Question: it's a supply chain management class and the question is here : A UAE-based chair manufacturing plant has forecasted demand for the upcoming 6 months

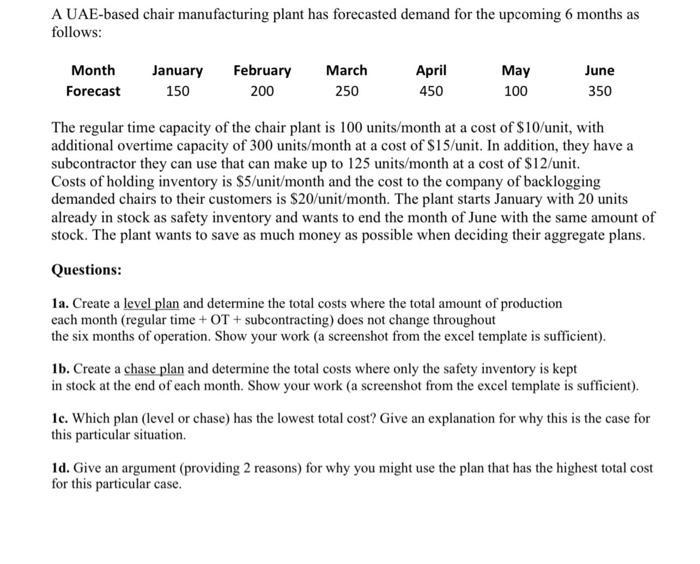

A UAE-based chair manufacturing plant has forecasted demand for the upcoming 6 months as follows: June Month Forecast January 150 February 200 March 250 April 450 May 100 350 The regular time capacity of the chair plant is 100 units/month at a cost of $10/unit, with additional overtime capacity of 300 units/month at a cost of $15/unit. In addition, they have a subcontractor they can use that can make up to 125 units/month at a cost of $12/unit. Costs of holding inventory is $5/unit/month and the cost to the company of backlogging demanded chairs to their customers is $20/unit/month. The plant starts January with 20 units already in stock as safety inventory and wants to end the month of June with the same amount of stock. The plant wants to save as much money as possible when deciding their aggregate plans. Questions: 1a. Create a level plan and determine the total costs where the total amount of production each month (regular time + OT + subcontracting) does not change throughout the six months of operation. Show your work (a screenshot from the excel template is sufficient). 1b. Create a chase plan and determine the total costs where only the safety inventory is kept in stock at the end of each month. Show your work (a screenshot from the excel template is sufficient). 1c. Which plan (level or chase) has the lowest total cost? Give an explanation for why this is the case for this particular situation. 1d. Give an argument (providing 2 reasons) for why you might use the plan that has the highest total cost for this particular case. A UAE-based chair manufacturing plant has forecasted demand for the upcoming 6 months as follows: June Month Forecast January 150 February 200 March 250 April 450 May 100 350 The regular time capacity of the chair plant is 100 units/month at a cost of $10/unit, with additional overtime capacity of 300 units/month at a cost of $15/unit. In addition, they have a subcontractor they can use that can make up to 125 units/month at a cost of $12/unit. Costs of holding inventory is $5/unit/month and the cost to the company of backlogging demanded chairs to their customers is $20/unit/month. The plant starts January with 20 units already in stock as safety inventory and wants to end the month of June with the same amount of stock. The plant wants to save as much money as possible when deciding their aggregate plans. Questions: 1a. Create a level plan and determine the total costs where the total amount of production each month (regular time + OT + subcontracting) does not change throughout the six months of operation. Show your work (a screenshot from the excel template is sufficient). 1b. Create a chase plan and determine the total costs where only the safety inventory is kept in stock at the end of each month. Show your work (a screenshot from the excel template is sufficient). 1c. Which plan (level or chase) has the lowest total cost? Give an explanation for why this is the case for this particular situation. 1d. Give an argument (providing 2 reasons) for why you might use the plan that has the highest total cost for this particular case

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts