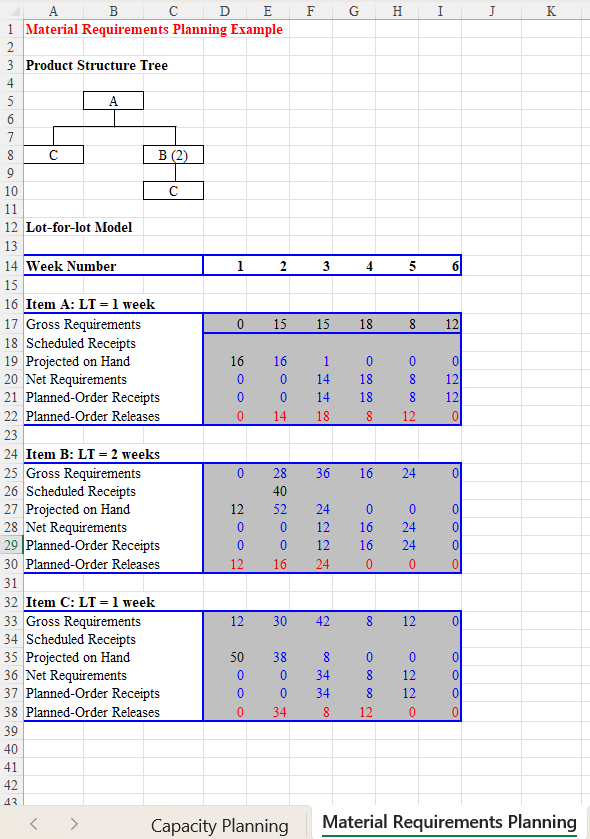

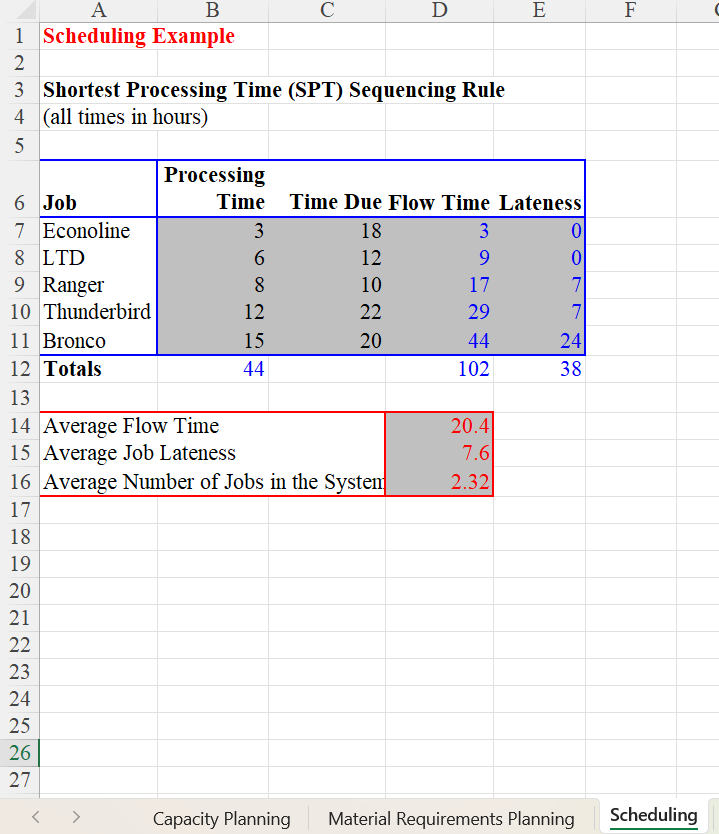

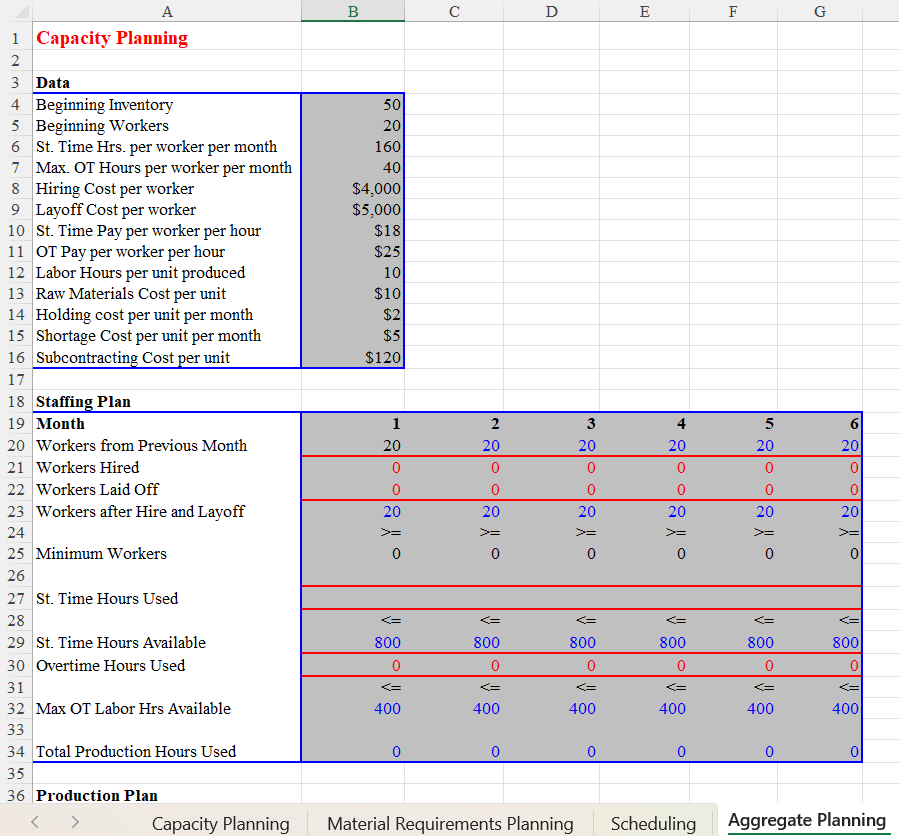

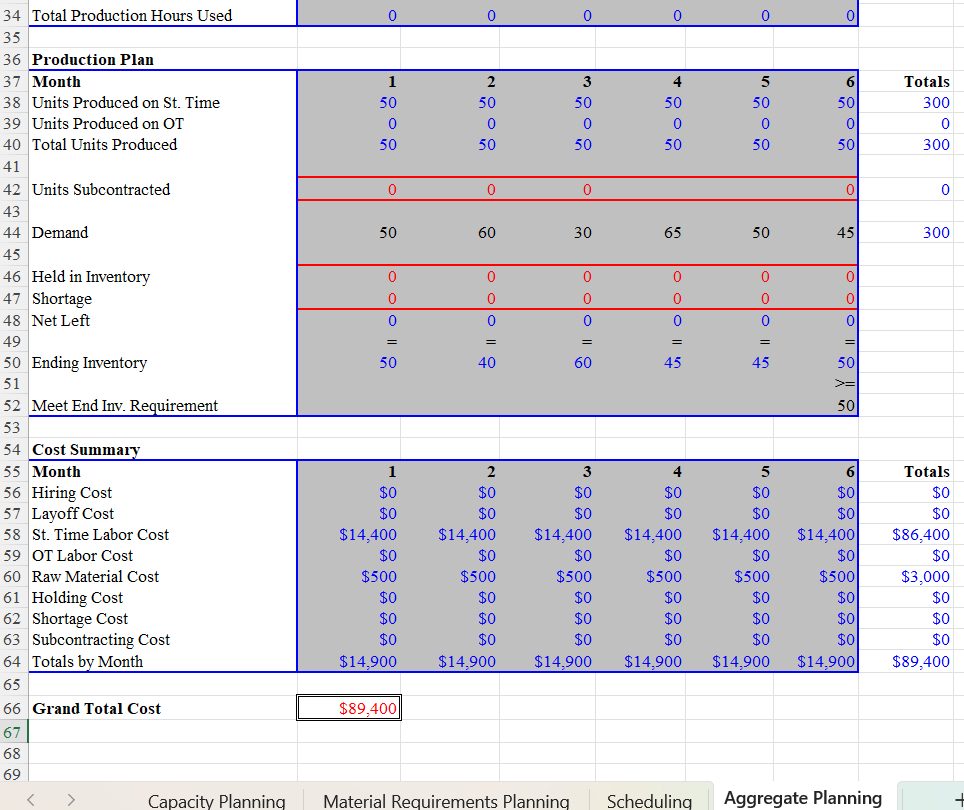

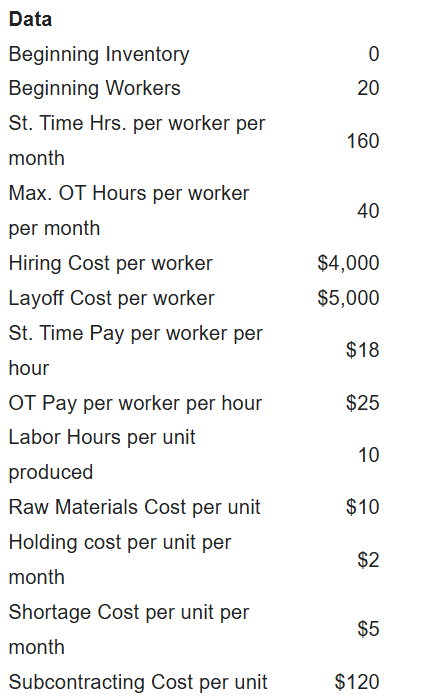

= W o ~ s W M | Material Requirements Planning for Oil Leak Valve Assembly | Item Qil Leak Valve LT=1 day Shield Valve (1) LT=1 day Brackets (2) LT=2 days Day: 1 2 3 4 5 6 Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planned order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planned order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planned order release Explode the Shield Valve value records to get the records for the Anchor assembly and Sealing Valve components. Sealing Valve (1) LT=1 days Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planned order release 7 8 10 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 54 55 56 57 Anchor Assembly (1) LT=3 days Explode the oil leak value records to get the records for the Rear cover, Capping Valve, Ubolts, and Front cover components. Capping Valve (1) LT=1 days U-Bolts (1) LT=3 days Front Cover (1) LT=2 days Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planned order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planned order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planned order release Gross requirements Scheduled receipts Proj. avail. balance Proj. avail. balance Net requirements Planned order receipt Planned order release 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 94 Explode the Capping Valve records to get the records for the Ball bearing and Back flush Valve components. Back Flush Valve (1) LT=1 days Ball Bearing (2) LT=3 days Explode the Back flush Valve records to get the records for the Base and Base housing components. Gross requirements Scheduled receipts Proj. avail. balance Base Housing (1) LT=4 days MRP Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planned order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planned order release Net requirements Planned order receipt Planned order release Gross requirements Scheduled receipts Proj. avail. balance Net requirements Planned order receipt Planned order release A B C D E 1 |Capacity Planning Example 2 3 Expected Monetary Value (EMV) and Minimax Regret Criteria 4 5 Payoff Table (Profits) State ('000) Market Stable Market 6 Upturn Market Downturn 7 30% 8 Build New Store $4 9 Decision |Expand Old Store 10 Do Nothing 11 12 13 |Regret Table State Market Stable Market 14 Upturn Market Downturn 15 Build New Store 16 Decision [Expand Old Store 17 Do Nothing 18 19 20 21 22 23 24 25 26 27 28 29 30 Capacity Planning Material Requirements Planning EMV $9.90 Best $8.40 $2.60 $3 Best Scheduling Aggregate Planning A B C D E F G H I J K Material Requirements Planning Example WN Product Structure Tree A C B (2) C Lot-for-lot Model 14 Week Number 1 2 3 4 5 6 15 16 Item A: LT = 1 week 17 Gross Requirements 0 15 15 18 8 12 18 Scheduled Receipts 19 Projected on Hand 16 16 20 Net Requirements 0 14 18 121 21 Planned-Order Receipts 0 14 18 12 22 Planned-Order Releases 14 18 8 12 23 24 Item B: LT = 2 weeks 25 Gross Requirements 0 28 36 16 24 0 26 Scheduled Receipts 40 27 Projected on Hand 12 52 24 O O 28 Net Requirements 0 0 12 16 24 29 Planned-Order Receipts 0 0 12 16 24 30 Planned-Order Releases 12 16 24 0 0 31 32 Item C: LT = 1 week 33 Gross Requirements 12 30 42 12 O 34 Scheduled Receipts 35 Projected on Hand 50 36 Net Requirements 34 12 37 Planned-Order Receipts O 0 12 38 Planned-Order Releases 34 12 39 40 41 42 Capacity Planning Material Requirements PlanningA B C D E F Scheduling Example W No Shortest Processing Time (SPT) Sequencing Rule 4 (all times in hours) 5 Processing 6 Job Time Time Due Flow Time Lateness 7 Econoline 3 18 C 8 LTD 6 12 9 Ranger 8 10 17 10 Thunderbird 12 22 29 11 Bronco 15 20 44 24 12 Totals 44 102 38 13 14 Average Flow Time 20.4 15 Average Job Lateness 7.6 16 Average Number of Jobs in the System 2.32 17 18 19 20 21 22 23 24 25 26 27 Capacity Planning Material Requirements Planning SchedulingA B C D E F G Capacity Planning Data Beginning Inventory 50 Beginning Workers 20 St. Time Hrs. per worker per month 160 Max. OT Hours per worker per month 40 Hiring Cost per worker $4,000 Layoff Cost per worker $5,000 10 St. Time Pay per worker per hour $18 11 OT Pay per worker per hour $25 12 Labor Hours per unit produced 10 13 Raw Materials Cost per unit $10 14 Holding cost per unit per month $2 15 Shortage Cost per unit per month $5 16 Subcontracting Cost per unit $120 17 18 Staffing Plan 19 Month 1 N 3 5 20 Workers from Previous Month 20 20 20 20 20 20 21 Workers Hired 0 22 Workers Laid Off 0 23 Workers after Hire and Layoff 20 20 20 20 20 20 24 > = 2 = 2 = 25 Minimum Workers 0 0 0 0 0 26 St. Time Hours Used 28 Capacity Planning | Material Requirements Planning | Scheduling | Aggregate Planning | Data Beginning Inventory Beginning Workers St. Time Hrs. per worker per month Max. OT Hours per worker per month Hiring Cost per worker Layoff Cost per worker St. Time Pay per worker per hour OT Pay per worker per hour Labor Hours per unit produced Raw Materials Cost per unit Holding cost per unit per month Shortage Cost per unit per month Subcontracting Cost per unit 20 160 40 $4,000 $5,000 $18 $25 10 $10 $2 $5 $120

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts