Question: Inventory Models Question 23 (3 points) An operations manager at an apple sauce processing plant must determine lot size for the Gala unsweetened sauce that

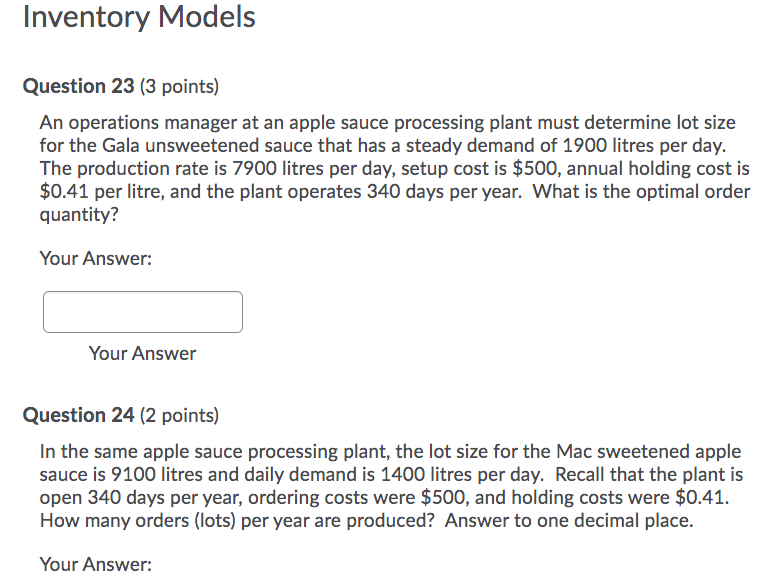

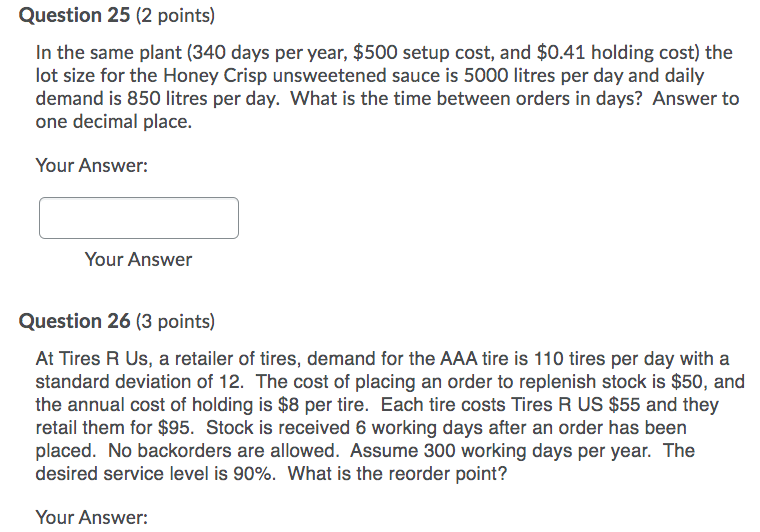

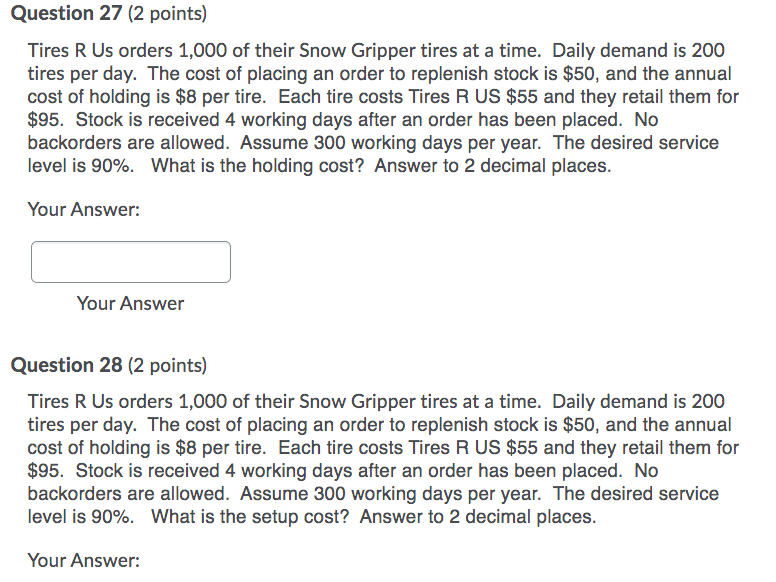

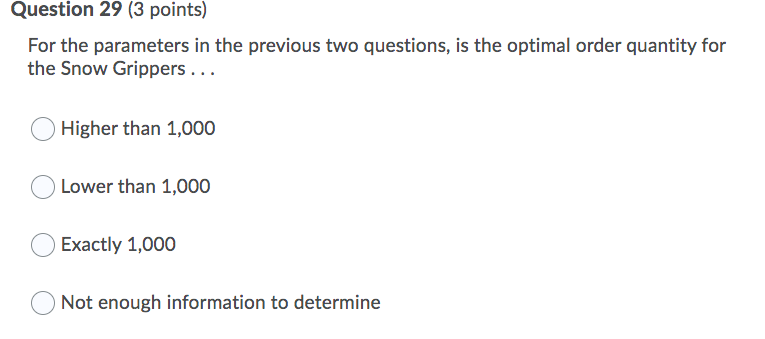

Inventory Models Question 23 (3 points) An operations manager at an apple sauce processing plant must determine lot size for the Gala unsweetened sauce that has a steady demand of 1900 litres per day. The production rate is 7900 litres per day, setup cost is $500, annual holding cost is $0.41 per litre, and the plant operates 340 days per year. What is the optimal order quantity? Your Answer: Your Answer Question 24 (2 points) In the same apple sauce processing plant, the lot size for the Mac sweetened apple sauce is 9100 litres and daily demand is 1400 litres per day. Recall that the plant is open 340 days per year, ordering costs were $500, and holding costs were $0.41. How many orders (lots) per year are produced? Answer to one decimal place. Your Answer: Question 25 (2 points) In the same plant (340 days per year, $500 setup cost, and $0.41 holding cost) the lot size for the Honey Crisp unsweetened sauce is 5000 litres per day and daily demand is 850 litres per day. What is the time between orders in days? Answer to one decimal place. Your Answer: Your Answer Question 26 (3 points) At Tires R Us, a retailer of tires, demand for the AAA tire is 110 tires per day with a standard deviation of 12. The cost of placing an order to replenish stock is $50, and the annual cost of holding is $8 per tire. Each tire costs Tires R US $55 and they retail them for $95. Stock is received 6 working days after an order has been placed. No backorders are allowed. Assume 300 working days per year. The desired service level is 90%. What is the reorder point? Your Answer: Question 27 (2 points) Tires R Us orders 1,000 of their Snow Gripper tires at a time. Daily demand is 200 tires per day. The cost of placing an order to replenish stock is $50, and the annual cost of holding is $8 per tire. Each tire costs Tires R US $55 and they retail them for $95. Stock is received 4 working days after an order has been placed. No backorders are allowed. Assume 300 working days per year. The desired service level is 90%. What is the holding cost? Answer to 2 decimal places. Your Answer: Your Answer Question 28 (2 points) Tires R Us orders 1,000 of their Snow Gripper tires at a time. Daily demand is 200 tires per day. The cost of placing an order to replenish stock is $50, and the annual cost of holding is $8 per tire. Each tire costs Tires R US $55 and they retail them for $95. Stock is received 4 working days after an order has been placed. No backorders are allowed. Assume 300 working days per year. The desired service level is 90%. What is the setup cost? Answer to 2 decimal places. Your Answer: Question 29 (3 points) For the parameters in the previous two questions, is the optimal order quantity for the Snow Grippers ... Higher than 1,000 Lower than 1,000 Exactly 1,000 Not enough information to determine