Question: just need #8 please Case Part A: Tesla's Quality Challenge When Tesla announced the release of its new Model 3 electric car, over 276,000 people

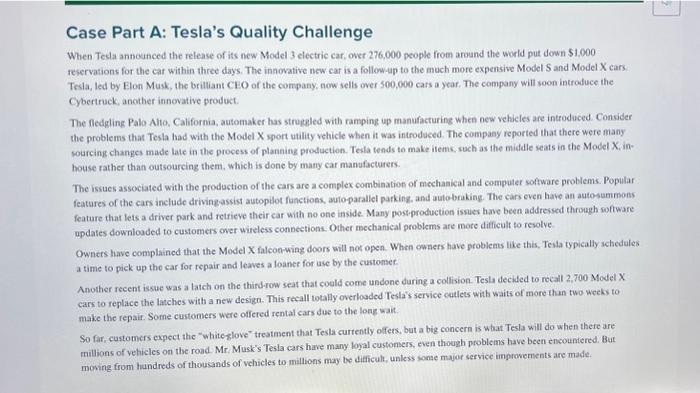

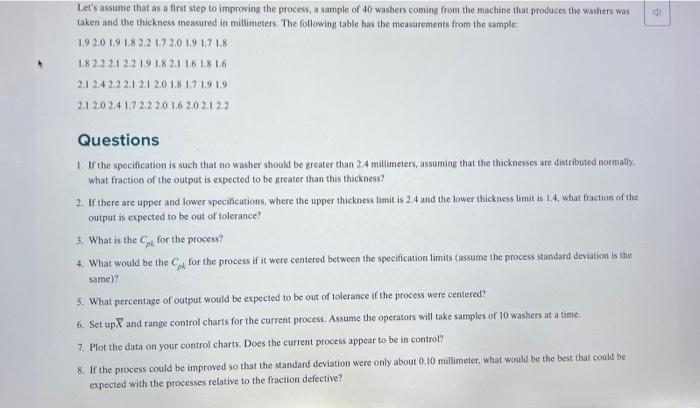

Case Part A: Tesla's Quality Challenge When Tesla announced the release of its new Model 3 electric car, over 276,000 people from around the world put down $1,000 reiervations for the cat within three days. The innovative new car is a follow ap to the much more expensive Model S and Model X cars. Tesla, led by Elon Musk, the brilliant CEO of the company; now sells over 500,000 cars a yrar. The company will soon introduce the Cybertruck, another innovative product. The fedgling Palo Alto, California, automaker has strogeled with ramping up manufacruring when new vehicles are introduced Consider the problems that Tesla had with the Model X wort utility vehicle when it was introduced. The company reported that there were many wourcing changes made late in the process of planaing production. Tesla tends to make irems, such as the middle seats in the Model X, inbouse rather than outsourcing them, which is done by many car manufucturers. The issues associated with the production of the cars are a complex combination of mechanical and computer software problems. Popular features of the cars include drivingassist autoplot fuactions, autoparallel parking, and autobraking. The cars even have an autosummons feature that lets a driver park and retrieve their car with no one inside. Many pospproduction issues have been addressed through software updates downloaded to customers over wireless conneetions. Other mechanical problems are more difficalt to resolve: Owners have complained that the Model X falcon-wing doors will nos open. When owners have probleats like this, Tesla typically webedules a time to pick up tho car for repair and leaves a loaner for ase by the customer. Another recent issue was a latch on the thirdiow seat that could come undone during a collision. Tesla decided to recall 2,700 Model X cars to replace the latches with a new design. This recall totally overloaded Tesla's service catlets with waits of more than two weeks to make the repair. Some customers were offered rental cars due to the long wait. So far, customers expect the "whiteglove treatment that Tesla curtently offers, but a big concern is what Tesla will do when there are millions of vehicles on the road. Mr. Musk's Tesla cars have many loyal custonsers, even though problems have been encountered. But mosing from handreds of thousands of vehicles to millions may be dificulh, unless sone major service improvements are made. Let's assume that as a first slep to improving the process, a sample of 40 washers coming from the machine that produces the waihers was taken and the thickness measured in millimeters. The following table has the measurements from the aample: 192.01.91.82.21.72.01.91.71.81.82.22.12.21.91.82.11.61.81.62.12.42.22.12.12.01.81.71.91.92.12.02.41.7222.01.62.02.12.2 Questions 1. If the specification is such that no washer should be greater than 2.4 millimeters, assuming that the thicknesses are distributed normally, what fraction of the output is expected to be greater than this thickness? 2. If there are upper and lower specifieations, where the upper thickness limit is 2.4 and the lower thickness limit is 1.4, what fraction of the output is expected to be out of tolerance? 3. What is the Cpk for the process? 4. What would be the Cph for the process if it were centered between the specification limits (assume the process standard deviation is the same)? 5. What percentage of output would be expected to be out of tolerance if the process were centered? 6. Set up X and range control charts for the current process. Assume the operators will take samples of 10 washers at a time. 7. Plot the data on your control charts. Does the current process appear to be in control? 8. If the process cosild be improved so that the standard deviation were only about 0.10 millimeter, what would be the best that could be expected with the processes relative to the fraction defective

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts