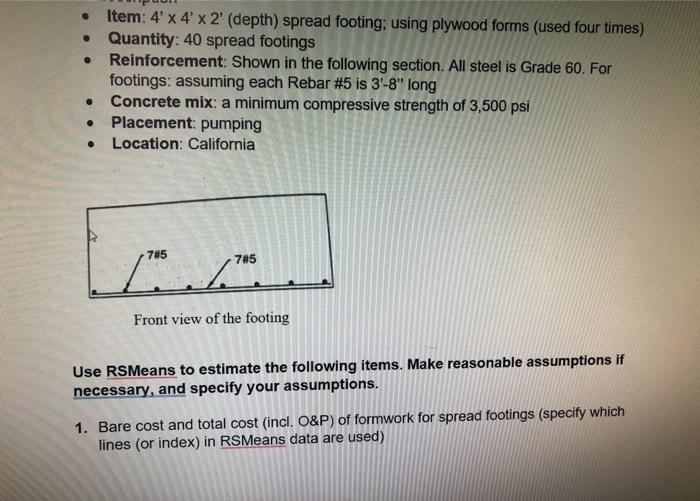

Question: Item: 4' x 4' x 2 (depth) spread footing; using plywood forms (used four times) Quantity: 40 spread footings Reinforcement: Shown in the following section.

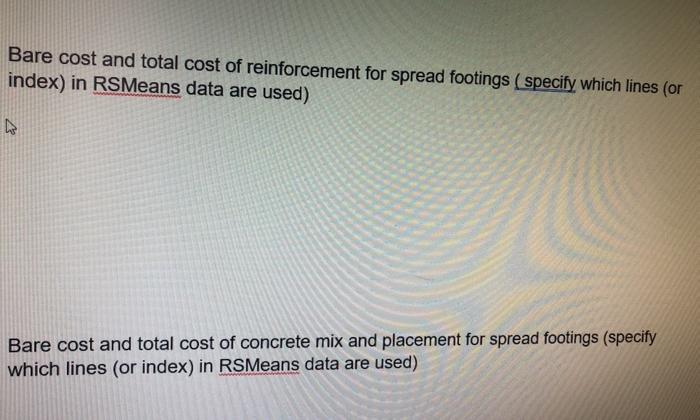

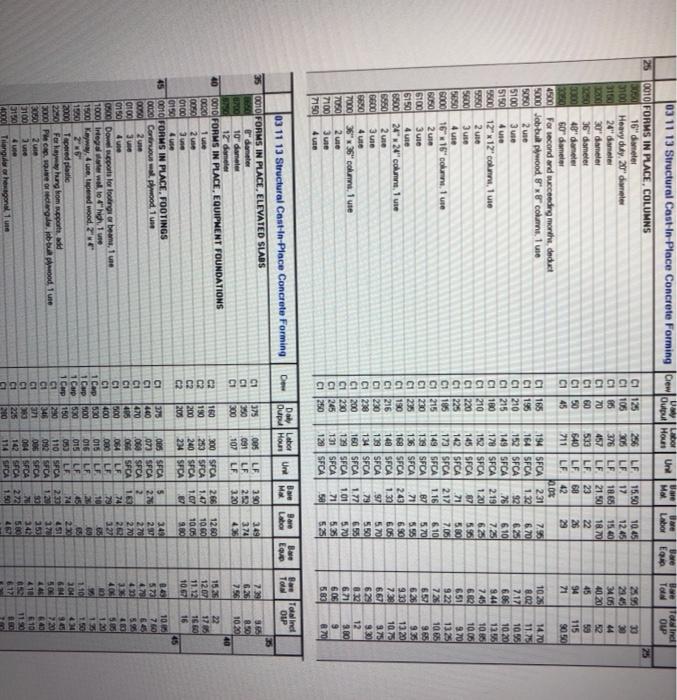

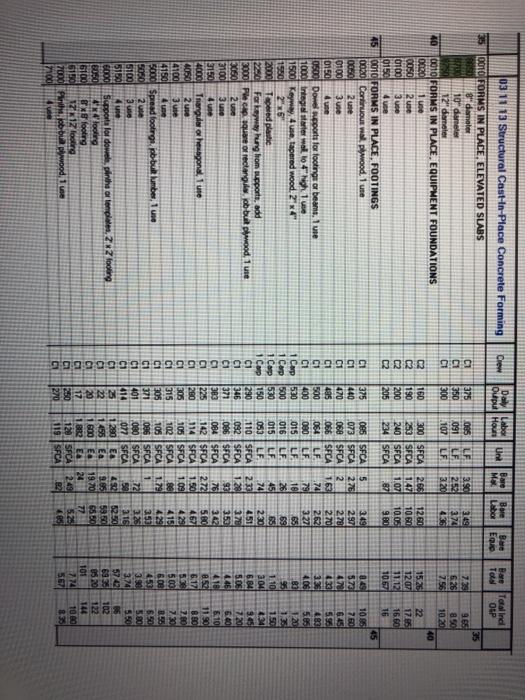

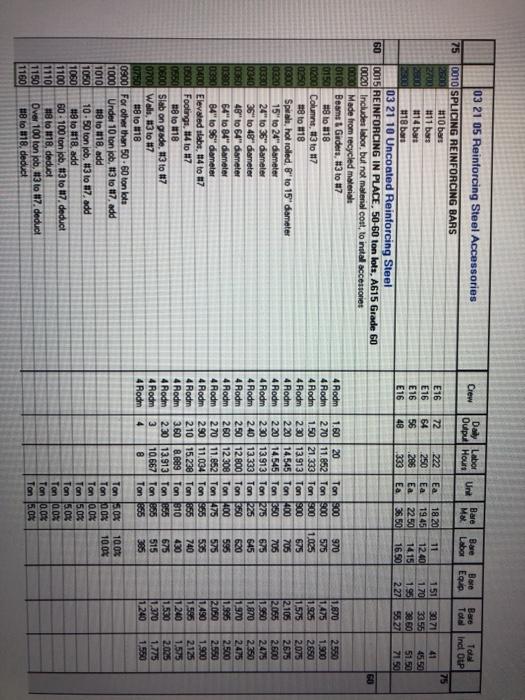

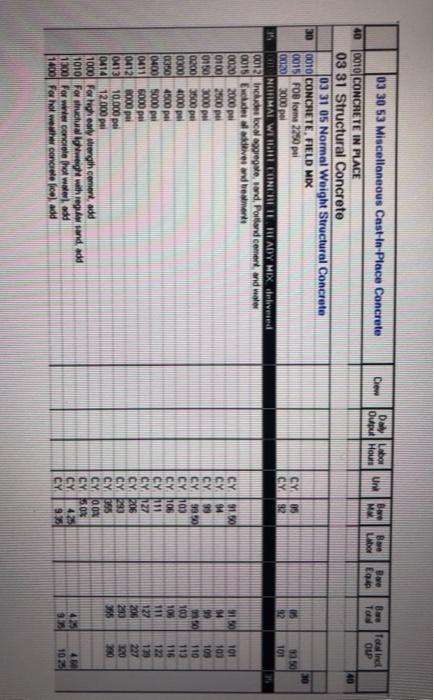

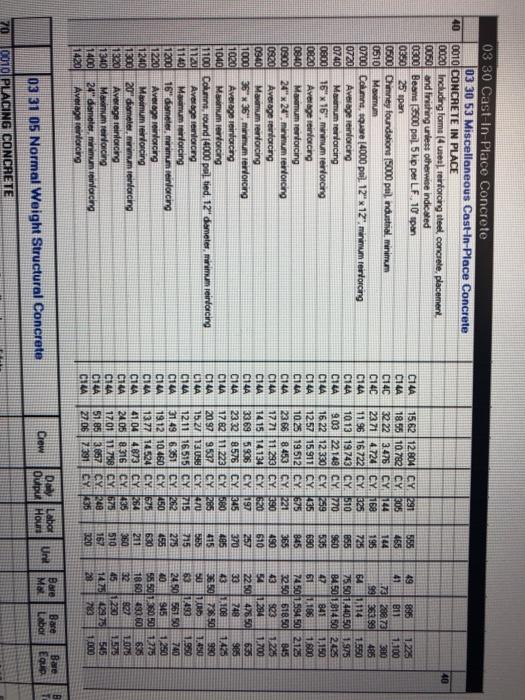

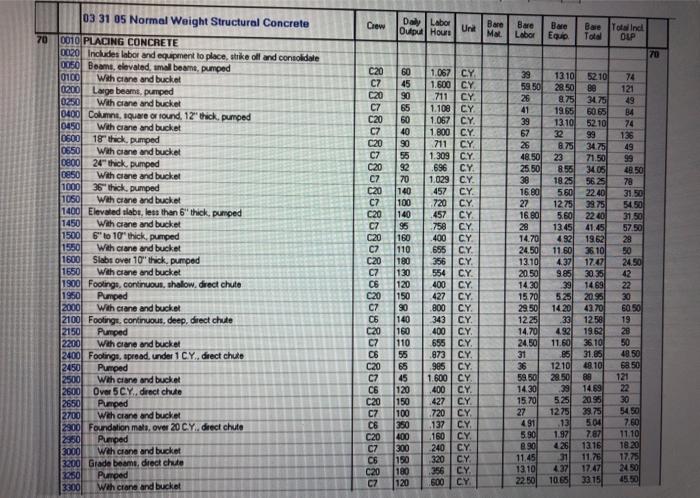

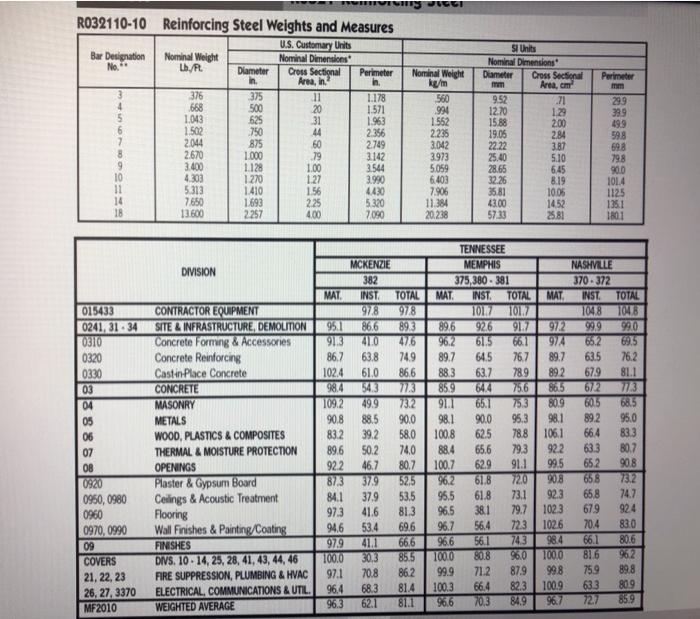

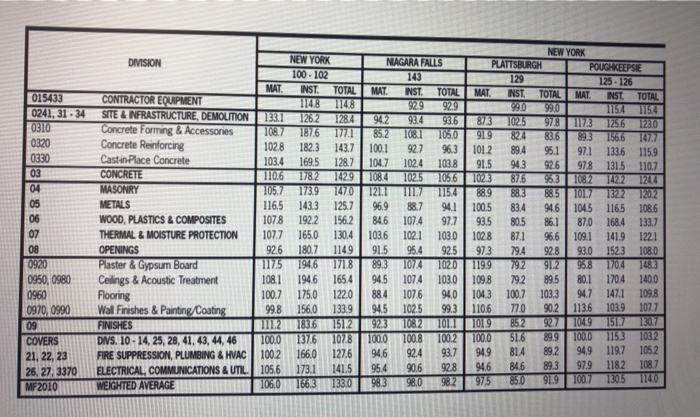

Item: 4' x 4' x 2 (depth) spread footing; using plywood forms (used four times) Quantity: 40 spread footings Reinforcement: Shown in the following section. All steel is Grade 60. For footings: assuming each Rebar #5 is 3-8" long Concrete mix: a minimum compressive strength of 3,500 psi Placement: pumping Location: California . . 7#5 785 Front view of the footing Use RSMeans to estimate the following items. Make reasonable assumptions if necessary, and specify your assumptions. 1. Bare cost and total cost (incl. O&P) of formwork for spread footings (specify which lines (or index) in RSMeans data are used) Bare cost and total cost of reinforcement for spread footings (specify which lines (or index) in RSMeans data are used) Bare cost and total cost of concrete mix and placement for spread footings (specify which lines (or index) in RSMeans data are used) Uwe Labor Bare Equip TON Tot ind OUP 25 25 1085 12.45 15.00 18701 22 26 29 29 44 2596 2185 3406 4020 45 94 71 115 9050 1470 103 11 13 Structural Cast In Place Concrete Forming Crew Labor re Un Output How Mal 0010 FORMS IN PLACE, COLUMNS 16" diameter Ci 125 256 LF 15.50 3100 Heavy duty, 20 dite CI 105 305 LE 17 3150 24" domate C1 85 376 LF 18.68 DO 30 diameter CI 70 457 LF 21.50 3250 36'dameter C1 60 533 LF23 48" diameter C150 640 LF 68 3000 60" diameter C1 45 711 LF 42 4500 For second and succeeding monte deduct 100 5000 Jobbul plywood 8x columns 1 uie Ci 1165 194 SFCA 231 5050 2 use C1 195 164 SFCA 134 5100 3 use CL 210 152 SFCA 92 5150 4 use CI 215 149 SFCA 26 9600 12" x 12 column, lule CI 180 178 SECA 219 5550 2 uie C1 210 152 SFCA 1.20 5600 3 CI 220 145 SFCA 87 5650 4 use C1 1225 142 SFCA 71 6000 16164 colum. 1 use CI 195 173 SFCA 217 6050 2uia CI 1215 149 SFCA 116 5100 3uie CI 1200 139 SFCA B7 6150 4 ure C1 235 126 SFCA 6500 2024 columns 1 ure C1 130 168 SFCA 243 2u CI 1216 140 SFCA 1.30 6600 June CI 230 139 SFCA 97 6830 4 u CI 120 1:34 SFCA 79 7000 36" 36"com, 1 ute C1 200 160 SFCA 1.77 C1 230 7050 179 SFCA 1.01 7100 3ute CI 245 131 SECA 71 7150 4 CI 250 129 SFCA 50 7.55 6.70 625 6.10 725 625 550 5.80 705 6.10 570 5.55 1025 8.02 717 686 944 7.45 6.82 6.51 922 726 652 6.26 933 739 6.67 625 822 11.7 1055 1020 1255 10.80 10.05 970 1325 1085 9.65 690 605 570 5.50 655 570 535 525 1320 1075 975 930 12 3.80 9 870 67 2 use 606 583 Dew Day Labor Dupl Hous Unit Bare Bare Mal Labor 03 11 13 Structural Cost-in-Place Concrete Forming Bu ED Be Tin TOWN OLP C1 CI 375 350 300 005 091 107 LF LF LF 390 2591 3200 149 374 40 7.39 6.26 7.56 850 1020 40 C2 02 C2 160 130 200 205 300 SFCA 253 SFCA 240 SFCA 204 SFCA 266 1.47 1.07 89 1280 1000 100 9.80 1535 12.07 11.12 1067 1786 1660 16 45 10 7.60 35 0010 FORMS IN PLACE, ELEVATED SLADS rdameter BO 10 meter ON 12 deler 40 0010 FORMS IN PLACE, EQUIPMENT FOUNDATIONS 0020 1 0050 2 use 0100 0150 4 450010 FORMS IN PLACE, FOOTINGS 0020 Corous wol plywood. 1 un 0000 2 0100 3 0150 4 000 Dow eports for longer bene, une 1000 trtegal wel to Chich we 1500 Kaway we tapered wood, NC 1900 ZN 2000 Tapered plac 2220 Forkay.whung kom support add 3000 Pep. Nenectarglwb bu plywood 1 ute 3030 2u 3100 3150 4000 Tilanguro hexagonal 1 SITR999999 DORS 909 349 230 270 270 573 470 3351 321 375 CI 1440 C! 470 CD C1 500 CI 400 1 Cap 530 1 Cap 500 1 Carp 530 1 Cup 150 CI 290 CI 346 CI 311 CI 380 ci 225 CH 210 40 005 SFCA 5 07 SFCA 270 069 SFCA 2 066 SFCA 10 064 LF 74 LF 29 016 LF 10 016 LF 015 LF LE 74 110 SFCA2.30 092 SFCA 005 SFCA 99 004 SFCA 142 SFCA 2731 114 SPCA 1.50 5% 489 SES 1 133 150 6.9 65 230 451 27 1.100 204 6. 50 446 410 720 640 341 50 110 617 03 11 13 Structural Cast-in-Place Concrete Forming Crew Daly Cabo Qupd How Bu Bale Und MI Bue EC Bare Totalind To OIP 350 300 085 091 LF LF LF 39 252 320 249 374 436 7.39 6.26 7.56 102 40 D2 C2 C2 C2 160 190 200 205 300 SFCA 266 250 SFCA 1.47 240 SFCA 1.07 234 SFCA 87 1280 10.60 10.05 980 15.25 1207 11.12 1062 35 9.65 8.50 10 20 40 22 17.95 16.60 16 45 1085 760 645 45 506 0000 555558888 249 573 478 130 SS 015 0010 FORMS IN PLACE, ELEVATED SLABS g dameler 10" diameter 12" diameter 0010 FORMS IN PLACE, EQUIPMENT FOUNDATIONS DORO 1 0050 2 use 0100 3 0150 Ace 0010 FORMS IN PLACE, FOOTINGS 0020 Continuous walkwood. 1 use 0350 2 use 10100 3 use 0150 4 use 0500 Done support for footings or beamo. Tule 1000 Integral starter wel to high 1500 Keyway, 4 use, tapered wood. 2x 1980 26 2100 Tapered plastic 2280 Forkeay hung hom supports, add 3000 Plec square of rectangul ob but wood. 1 uit 2050 2 3100 3 un 3150 4 we 4000 Triangular hesagonal. Tule 4050 2 u 4100 3 ure 4150 5000 Spread forge.pb-buk lumber, 1ure 5050 2 use 5100 a une 5150 4u 000 Support for dowels, the area. ZNZ forg EURO looking 6100 & fooling 6180 17x1Z long 7000fthebb pood 1 7100 338 4.08 B3 5 1.10 304 684 5.06 4.89 5.85 1:20 1.38 1.50 451 27 46 375 CI 440 C1 1470 C1 495 500 400 1 Cap 530 1 Cap 500 1 Cup 530 1 150 C1 230 346 371 383 225 280 30 315 305 371 401 410 23 22 20 17 250 270 085 SFCA 5 3.49 073 SFCA 276 297 060 SFCA 2 278 066 SFCA 1.63 270 064 LF 74 262 080 LF 79 327 LF 65 016 LF 26 69 015 LF 45 65 053 LF 74 230 110 SFCA 233 092 SFCA 1.28 086 SFCA 93 350 084 SFCA 76 342 142 SFCA 272 SBC 114 SECA 1.50 467 105 SFCA 1.09 429 102 SFCA 80 415 105 SFCA 179 429 096 SFCA 1 080 SFCA 72 2.26 on SFCA 59 216 1 290E 492 52.50 1455E 9.85 59.50 1600 ES 19.70 650 100 24 77 120 SFCA 249 5.25 119 SFCA B2 85 418 852 6.17 338 05565656666scississ 500 8.08 453 3.98 9.45 7.20 640 6.10 1190 8.80 7.80 7.30 3.55 650 5.00 5.50 85 102 122 144 100 83 250 2.74 574 6936 8529 101 567 03 21 05 Reinforcing Steel Accessories Ciew Daily Labor Outpu Hours Un Bare Mar Base Bare Labor Equo 75 E16 E16 E16 E16 72 64 56 48 222 250 286 333 18.20 1945 22 50 36,50 Ea Ea Ea 11 12.40 14.15 16.50 Base Total Total Incl OTP 75 30 71 41 33.55 45.50 38.50 51.50 55 27 71.50 151 1.70 1.95 227 60 60 970 575 0010 SPLICING REINFORCING BARS #10 bars 2700 #11 bars 2.00 14 bars 18 bars 03 21 10 Uncoated Reinforcing Steel 0015 REINFORCING IN PLACE, 50-60 ton lots, A615 Grade 60 0020 Includes labor, but not material cost, to install accessories 0030 Made from recycled material 0100 Beans Giders, #3 to 17 0150 H8 to 818 0200 Columns, #3 to 817 0250 8 to 18 0300 Speal, hot rolled, 8 to 15 diameter 0620 15 to 24" diameter 0330 24 to 36" diameter 0340 36" to 48 diameter 0360 48" to 64" diameter 0390 64 to 84" diameter 0390 84" to 96 diameter 0400 Elevated labs, 4 to 7 3500 Footings, #14 to #17 0550 8 to 2018 0600 Slab on grade 113 to #7 0700 Walls, 3 to #7 0750 #8 to 18 0900 For other than 50 - 60 ton lots 1000 Under 10 ton job, 13 to 17. add 1010 8 to 18, add 1050 10.50 ton job, #3 to 87. add 1060 #8 to #18, add 1100 50 - 100 ton job, 83 to 17. deduct 11100 H8 to 2018, deduct 1150 Over 100 ton job. 83 to 17. deduct 1160 #8 to 318, deduct 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 1.60 20 Ton 300 270 11.852 Ton 300 1.50 21.333 Ton 300 230 13.913 Ton 300 220 14.545 Ton 400 220 14.545 Ton 350 230 13.913 Ton 75 240 13.333 Ton 1225 250 128001 Ton 350 2.60 12308 Ton 400 270 11.852 Ton 475 2.90 11.034 Ton 355 210 15 238 Ton 855 3.60 8.689 Ton 910 2.30 13.913 Ton 355 3 10.667 Ton 985 4 8 Ton 855 675 705 705 675 645 620 535 575 535 740 430 675 515 385 1.870 1.475 1.925 1.575 12.105 2055 1.950 1,870 1.970 1.995 2050 1.490 1.595 1.240 1.530 1.370 1.240 2.550 1,900 2650 2,075 2675 2.600 2475 2350 2.475 2500 2.550 1.900 2125 1,575 2.025 1.775 1.550 10.0% 10.0% Ton 50% Ton 100% Ton 100% Ton 5.0% Ton 50% Ton 100% Ton 0.0% Tan 5.0% Cew Day Labor Op Hour Une BN M Be Eg B Tail To OUP 40 CY05 CYA 2 22 12.50 101 03 30 53 Miscellaneous Cast-in-Place Concrete 40 0010 CONCRETE IN PLACE 03 31 Structural Concrete 03 31 05 Normal Weight Structural Concrete 30 0010 CONCRETE, FIELD MIX 0015 FOB forma 2250 p 0020 3000 pl I NORMAL WEIGHT CONCHI ILHADY MIX delivered 0012 Inch local aggregowand Portland come and water 0015 Exclude lives demande 0020 2000 pa 0100 2500 pa 0150 3000 pl 0200 3500 pel 0300 4000 pl 0.350 4500 pl 0400 5000 pe 0411 6000 pl 0412 8000 poi 0413 10.000 pel 0414 12.000 pl 1000 Fortugheally wength cemer, add 1010 Forucu gweight with regum id add 13.00 For we concrete het wel 1400 Forhol concrete cel add CY9150 CYM CY CY 9830 CY ho CY106 CY 11 CY27 CY 06 CY293 CY. 355 CY ON CYSOX CY 425 CY 98 Sol M 99 mo 100 100 111 122 206 233 055 101 103 103 110 113 116 122 129 227 220 425 105 480 1025 40 40 25 upan 465 03 30 Cast-In-Place Concrete 03 30 53 Miscellaneous Cast-In-Place Concrete 0010 CONCRETE IN PLACE 0020 Including forms (4 uses, tentoring the concrete, placement 0050 and finishing unless otherwise indicated 10300 Beams (3500 psl. 5 kip per LF. 10 span 0350 0500 Chimney foundation (5000 pindustrial, minimum 0510 Maximum 0700 Columns, que [4000 pu]. 12" x 17", minimum restoring 0720 Average reinforcing 0740 Msimum tortorcing 0900 16" 16.mum renforcing 0820 Average reinforcing 0840 Msimum Tortorcing 0900 24x24. minimum renorcing 0820 Average reinforcing 0940 Maximum renforcing 1000 36" 36" minimum reinforcing 1020 Average reinforcing Maximum erforcing 1100 Columns, round (4000 pul tied, 12" diameter, minimum reinforcing 1120 Average remorcing 1140 Maramum norcing 1200 16" diameter, minimum reinforcing 1220 Average reinforcing 1240 Maimum enorcing 1300 20 diameter, mentoring 1320 Average reinforcing 1340 Maximum tenforcing 1400 24" diameter,minum reinforcing Average reinforcing C14A CILA C14C C14C C1AA C14A CIU C14A CIUA CILA C144 CHLA C14A C14 CILA CHA CILA CILA CIA CILA CILA CILA CILA C14 CILA 15 62 12.804 CY 1291 18.55 10.782 CY 305 32.22 3.476 CY144 23.71 4.724CY. 168 11.96 167221 CY 325 10.13 19.743 CY510 903 22148 CY 770 16 22 12 330) CY 259 1257 15.911 CY. 435 10.25 19.512) CY. 675 23 66 8453 CY1221 1771 11.293 CY 390 14.15 14.134 CY 520 33695936 CY1197 23.328576CY. 345 17.82 11.223CY. 580 20 9795371 CY 285 15.27 13.088CY 470 12.11 16.515 CY 715 31.496351 CY262 19.12 10.460 CY 150 1377 14524 CY 675 41044.873 CY 254 24.058.316 CY 435 17.01 11.758 CY 675 51,853 857 CY: 248 27.06 7391 CY435 144 195 725 855 960 535 690 845 365 490 610 257 370 485 415 49 896 1 225 41 BI 1.100 73 288.73 380 99 363.99 485 64 1.114 1.550 75.50 1.440.50 1.975 B4.50 1 814 50 2.125 47 841 1,150 61 1.186 1600 7450159450 2.125 3250618 50 845 13 $23 1225 541.284 1.700 2250 47650 636 33 748 ses 43 1.108 1.425 36.50 73850990 SU 63 1.493 24.50 561 50 740 40 $45 1.250 58 50 1.380 90 12775 18 60 493 60 635 32 822 1.075 45 11 230 1.575 1475 12975 545 23 783 1.000 1040 1.00 715 455 630 211 360 510 167 320 1420 Daly Labor Outpur Hours Unit Bare Mal Bare Labor Bare Eque B T Crew 03 31 05 Normal Weight Structural Concrete 700010 PLACING CONCRETE 03 31 05 Normal Weight Structural Concrete Crew Daly Labor Dupu Hours Unit Bar Mak Bare Labor Bare 70 Bare Total Inch Total 70 OUP C20 C7 C20 C7 C20 C7 3475 CY C7 C20 C20 C7 C20 0010 PLACING CONCRETE 0020 Includes labor and equipment to place, strike off and consolidate 0050 Beams, elevated, smal beame, pumped 0100 Wshcrane and bucket 0200 Large beams, pumped 0250 With crane and bucket 0400 Columns, que or found 12" thick, pumped 0450 With cine and bucket 0600 18 thick, pumped 0650 Wihciane and bucket 0800 24" thick, pumped 0850 With crane and bucket 1000 36 thick, pumped 1050 With crane and bucket 1400 Elevated slabi, less than 5 thick, pumped 1450 With crane and bucket 15006" to 10 thick, pumped 1550 With crane and bucket 1600 Slabs over 10" thick, pumped 1650 With crane and bucket 1300 Footings, continuous shalow, direct chute 1950 Pumped 2000 Wih crane and bucket 2100 Footing, continuous, deep, direct chute 2150 Pumped 2200 With care and bucket 2400 Fookings, spread, under 1 CY, direct chute 2450 Pumped 2500 Wihcian and bucket 2600 Over 5 CY, direct chute 2650 Pumped 2700 Wah crane and bucket 2800 Foundation mat, over 20 CY. direct chute 2850 Pumped 3000 We crane and bucket 3200 Grade beams, direct chute 32.50 Pumped 3300 We crane and bucket 089988988098928988989898989898989898 C20 C7 45 90 65 50 40 90 55 92 70 140 100 140 95 160 110 180 130 120 150 90 140 160 110 55 65 45 120 150 100 350 400 300 150 180 120 1.067 CY 1.600 CY 711 CY 1.109 CY 1.067 CY 1.800 CY 711 1.309 CY 696 CY 1,029 CY 457 CY 720 CY 457 CY . 758 CY 400 CY 655 CY 356 CY 554 CY 400 CY 427 CY CY CY CY CY CY CY 1.600 CY CY . 720 CY CY 160 CY 240 CY CY 356 CY 600 CY 1310 52.10 5950 28.50 BE 26 8.75 41 19.65 60 65 39 13.10 52.10 67 32 99 25 8.75 34.75 48.50 23 71.50 25.50 8.55 3405 38 18 25 5625 16.80 560 22.40 27 1275 29.75 16.80 5.60 2240 28 13.45 41.45 14.70 499 1962 24.50 11.60 3610 13.10 437 170 20.50 9.85 30 35 14.30 39 1469 1570 525 20.96 29.50 1420 42.70 12.25 33 1258 14.70 4.92 1962 24.50 36.10 31 85 31.85 36 1210 48.10 59.50 28.50 88 14.30 39 14.89 15.70 525 2095 27 1275 28.75 491 13 504 5.90 197 8.90 426 13.16 11.45 31 11.76 1310 4.37 17.47 22 50 10.65 33.15 C20 74 135 49 99 48.50 78 31.50 54.50 31,50 57.50 28 30 24.50 42 22 30 50 50 19 ZB 50 48.50 68.50 121 22 30 5450 7.60 11.10 18 20 17.75 24 50 45.50 C6 C20 C C6 11.60 C20 C7 C20 C20 C7 C6 C20 C7 HVIS JEG R032110-10 Reinforcing Steel Weights and Measures Bar Designation No. Nominal Weight Lb/. Diameter Nominal Weight Perimeter 4 129 U.S. Customary Units Nominal Dimensions Cross Sectional Area, in 11 20 31 44 60 79 376 668 1,043 1.502 2044 2.670 3.000 4303 5313 7650 13.600 299 389 375 500 625 750 875 1.000 1128 1270 1.410 1693 2.257 Perimeter in. 1.178 1.571 1.963 2 356 2749 2.142 3544 3.990 4430 5320 7090 560 994 1.552 2.235 3,042 3973 5.059 Si Units Nominal Dimensions Diameter Cross Sectional Area, cm 9.52 .71 12.70 15.88 200 19.05 284 22.22 3.87 25.40 5.10 28.65 645 32.26 8.19 35.81 10:06 13.00 1452 5733 2581 100 9 10 11 127 1.56 225 4.00 598 698 798 900 1014 1125 1351 1801 7.906 11,384 20.238 18 DIVISION 015433 0241.31 - 34 0310 0320 0330 03 04 05 06 07 08 0920 0950, 0980 0960 0970, 0990 09 COVERS 21, 22, 23 26, 27, 3370 MF2010 MCKENZIE 382 MAT INST TOTAL 978 978 951 86,6 893 91.3 410 47.6 86.7 63.8 749 1024 61,0 86.6 98.4 543 109.2 49.9 73.2 90.8 88.5 90.0 83.2 58.0 89.6 50.2 74,0 922 46.7 80.7 873 379 52.5 84.1 37.9 53.5 97.3 41.6 81.3 94,6 53.4 69.6 979 41.1 66.6 100.0 30.3 855 97.1 70.8 862 96.4 68.3 81.4 96.3 62.1 81.1 CONTRACTOR EQUIPMENT SITE & INFRASTRUCTURE, DEMOLITION Concrete Forming & Accessones Concrete Reinforcing Castin Place Concrete CONCRETE MASONRY METALS WOOD, PLASTICS & COMPOSITES THERMAL & MOISTURE PROTECTION OPENINGS Plaster & Gypsum Board Celings & Acoustic Treatment Flooring Wall Finishes & Painting/Coating FINISHES DIVS. 10. 14, 25, 28, 41, 43, 44, 46 FIRE SUPPRESSION, PLUMBING & HVAC ELECTRICAL, COMMUNICATIONS & UTIL. WEIGHTED AVERAGE 39.2 TENNESSEE MEMPHIS NASHVILLE 375,380 - 391 370-372 MAT INST TOTAL MAT INST. TOTAL 1017 101.7 1048 1048 89.6 926 917 972 999 99.0 96.2 61.5 661 974 652 69.5 89.7 64.5 767 89.7 63.5 76.2 883 63.7 789 892 679 811 859 644 756 86.5 672 773 911 65.1 753 809 60.5 685 98.1 90.0 95.3 98.1 892 95.0 100.8 62,5 78.8 1061 66.4 833 88.4 65.6 79.3 922 63.3 B07 100,7 62.9 995 652 90.8 96.2 61.8 720 908 658 73.2 95.5 61.8 73.1 92.3 658 74.7 96.5 38.1 79.7 1023 679 96.7 56.4 723 1026 70.4 83.0 96.6 561 743 98.4 661 80.6 10010 80.8 $6.0 100.0 8! 6 962 99.9 71.2 87.9 998 759 89.8 100.3 66.4 82.3 100.9 63.3 809 966 70,3 84.9 96.7 727 859 91.1 INST 936 927 91.5 1086 NEW YORK DIVISION NEW YORK NIAGARA FALLS PLATTSBURGH POUGHKEEPSE 100.102 143 129 125 126 MAT INST TOTAL MAT CONTRACTOR EQUIPMENT INST TOTAL MAT TOTAL MAT 1148 1148 INST TOTAL 929 929 990 SITE & NFRASTRUCTURE, DEMOLITION 99.0 1154 1154 1331 1262 1284 942 93.4 87.3 102.5 Concrete Forming & Accessories 97.81173 108.7 1256 1876 1771 120 852 108.1 1050 919 824 8316 Concrete Reinforcing 1566 1028 182.3 143.7 100.1 96.3 1012 894 95.1 97.1 1336 Castin Place Concrete 1159 103.4 169,5 128.7 104.7 1024 103.8 94.3 926 978 1315 CONCRETE 110.7 1106 17821429 1084 102.5 1056 1023 87.6 963 1082 142.2 1244 MASONRY 1057 1739 1470 121.1 1154 889 883 8851017 1522 120.2 METALS 116.5 143.3 125.7 96.9 88.7 941 100.5 83.4 94.6 1045 1165 WOOD, PLASTICS & COMPOSITES 1078 192.2 156.2 846 97.7 93.5 80.5 86.1 87.0 1684 132.7 THERMAL & MOISTURE PROTECTION 107.7 165.0 130.4 103.6 102.1 103.0 1028 87.1 9661091 1419 1221 OPENINGS 92.6 180.7 1149 91.5 95.4 92.5 79.4 92.8 93.0 1523 108.0 Plaster & Gypsum Board 1175 194.6 1718 89.3 1074 1020 1199 192 912 958 1704 103 Ceilings & Acoustic Treatment 1081 1946 165.4 94.5 107.4 103.0 109.8 792 895 80:1 170.4 1400 Flooring 100.7 175.0 1220 88.4 107.6 94.0 1043 100.7 103.3 94.7 147.1 109.8 Wall Finishes & Painting/Coating 99.8 156,0 1339 945 102.5 99.3 110.6 77.0 902 113.6 1039 107.7 FINISHES 1112 1836 1512 923 108.2 1011 1019 852 1049 1517 13027 DIVS. 10-14, 25, 28, 41, 43, 44, 46 100.0 137.6 1078 100.0 100.8 1002 1000 51.6 899 100.0 1153 1032 FIRE SUPPRESSION, PLUMBING & HVAC 1002 166,0 127.6 946 92.4 93.7 949 814 892 94.9 1197 1052 ELECTRICAL, COMMUNICATIONS & UTIL 105.6 173.1 141.5 95.4 90,6 928 89.3 97.91182 1087 106.0 WEIGHTED AVERAGE 1663 133.0 98.3 98.0 932 975 85.0 91.9 100.713013 1140 015433 0241, 31-34 0310 0320 0330 03 04 05 06 07 08 0920 0950, 0980 0960 0970, 0990 09 COVERS 21, 22, 23 26, 27, 3370 MF2010 107.4 973 946 846 Item: 4' x 4' x 2 (depth) spread footing; using plywood forms (used four times) Quantity: 40 spread footings Reinforcement: Shown in the following section. All steel is Grade 60. For footings: assuming each Rebar #5 is 3-8" long Concrete mix: a minimum compressive strength of 3,500 psi Placement: pumping Location: California . . 7#5 785 Front view of the footing Use RSMeans to estimate the following items. Make reasonable assumptions if necessary, and specify your assumptions. 1. Bare cost and total cost (incl. O&P) of formwork for spread footings (specify which lines (or index) in RSMeans data are used) Bare cost and total cost of reinforcement for spread footings (specify which lines (or index) in RSMeans data are used) Bare cost and total cost of concrete mix and placement for spread footings (specify which lines (or index) in RSMeans data are used) Uwe Labor Bare Equip TON Tot ind OUP 25 25 1085 12.45 15.00 18701 22 26 29 29 44 2596 2185 3406 4020 45 94 71 115 9050 1470 103 11 13 Structural Cast In Place Concrete Forming Crew Labor re Un Output How Mal 0010 FORMS IN PLACE, COLUMNS 16" diameter Ci 125 256 LF 15.50 3100 Heavy duty, 20 dite CI 105 305 LE 17 3150 24" domate C1 85 376 LF 18.68 DO 30 diameter CI 70 457 LF 21.50 3250 36'dameter C1 60 533 LF23 48" diameter C150 640 LF 68 3000 60" diameter C1 45 711 LF 42 4500 For second and succeeding monte deduct 100 5000 Jobbul plywood 8x columns 1 uie Ci 1165 194 SFCA 231 5050 2 use C1 195 164 SFCA 134 5100 3 use CL 210 152 SFCA 92 5150 4 use CI 215 149 SFCA 26 9600 12" x 12 column, lule CI 180 178 SECA 219 5550 2 uie C1 210 152 SFCA 1.20 5600 3 CI 220 145 SFCA 87 5650 4 use C1 1225 142 SFCA 71 6000 16164 colum. 1 use CI 195 173 SFCA 217 6050 2uia CI 1215 149 SFCA 116 5100 3uie CI 1200 139 SFCA B7 6150 4 ure C1 235 126 SFCA 6500 2024 columns 1 ure C1 130 168 SFCA 243 2u CI 1216 140 SFCA 1.30 6600 June CI 230 139 SFCA 97 6830 4 u CI 120 1:34 SFCA 79 7000 36" 36"com, 1 ute C1 200 160 SFCA 1.77 C1 230 7050 179 SFCA 1.01 7100 3ute CI 245 131 SECA 71 7150 4 CI 250 129 SFCA 50 7.55 6.70 625 6.10 725 625 550 5.80 705 6.10 570 5.55 1025 8.02 717 686 944 7.45 6.82 6.51 922 726 652 6.26 933 739 6.67 625 822 11.7 1055 1020 1255 10.80 10.05 970 1325 1085 9.65 690 605 570 5.50 655 570 535 525 1320 1075 975 930 12 3.80 9 870 67 2 use 606 583 Dew Day Labor Dupl Hous Unit Bare Bare Mal Labor 03 11 13 Structural Cost-in-Place Concrete Forming Bu ED Be Tin TOWN OLP C1 CI 375 350 300 005 091 107 LF LF LF 390 2591 3200 149 374 40 7.39 6.26 7.56 850 1020 40 C2 02 C2 160 130 200 205 300 SFCA 253 SFCA 240 SFCA 204 SFCA 266 1.47 1.07 89 1280 1000 100 9.80 1535 12.07 11.12 1067 1786 1660 16 45 10 7.60 35 0010 FORMS IN PLACE, ELEVATED SLADS rdameter BO 10 meter ON 12 deler 40 0010 FORMS IN PLACE, EQUIPMENT FOUNDATIONS 0020 1 0050 2 use 0100 0150 4 450010 FORMS IN PLACE, FOOTINGS 0020 Corous wol plywood. 1 un 0000 2 0100 3 0150 4 000 Dow eports for longer bene, une 1000 trtegal wel to Chich we 1500 Kaway we tapered wood, NC 1900 ZN 2000 Tapered plac 2220 Forkay.whung kom support add 3000 Pep. Nenectarglwb bu plywood 1 ute 3030 2u 3100 3150 4000 Tilanguro hexagonal 1 SITR999999 DORS 909 349 230 270 270 573 470 3351 321 375 CI 1440 C! 470 CD C1 500 CI 400 1 Cap 530 1 Cap 500 1 Carp 530 1 Cup 150 CI 290 CI 346 CI 311 CI 380 ci 225 CH 210 40 005 SFCA 5 07 SFCA 270 069 SFCA 2 066 SFCA 10 064 LF 74 LF 29 016 LF 10 016 LF 015 LF LE 74 110 SFCA2.30 092 SFCA 005 SFCA 99 004 SFCA 142 SFCA 2731 114 SPCA 1.50 5% 489 SES 1 133 150 6.9 65 230 451 27 1.100 204 6. 50 446 410 720 640 341 50 110 617 03 11 13 Structural Cast-in-Place Concrete Forming Crew Daly Cabo Qupd How Bu Bale Und MI Bue EC Bare Totalind To OIP 350 300 085 091 LF LF LF 39 252 320 249 374 436 7.39 6.26 7.56 102 40 D2 C2 C2 C2 160 190 200 205 300 SFCA 266 250 SFCA 1.47 240 SFCA 1.07 234 SFCA 87 1280 10.60 10.05 980 15.25 1207 11.12 1062 35 9.65 8.50 10 20 40 22 17.95 16.60 16 45 1085 760 645 45 506 0000 555558888 249 573 478 130 SS 015 0010 FORMS IN PLACE, ELEVATED SLABS g dameler 10" diameter 12" diameter 0010 FORMS IN PLACE, EQUIPMENT FOUNDATIONS DORO 1 0050 2 use 0100 3 0150 Ace 0010 FORMS IN PLACE, FOOTINGS 0020 Continuous walkwood. 1 use 0350 2 use 10100 3 use 0150 4 use 0500 Done support for footings or beamo. Tule 1000 Integral starter wel to high 1500 Keyway, 4 use, tapered wood. 2x 1980 26 2100 Tapered plastic 2280 Forkeay hung hom supports, add 3000 Plec square of rectangul ob but wood. 1 uit 2050 2 3100 3 un 3150 4 we 4000 Triangular hesagonal. Tule 4050 2 u 4100 3 ure 4150 5000 Spread forge.pb-buk lumber, 1ure 5050 2 use 5100 a une 5150 4u 000 Support for dowels, the area. ZNZ forg EURO looking 6100 & fooling 6180 17x1Z long 7000fthebb pood 1 7100 338 4.08 B3 5 1.10 304 684 5.06 4.89 5.85 1:20 1.38 1.50 451 27 46 375 CI 440 C1 1470 C1 495 500 400 1 Cap 530 1 Cap 500 1 Cup 530 1 150 C1 230 346 371 383 225 280 30 315 305 371 401 410 23 22 20 17 250 270 085 SFCA 5 3.49 073 SFCA 276 297 060 SFCA 2 278 066 SFCA 1.63 270 064 LF 74 262 080 LF 79 327 LF 65 016 LF 26 69 015 LF 45 65 053 LF 74 230 110 SFCA 233 092 SFCA 1.28 086 SFCA 93 350 084 SFCA 76 342 142 SFCA 272 SBC 114 SECA 1.50 467 105 SFCA 1.09 429 102 SFCA 80 415 105 SFCA 179 429 096 SFCA 1 080 SFCA 72 2.26 on SFCA 59 216 1 290E 492 52.50 1455E 9.85 59.50 1600 ES 19.70 650 100 24 77 120 SFCA 249 5.25 119 SFCA B2 85 418 852 6.17 338 05565656666scississ 500 8.08 453 3.98 9.45 7.20 640 6.10 1190 8.80 7.80 7.30 3.55 650 5.00 5.50 85 102 122 144 100 83 250 2.74 574 6936 8529 101 567 03 21 05 Reinforcing Steel Accessories Ciew Daily Labor Outpu Hours Un Bare Mar Base Bare Labor Equo 75 E16 E16 E16 E16 72 64 56 48 222 250 286 333 18.20 1945 22 50 36,50 Ea Ea Ea 11 12.40 14.15 16.50 Base Total Total Incl OTP 75 30 71 41 33.55 45.50 38.50 51.50 55 27 71.50 151 1.70 1.95 227 60 60 970 575 0010 SPLICING REINFORCING BARS #10 bars 2700 #11 bars 2.00 14 bars 18 bars 03 21 10 Uncoated Reinforcing Steel 0015 REINFORCING IN PLACE, 50-60 ton lots, A615 Grade 60 0020 Includes labor, but not material cost, to install accessories 0030 Made from recycled material 0100 Beans Giders, #3 to 17 0150 H8 to 818 0200 Columns, #3 to 817 0250 8 to 18 0300 Speal, hot rolled, 8 to 15 diameter 0620 15 to 24" diameter 0330 24 to 36" diameter 0340 36" to 48 diameter 0360 48" to 64" diameter 0390 64 to 84" diameter 0390 84" to 96 diameter 0400 Elevated labs, 4 to 7 3500 Footings, #14 to #17 0550 8 to 2018 0600 Slab on grade 113 to #7 0700 Walls, 3 to #7 0750 #8 to 18 0900 For other than 50 - 60 ton lots 1000 Under 10 ton job, 13 to 17. add 1010 8 to 18, add 1050 10.50 ton job, #3 to 87. add 1060 #8 to #18, add 1100 50 - 100 ton job, 83 to 17. deduct 11100 H8 to 2018, deduct 1150 Over 100 ton job. 83 to 17. deduct 1160 #8 to 318, deduct 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 4 Rodm 1.60 20 Ton 300 270 11.852 Ton 300 1.50 21.333 Ton 300 230 13.913 Ton 300 220 14.545 Ton 400 220 14.545 Ton 350 230 13.913 Ton 75 240 13.333 Ton 1225 250 128001 Ton 350 2.60 12308 Ton 400 270 11.852 Ton 475 2.90 11.034 Ton 355 210 15 238 Ton 855 3.60 8.689 Ton 910 2.30 13.913 Ton 355 3 10.667 Ton 985 4 8 Ton 855 675 705 705 675 645 620 535 575 535 740 430 675 515 385 1.870 1.475 1.925 1.575 12.105 2055 1.950 1,870 1.970 1.995 2050 1.490 1.595 1.240 1.530 1.370 1.240 2.550 1,900 2650 2,075 2675 2.600 2475 2350 2.475 2500 2.550 1.900 2125 1,575 2.025 1.775 1.550 10.0% 10.0% Ton 50% Ton 100% Ton 100% Ton 5.0% Ton 50% Ton 100% Ton 0.0% Tan 5.0% Cew Day Labor Op Hour Une BN M Be Eg B Tail To OUP 40 CY05 CYA 2 22 12.50 101 03 30 53 Miscellaneous Cast-in-Place Concrete 40 0010 CONCRETE IN PLACE 03 31 Structural Concrete 03 31 05 Normal Weight Structural Concrete 30 0010 CONCRETE, FIELD MIX 0015 FOB forma 2250 p 0020 3000 pl I NORMAL WEIGHT CONCHI ILHADY MIX delivered 0012 Inch local aggregowand Portland come and water 0015 Exclude lives demande 0020 2000 pa 0100 2500 pa 0150 3000 pl 0200 3500 pel 0300 4000 pl 0.350 4500 pl 0400 5000 pe 0411 6000 pl 0412 8000 poi 0413 10.000 pel 0414 12.000 pl 1000 Fortugheally wength cemer, add 1010 Forucu gweight with regum id add 13.00 For we concrete het wel 1400 Forhol concrete cel add CY9150 CYM CY CY 9830 CY ho CY106 CY 11 CY27 CY 06 CY293 CY. 355 CY ON CYSOX CY 425 CY 98 Sol M 99 mo 100 100 111 122 206 233 055 101 103 103 110 113 116 122 129 227 220 425 105 480 1025 40 40 25 upan 465 03 30 Cast-In-Place Concrete 03 30 53 Miscellaneous Cast-In-Place Concrete 0010 CONCRETE IN PLACE 0020 Including forms (4 uses, tentoring the concrete, placement 0050 and finishing unless otherwise indicated 10300 Beams (3500 psl. 5 kip per LF. 10 span 0350 0500 Chimney foundation (5000 pindustrial, minimum 0510 Maximum 0700 Columns, que [4000 pu]. 12" x 17", minimum restoring 0720 Average reinforcing 0740 Msimum tortorcing 0900 16" 16.mum renforcing 0820 Average reinforcing 0840 Msimum Tortorcing 0900 24x24. minimum renorcing 0820 Average reinforcing 0940 Maximum renforcing 1000 36" 36" minimum reinforcing 1020 Average reinforcing Maximum erforcing 1100 Columns, round (4000 pul tied, 12" diameter, minimum reinforcing 1120 Average remorcing 1140 Maramum norcing 1200 16" diameter, minimum reinforcing 1220 Average reinforcing 1240 Maimum enorcing 1300 20 diameter, mentoring 1320 Average reinforcing 1340 Maximum tenforcing 1400 24" diameter,minum reinforcing Average reinforcing C14A CILA C14C C14C C1AA C14A CIU C14A CIUA CILA C144 CHLA C14A C14 CILA CHA CILA CILA CIA CILA CILA CILA CILA C14 CILA 15 62 12.804 CY 1291 18.55 10.782 CY 305 32.22 3.476 CY144 23.71 4.724CY. 168 11.96 167221 CY 325 10.13 19.743 CY510 903 22148 CY 770 16 22 12 330) CY 259 1257 15.911 CY. 435 10.25 19.512) CY. 675 23 66 8453 CY1221 1771 11.293 CY 390 14.15 14.134 CY 520 33695936 CY1197 23.328576CY. 345 17.82 11.223CY. 580 20 9795371 CY 285 15.27 13.088CY 470 12.11 16.515 CY 715 31.496351 CY262 19.12 10.460 CY 150 1377 14524 CY 675 41044.873 CY 254 24.058.316 CY 435 17.01 11.758 CY 675 51,853 857 CY: 248 27.06 7391 CY435 144 195 725 855 960 535 690 845 365 490 610 257 370 485 415 49 896 1 225 41 BI 1.100 73 288.73 380 99 363.99 485 64 1.114 1.550 75.50 1.440.50 1.975 B4.50 1 814 50 2.125 47 841 1,150 61 1.186 1600 7450159450 2.125 3250618 50 845 13 $23 1225 541.284 1.700 2250 47650 636 33 748 ses 43 1.108 1.425 36.50 73850990 SU 63 1.493 24.50 561 50 740 40 $45 1.250 58 50 1.380 90 12775 18 60 493 60 635 32 822 1.075 45 11 230 1.575 1475 12975 545 23 783 1.000 1040 1.00 715 455 630 211 360 510 167 320 1420 Daly Labor Outpur Hours Unit Bare Mal Bare Labor Bare Eque B T Crew 03 31 05 Normal Weight Structural Concrete 700010 PLACING CONCRETE 03 31 05 Normal Weight Structural Concrete Crew Daly Labor Dupu Hours Unit Bar Mak Bare Labor Bare 70 Bare Total Inch Total 70 OUP C20 C7 C20 C7 C20 C7 3475 CY C7 C20 C20 C7 C20 0010 PLACING CONCRETE 0020 Includes labor and equipment to place, strike off and consolidate 0050 Beams, elevated, smal beame, pumped 0100 Wshcrane and bucket 0200 Large beams, pumped 0250 With crane and bucket 0400 Columns, que or found 12" thick, pumped 0450 With cine and bucket 0600 18 thick, pumped 0650 Wihciane and bucket 0800 24" thick, pumped 0850 With crane and bucket 1000 36 thick, pumped 1050 With crane and bucket 1400 Elevated slabi, less than 5 thick, pumped 1450 With crane and bucket 15006" to 10 thick, pumped 1550 With crane and bucket 1600 Slabs over 10" thick, pumped 1650 With crane and bucket 1300 Footings, continuous shalow, direct chute 1950 Pumped 2000 Wih crane and bucket 2100 Footing, continuous, deep, direct chute 2150 Pumped 2200 With care and bucket 2400 Fookings, spread, under 1 CY, direct chute 2450 Pumped 2500 Wihcian and bucket 2600 Over 5 CY, direct chute 2650 Pumped 2700 Wah crane and bucket 2800 Foundation mat, over 20 CY. direct chute 2850 Pumped 3000 We crane and bucket 3200 Grade beams, direct chute 32.50 Pumped 3300 We crane and bucket 089988988098928988989898989898989898 C20 C7 45 90 65 50 40 90 55 92 70 140 100 140 95 160 110 180 130 120 150 90 140 160 110 55 65 45 120 150 100 350 400 300 150 180 120 1.067 CY 1.600 CY 711 CY 1.109 CY 1.067 CY 1.800 CY 711 1.309 CY 696 CY 1,029 CY 457 CY 720 CY 457 CY . 758 CY 400 CY 655 CY 356 CY 554 CY 400 CY 427 CY CY CY CY CY CY CY 1.600 CY CY . 720 CY CY 160 CY 240 CY CY 356 CY 600 CY 1310 52.10 5950 28.50 BE 26 8.75 41 19.65 60 65 39 13.10 52.10 67 32 99 25 8.75 34.75 48.50 23 71.50 25.50 8.55 3405 38 18 25 5625 16.80 560 22.40 27 1275 29.75 16.80 5.60 2240 28 13.45 41.45 14.70 499 1962 24.50 11.60 3610 13.10 437 170 20.50 9.85 30 35 14.30 39 1469 1570 525 20.96 29.50 1420 42.70 12.25 33 1258 14.70 4.92 1962 24.50 36.10 31 85 31.85 36 1210 48.10 59.50 28.50 88 14.30 39 14.89 15.70 525 2095 27 1275 28.75 491 13 504 5.90 197 8.90 426 13.16 11.45 31 11.76 1310 4.37 17.47 22 50 10.65 33.15 C20 74 135 49 99 48.50 78 31.50 54.50 31,50 57.50 28 30 24.50 42 22 30 50 50 19 ZB 50 48.50 68.50 121 22 30 5450 7.60 11.10 18 20 17.75 24 50 45.50 C6 C20 C C6 11.60 C20 C7 C20 C20 C7 C6 C20 C7 HVIS JEG R032110-10 Reinforcing Steel Weights and Measures Bar Designation No. Nominal Weight Lb/. Diameter Nominal Weight Perimeter 4 129 U.S. Customary Units Nominal Dimensions Cross Sectional Area, in 11 20 31 44 60 79 376 668 1,043 1.502 2044 2.670 3.000 4303 5313 7650 13.600 299 389 375 500 625 750 875 1.000 1128 1270 1.410 1693 2.257 Perimeter in. 1.178 1.571 1.963 2 356 2749 2.142 3544 3.990 4430 5320 7090 560 994 1.552 2.235 3,042 3973 5.059 Si Units Nominal Dimensions Diameter Cross Sectional Area, cm 9.52 .71 12.70 15.88 200 19.05 284 22.22 3.87 25.40 5.10 28.65 645 32.26 8.19 35.81 10:06 13.00 1452 5733 2581 100 9 10 11 127 1.56 225 4.00 598 698 798 900 1014 1125 1351 1801 7.906 11,384 20.238 18 DIVISION 015433 0241.31 - 34 0310 0320 0330 03 04 05 06 07 08 0920 0950, 0980 0960 0970, 0990 09 COVERS 21, 22, 23 26, 27, 3370 MF2010 MCKENZIE 382 MAT INST TOTAL 978 978 951 86,6 893 91.3 410 47.6 86.7 63.8 749 1024 61,0 86.6 98.4 543 109.2 49.9 73.2 90.8 88.5 90.0 83.2 58.0 89.6 50.2 74,0 922 46.7 80.7 873 379 52.5 84.1 37.9 53.5 97.3 41.6 81.3 94,6 53.4 69.6 979 41.1 66.6 100.0 30.3 855 97.1 70.8 862 96.4 68.3 81.4 96.3 62.1 81.1 CONTRACTOR EQUIPMENT SITE & INFRASTRUCTURE, DEMOLITION Concrete Forming & Accessones Concrete Reinforcing Castin Place Concrete CONCRETE MASONRY METALS WOOD, PLASTICS & COMPOSITES THERMAL & MOISTURE PROTECTION OPENINGS Plaster & Gypsum Board Celings & Acoustic Treatment Flooring Wall Finishes & Painting/Coating FINISHES DIVS. 10. 14, 25, 28, 41, 43, 44, 46 FIRE SUPPRESSION, PLUMBING & HVAC ELECTRICAL, COMMUNICATIONS & UTIL. WEIGHTED AVERAGE 39.2 TENNESSEE MEMPHIS NASHVILLE 375,380 - 391 370-372 MAT INST TOTAL MAT INST. TOTAL 1017 101.7 1048 1048 89.6 926 917 972 999 99.0 96.2 61.5 661 974 652 69.5 89.7 64.5 767 89.7 63.5 76.2 883 63.7 789 892 679 811 859 644 756 86.5 672 773 911 65.1 753 809 60.5 685 98.1 90.0 95.3 98.1 892 95.0 100.8 62,5 78.8 1061 66.4 833 88.4 65.6 79.3 922 63.3 B07 100,7 62.9 995 652 90.8 96.2 61.8 720 908 658 73.2 95.5 61.8 73.1 92.3 658 74.7 96.5 38.1 79.7 1023 679 96.7 56.4 723 1026 70.4 83.0 96.6 561 743 98.4 661 80.6 10010 80.8 $6.0 100.0 8! 6 962 99.9 71.2 87.9 998 759 89.8 100.3 66.4 82.3 100.9 63.3 809 966 70,3 84.9 96.7 727 859 91.1 INST 936 927 91.5 1086 NEW YORK DIVISION NEW YORK NIAGARA FALLS PLATTSBURGH POUGHKEEPSE 100.102 143 129 125 126 MAT INST TOTAL MAT CONTRACTOR EQUIPMENT INST TOTAL MAT TOTAL MAT 1148 1148 INST TOTAL 929 929 990 SITE & NFRASTRUCTURE, DEMOLITION 99.0 1154 1154 1331 1262 1284 942 93.4 87.3 102.5 Concrete Forming & Accessories 97.81173 108.7 1256 1876 1771 120 852 108.1 1050 919 824 8316 Concrete Reinforcing 1566 1028 182.3 143.7 100.1 96.3 1012 894 95.1 97.1 1336 Castin Place Concrete 1159 103.4 169,5 128.7 104.7 1024 103.8 94.3 926 978 1315 CONCRETE 110.7 1106 17821429 1084 102.5 1056 1023 87.6 963 1082 142.2 1244 MASONRY 1057 1739 1470 121.1 1154 889 883 8851017 1522 120.2 METALS 116.5 143.3 125.7 96.9 88.7 941 100.5 83.4 94.6 1045 1165 WOOD, PLASTICS & COMPOSITES 1078 192.2 156.2 846 97.7 93.5 80.5 86.1 87.0 1684 132.7 THERMAL & MOISTURE PROTECTION 107.7 165.0 130.4 103.6 102.1 103.0 1028 87.1 9661091 1419 1221 OPENINGS 92.6 180.7 1149 91.5 95.4 92.5 79.4 92.8 93.0 1523 108.0 Plaster & Gypsum Board 1175 194.6 1718 89.3 1074 1020 1199 192 912 958 1704 103 Ceilings & Acoustic Treatment 1081 1946 165.4 94.5 107.4 103.0 109.8 792 895 80:1 170.4 1400 Flooring 100.7 175.0 1220 88.4 107.6 94.0 1043 100.7 103.3 94.7 147.1 109.8 Wall Finishes & Painting/Coating 99.8 156,0 1339 945 102.5 99.3 110.6 77.0 902 113.6 1039 107.7 FINISHES 1112 1836 1512 923 108.2 1011 1019 852 1049 1517 13027 DIVS. 10-14, 25, 28, 41, 43, 44, 46 100.0 137.6 1078 100.0 100.8 1002 1000 51.6 899 100.0 1153 1032 FIRE SUPPRESSION, PLUMBING & HVAC 1002 166,0 127.6 946 92.4 93.7 949 814 892 94.9 1197 1052 ELECTRICAL, COMMUNICATIONS & UTIL 105.6 173.1 141.5 95.4 90,6 928 89.3 97.91182 1087 106.0 WEIGHTED AVERAGE 1663 133.0 98.3 98.0 932 975 85.0 91.9 100.713013 1140 015433 0241, 31-34 0310 0320 0330 03 04 05 06 07 08 0920 0950, 0980 0960 0970, 0990 09 COVERS 21, 22, 23 26, 27, 3370 MF2010 107.4 973 946 846

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts