Question: It is required to establish Upper and Lower Quality Control limits on the weight of a semolina product produced in a Flour Mills Factory. 1

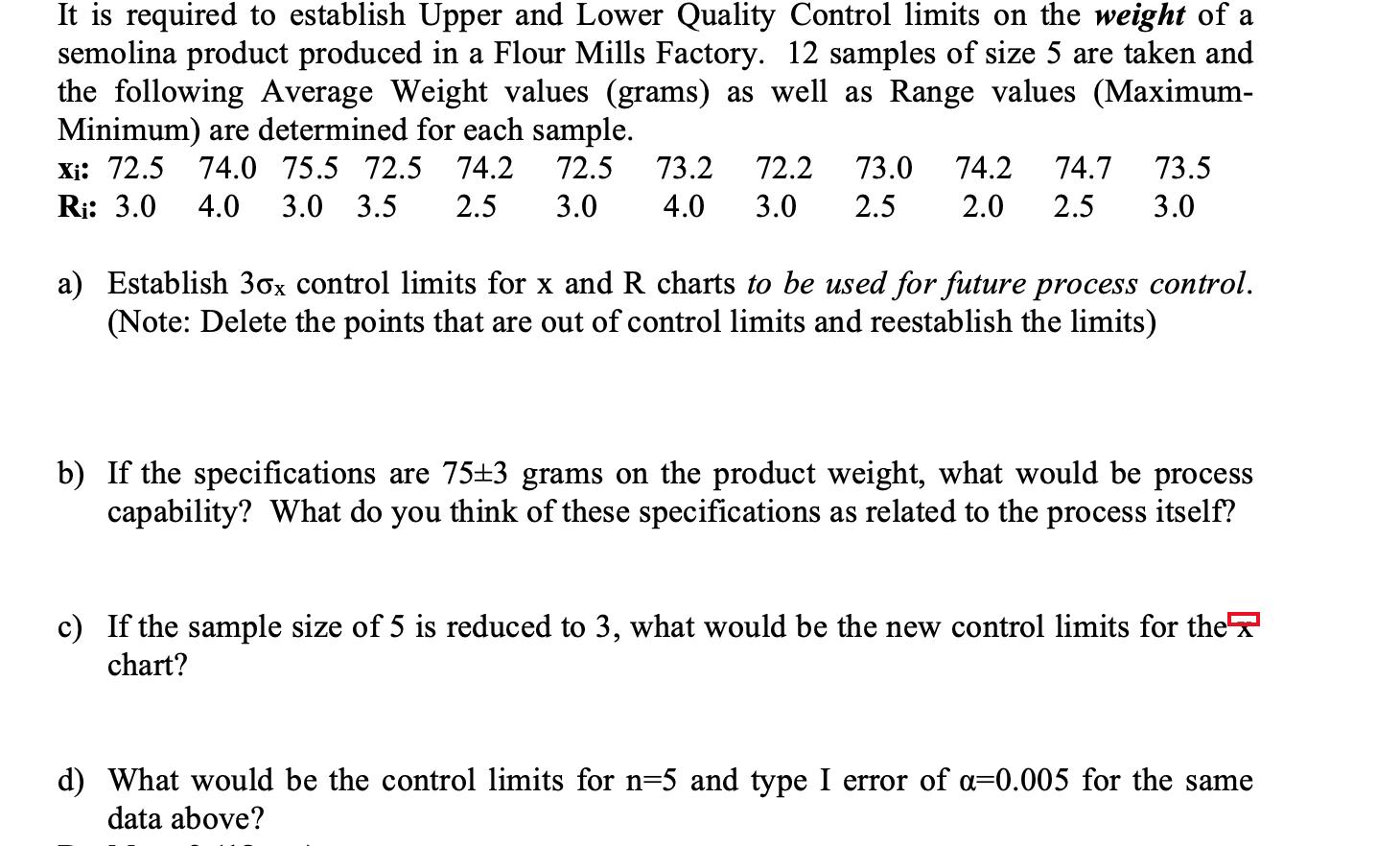

It is required to establish Upper and Lower Quality Control limits on the weight of a semolina product produced in a Flour Mills Factory. samples of size are taken and the following Average Weight values grams as well as Range values MaximumMinimum are determined for each sample.

tablei:

a Establish control limits for and charts to be used for future process control. Note: Delete the points that are out of control limits and reestablish the limits

b If the specifications are grams on the product weight, what would be process capability? What do you think of these specifications as related to the process itself?

c If the sample size of is reduced to what would be the new control limits for the chart?

d What would be the control limits for and type I error of for the same data above?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock