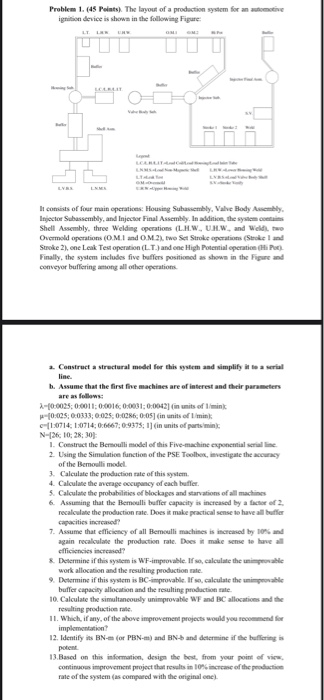

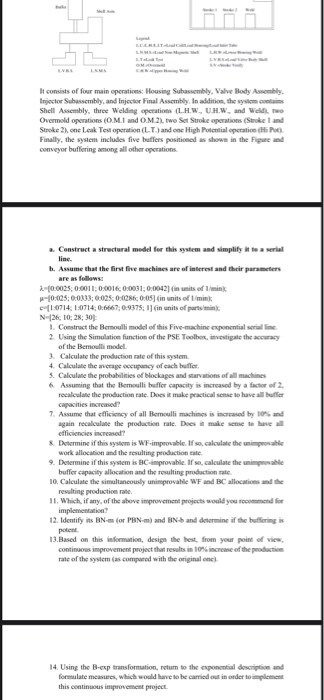

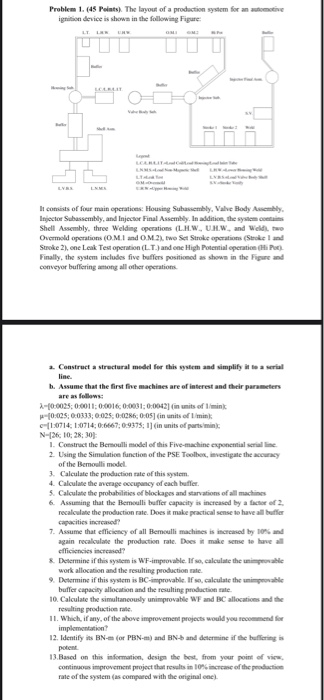

Question: it is one question Problem 1. (45 Points). The layout of a production system for an automotive ignition device is shown in the following Figure

it is one question

Problem 1. (45 Points). The layout of a production system for an automotive ignition device is shown in the following Figure It consists of four main operations: Housing Subassembly, Valve Body Ansembly. Injector Subassembly, and Injector Final Assembly. In addition, the system contains Shell Assembly, three Welding operations (L.HW. UW. and Weld two Overmold operations (O.M.I and O.M.2), two Set Stroke operations (Stroke land Stroke 2), one Leak Test operation (LT.) and one High Potential operation (IP) Finally, the system includes five buffers positioned as shown in the Figure and conveyor buffering among all other operations 2. Construct a structural model for this system and simplify it to a serial line. . Assume that the first five machines are of interest and their parameters are as follows: 2-10:0025;0.0011;0.0016 0.0031:0:0042] (in units of t/min -0.025 0.0333;0.025 0.0086, 0.05] (in units of limin 1:0714, 1:0714.06667; 0.9375; 1)(in units of parts in N-26 10:28:30) 1. Construct the Bemoulli model of this Five-machine exponential seriale 2. Using the Simulation function of the PSE Toolbes, investigate the accuracy of the Bemoulli model 3. Calculate the production rate of this system, 4. Calculate the average occupancy of each buffer 5. Calculate the probabilities of blockages and starvations of all machines 6. Assuming that the Bemoulli buffer capacity is increased by a factor of 2. recalculate the production rate. Does it make practical sense to have all buffer capacities increased 7. Assume that efficiency of all Bemoulli machines is increased by 10% again recalculate the production rate. Does it make sense to have all efficiencies increased & Determine if this system is WF-improvable. If so, calculate the unimpovable work allocation and the resulting production rate. 9. Determine if this system is BC-omprovable. If so, calculate the impoble buffer capacity allocation and the resulting production rate. 10. Calculate the simultaneously unimprovable WF and BC allocations and the resulting production rate 11. Which, if my of the above improvement projects would you recommend for implementation 12. Identify in BN--. (or PBN-m) and BN band determine if the buffering is potent 13. Based on this information, design the best from your point of view. continuous improvement project that results in 10% increase of the production rate of the system (as compared with the original one). It consists of four main operations Housing Subassembly, Valve Body Assembly Injector Subassembly, and Injector Final Assembly. In addition, the system.com Shell Assembly, three Welding operations (L.HW.U.HW. and Well, two Overmold operations (O.M.I and O.M.2), two Set Stroke operations (Stroke land Stroke 2).onc Leak Test operation (LT.) and onc High Potential operation (Pol) Finally, the system includes five buffers positioned as shown in the Figure and conveyor buffering among all other operations 2. Construct a structural model for this system and simplfy it to a serial line. 1. Assume that the first five machines are of interest and their parameters are as follows: -0.0025 0.0011;0.0016, 0.0031:0.0042] (in units of limin -10:005:0:0333;0-025, 0.0086,0.05] (in units of link C-11:0714, 1:0714.06667,09375: 1] (in units of parts min) N-26 10:28:30 1. Construct the Bernoulli model of this Five-machine exponential serial line 2. Using the Simulation function of the PSE Toolbes, investigate the way of the Bemoulli model 3. Calculate the production rate of this system 4. Calculate the average occupancy of each buffet 5. Calculate the probabilities of blockages and starvations of all machines 6 Assuming that the moulli buffer capacity is increased by a factor of 2. recalculate the production rate. Does it make practical sense to have all buffer capacities increased 7. Assume that efficiency of all Bemoulli machines is increased by 10% and again recalculate the production rate. Docsit make sense to have efficiencies increased 8. Determine if this system is WF-improvable. If so, calculate the imperable work allocation and the resulting productionale 9. Determine if this system is BC-improvable. If so, calculate the imposable buffor capacity allocation and the resulting production rate. 10. Calculate the simultaneously unimprovable WF and BC allocations and the resulting productie rate 11. Which, if any of the above improvement projects would you recommend for implementation 12. Identify its BN-m (or PBN-m) and BN and determine if the buffering is 13. Based on this information, design the best from your point of view, continuous improvement project that results in 10% increase of the productie rate of the system (as compared with the original one) 14. Using the B-exp transformation, return to the exponential description and formulate measures, which would have to be carried out in order to implement this continuous improvement project Problem 1. (45 Points). The layout of a production system for an automotive ignition device is shown in the following Figure It consists of four main operations: Housing Subassembly, Valve Body Ansembly. Injector Subassembly, and Injector Final Assembly. In addition, the system contains Shell Assembly, three Welding operations (L.HW. UW. and Weld two Overmold operations (O.M.I and O.M.2), two Set Stroke operations (Stroke land Stroke 2), one Leak Test operation (LT.) and one High Potential operation (IP) Finally, the system includes five buffers positioned as shown in the Figure and conveyor buffering among all other operations 2. Construct a structural model for this system and simplify it to a serial line. . Assume that the first five machines are of interest and their parameters are as follows: 2-10:0025;0.0011;0.0016 0.0031:0:0042] (in units of t/min -0.025 0.0333;0.025 0.0086, 0.05] (in units of limin 1:0714, 1:0714.06667; 0.9375; 1)(in units of parts in N-26 10:28:30) 1. Construct the Bemoulli model of this Five-machine exponential seriale 2. Using the Simulation function of the PSE Toolbes, investigate the accuracy of the Bemoulli model 3. Calculate the production rate of this system, 4. Calculate the average occupancy of each buffer 5. Calculate the probabilities of blockages and starvations of all machines 6. Assuming that the Bemoulli buffer capacity is increased by a factor of 2. recalculate the production rate. Does it make practical sense to have all buffer capacities increased 7. Assume that efficiency of all Bemoulli machines is increased by 10% again recalculate the production rate. Does it make sense to have all efficiencies increased & Determine if this system is WF-improvable. If so, calculate the unimpovable work allocation and the resulting production rate. 9. Determine if this system is BC-omprovable. If so, calculate the impoble buffer capacity allocation and the resulting production rate. 10. Calculate the simultaneously unimprovable WF and BC allocations and the resulting production rate 11. Which, if my of the above improvement projects would you recommend for implementation 12. Identify in BN--. (or PBN-m) and BN band determine if the buffering is potent 13. Based on this information, design the best from your point of view. continuous improvement project that results in 10% increase of the production rate of the system (as compared with the original one). Problem 1. (45 Points). The layout of a production system for an automotive ignition device is shown in the following Figure It consists of four main operations: Housing Subassembly, Valve Body Ansembly. Injector Subassembly, and Injector Final Assembly. In addition, the system contains Shell Assembly, three Welding operations (L.HW. UW. and Weld two Overmold operations (O.M.I and O.M.2), two Set Stroke operations (Stroke land Stroke 2), one Leak Test operation (LT.) and one High Potential operation (IP) Finally, the system includes five buffers positioned as shown in the Figure and conveyor buffering among all other operations 2. Construct a structural model for this system and simplify it to a serial line. . Assume that the first five machines are of interest and their parameters are as follows: 2-10:0025;0.0011;0.0016 0.0031:0:0042] (in units of t/min -0.025 0.0333;0.025 0.0086, 0.05] (in units of limin 1:0714, 1:0714.06667; 0.9375; 1)(in units of parts in N-26 10:28:30) 1. Construct the Bemoulli model of this Five-machine exponential seriale 2. Using the Simulation function of the PSE Toolbes, investigate the accuracy of the Bemoulli model 3. Calculate the production rate of this system, 4. Calculate the average occupancy of each buffer 5. Calculate the probabilities of blockages and starvations of all machines 6. Assuming that the Bemoulli buffer capacity is increased by a factor of 2. recalculate the production rate. Does it make practical sense to have all buffer capacities increased 7. Assume that efficiency of all Bemoulli machines is increased by 10% again recalculate the production rate. Does it make sense to have all efficiencies increased & Determine if this system is WF-improvable. If so, calculate the unimpovable work allocation and the resulting production rate. 9. Determine if this system is BC-omprovable. If so, calculate the impoble buffer capacity allocation and the resulting production rate. 10. Calculate the simultaneously unimprovable WF and BC allocations and the resulting production rate 11. Which, if my of the above improvement projects would you recommend for implementation 12. Identify in BN--. (or PBN-m) and BN band determine if the buffering is potent 13. Based on this information, design the best from your point of view. continuous improvement project that results in 10% increase of the production rate of the system (as compared with the original one). It consists of four main operations Housing Subassembly, Valve Body Assembly Injector Subassembly, and Injector Final Assembly. In addition, the system.com Shell Assembly, three Welding operations (L.HW.U.HW. and Well, two Overmold operations (O.M.I and O.M.2), two Set Stroke operations (Stroke land Stroke 2).onc Leak Test operation (LT.) and onc High Potential operation (Pol) Finally, the system includes five buffers positioned as shown in the Figure and conveyor buffering among all other operations 2. Construct a structural model for this system and simplfy it to a serial line. 1. Assume that the first five machines are of interest and their parameters are as follows: -0.0025 0.0011;0.0016, 0.0031:0.0042] (in units of limin -10:005:0:0333;0-025, 0.0086,0.05] (in units of link C-11:0714, 1:0714.06667,09375: 1] (in units of parts min) N-26 10:28:30 1. Construct the Bernoulli model of this Five-machine exponential serial line 2. Using the Simulation function of the PSE Toolbes, investigate the way of the Bemoulli model 3. Calculate the production rate of this system 4. Calculate the average occupancy of each buffet 5. Calculate the probabilities of blockages and starvations of all machines 6 Assuming that the moulli buffer capacity is increased by a factor of 2. recalculate the production rate. Does it make practical sense to have all buffer capacities increased 7. Assume that efficiency of all Bemoulli machines is increased by 10% and again recalculate the production rate. Docsit make sense to have efficiencies increased 8. Determine if this system is WF-improvable. If so, calculate the imperable work allocation and the resulting productionale 9. Determine if this system is BC-improvable. If so, calculate the imposable buffor capacity allocation and the resulting production rate. 10. Calculate the simultaneously unimprovable WF and BC allocations and the resulting productie rate 11. Which, if any of the above improvement projects would you recommend for implementation 12. Identify its BN-m (or PBN-m) and BN and determine if the buffering is 13. Based on this information, design the best from your point of view, continuous improvement project that results in 10% increase of the productie rate of the system (as compared with the original one) 14. Using the B-exp transformation, return to the exponential description and formulate measures, which would have to be carried out in order to implement this continuous improvement project Problem 1. (45 Points). The layout of a production system for an automotive ignition device is shown in the following Figure It consists of four main operations: Housing Subassembly, Valve Body Ansembly. Injector Subassembly, and Injector Final Assembly. In addition, the system contains Shell Assembly, three Welding operations (L.HW. UW. and Weld two Overmold operations (O.M.I and O.M.2), two Set Stroke operations (Stroke land Stroke 2), one Leak Test operation (LT.) and one High Potential operation (IP) Finally, the system includes five buffers positioned as shown in the Figure and conveyor buffering among all other operations 2. Construct a structural model for this system and simplify it to a serial line. . Assume that the first five machines are of interest and their parameters are as follows: 2-10:0025;0.0011;0.0016 0.0031:0:0042] (in units of t/min -0.025 0.0333;0.025 0.0086, 0.05] (in units of limin 1:0714, 1:0714.06667; 0.9375; 1)(in units of parts in N-26 10:28:30) 1. Construct the Bemoulli model of this Five-machine exponential seriale 2. Using the Simulation function of the PSE Toolbes, investigate the accuracy of the Bemoulli model 3. Calculate the production rate of this system, 4. Calculate the average occupancy of each buffer 5. Calculate the probabilities of blockages and starvations of all machines 6. Assuming that the Bemoulli buffer capacity is increased by a factor of 2. recalculate the production rate. Does it make practical sense to have all buffer capacities increased 7. Assume that efficiency of all Bemoulli machines is increased by 10% again recalculate the production rate. Does it make sense to have all efficiencies increased & Determine if this system is WF-improvable. If so, calculate the unimpovable work allocation and the resulting production rate. 9. Determine if this system is BC-omprovable. If so, calculate the impoble buffer capacity allocation and the resulting production rate. 10. Calculate the simultaneously unimprovable WF and BC allocations and the resulting production rate 11. Which, if my of the above improvement projects would you recommend for implementation 12. Identify in BN--. (or PBN-m) and BN band determine if the buffering is potent 13. Based on this information, design the best from your point of view. continuous improvement project that results in 10% increase of the production rate of the system (as compared with the original one) Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock