Question: - Key issue/problem statement what is the key problem/s or issue/s addressed in the case? What is the main decision that manager/s need to make?

- Key issue/problem statement what is the key problem/s or issue/s addressed in the case? What is the main decision that manager/s need to make? Maximum = 2 issues. - Options with pros and cons identified what are the options for resolving the key problems/issues? What are the major pros and cons with each options? Maximum = 3 options.

- Recommendations what is your advice for managers regarding problem/issues raised? (i.e., provide definite, succinct, clearly explained practical recommendations). Maximum = 2 recommendations.

Key takeaways what are the lessons for supply chain managers? (i.e., after reading this article/question/case, I learned that ?) Maximum = 2 lessons.

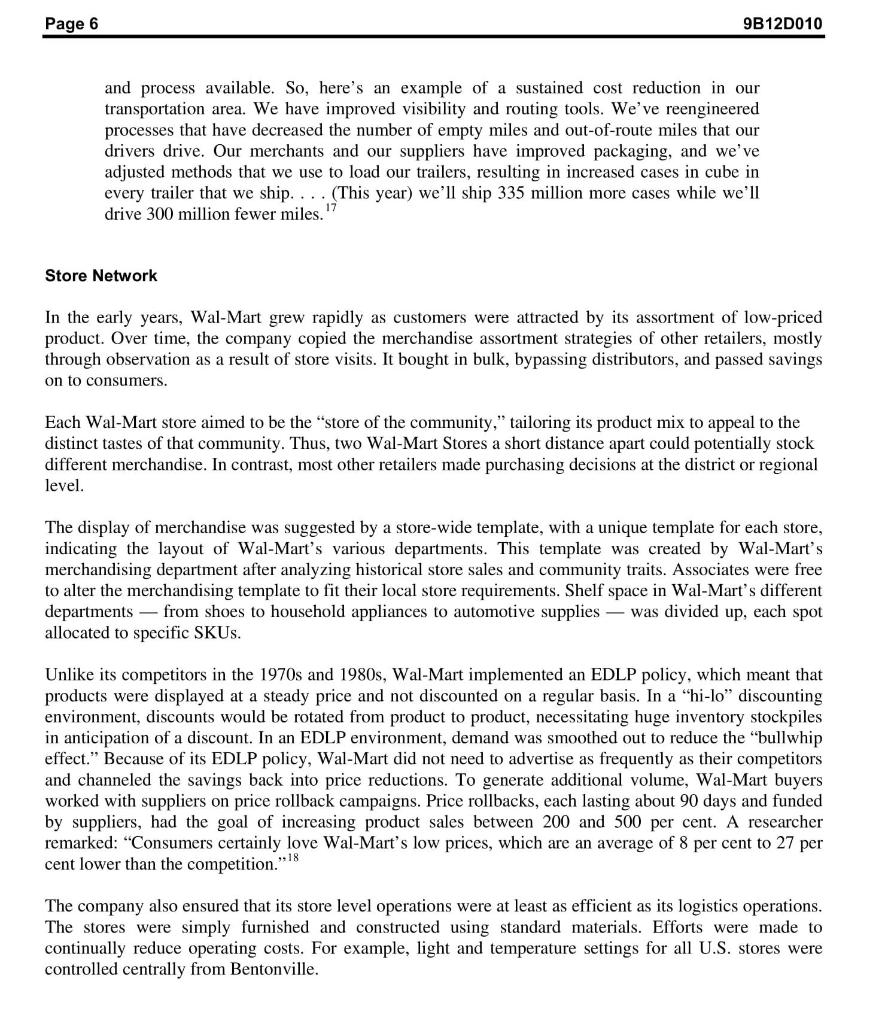

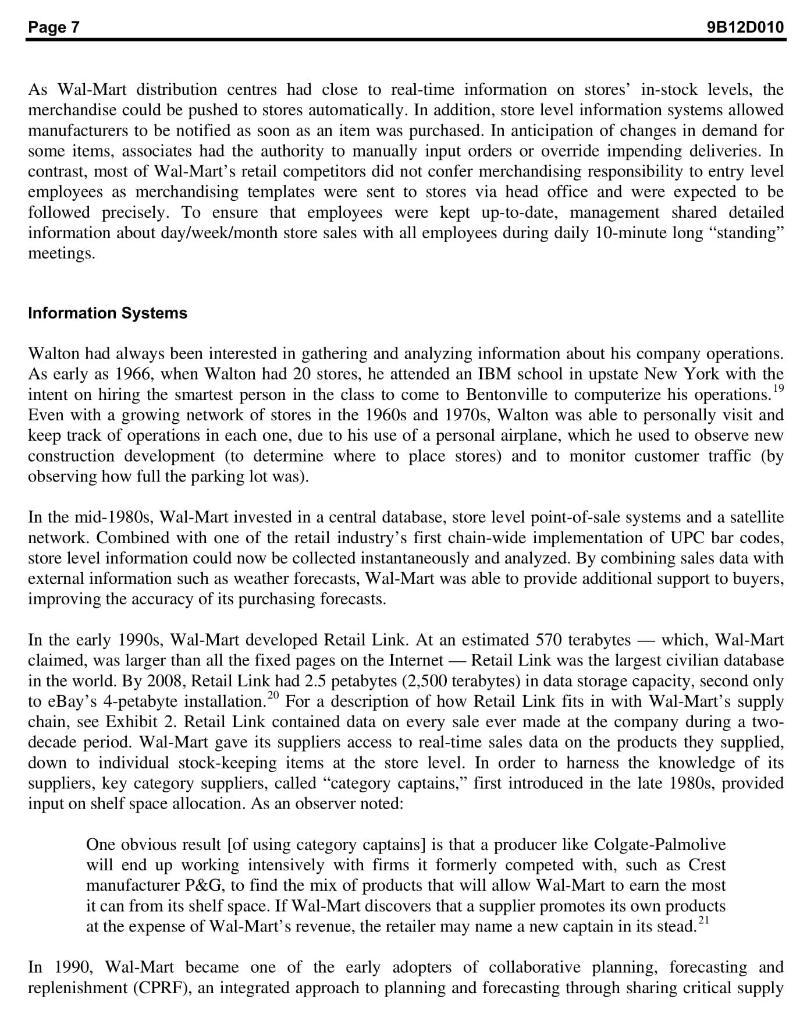

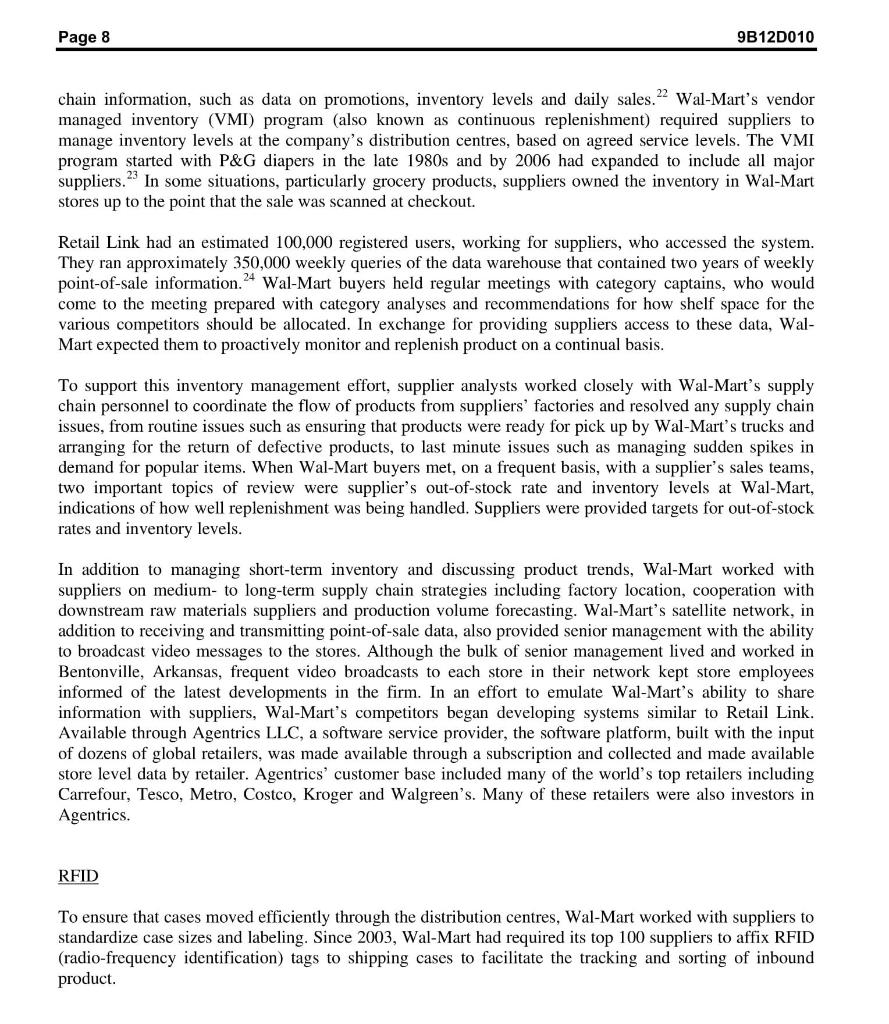

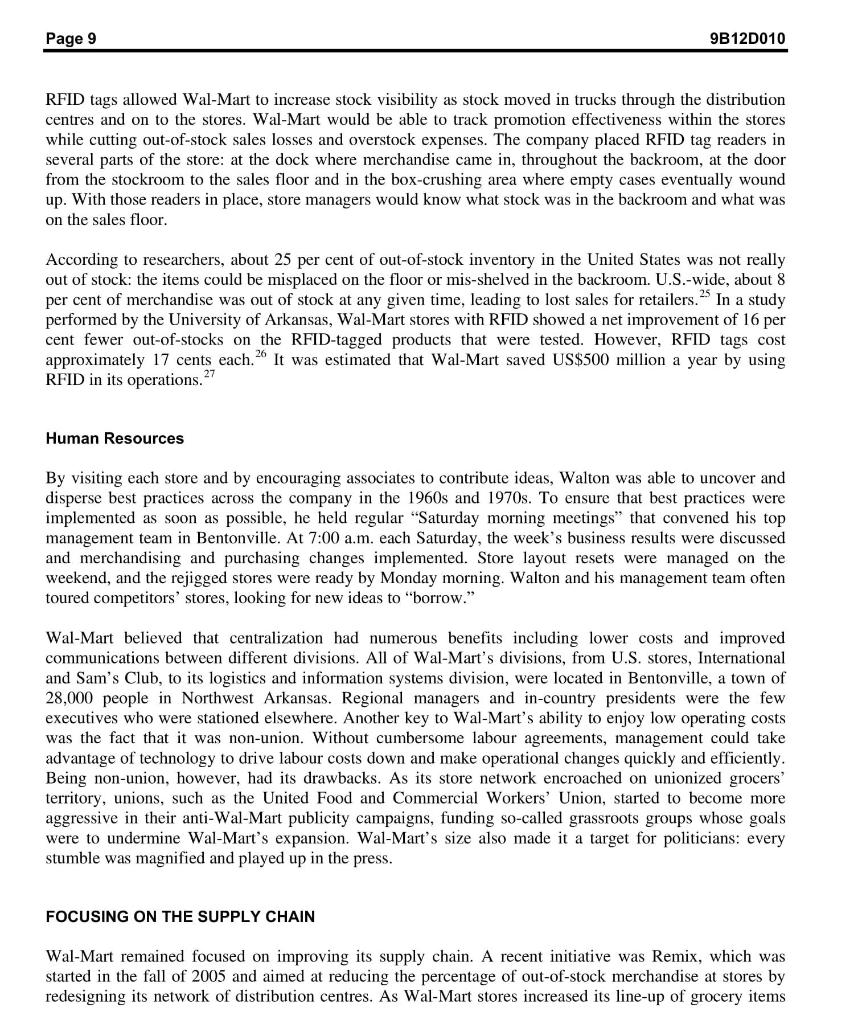

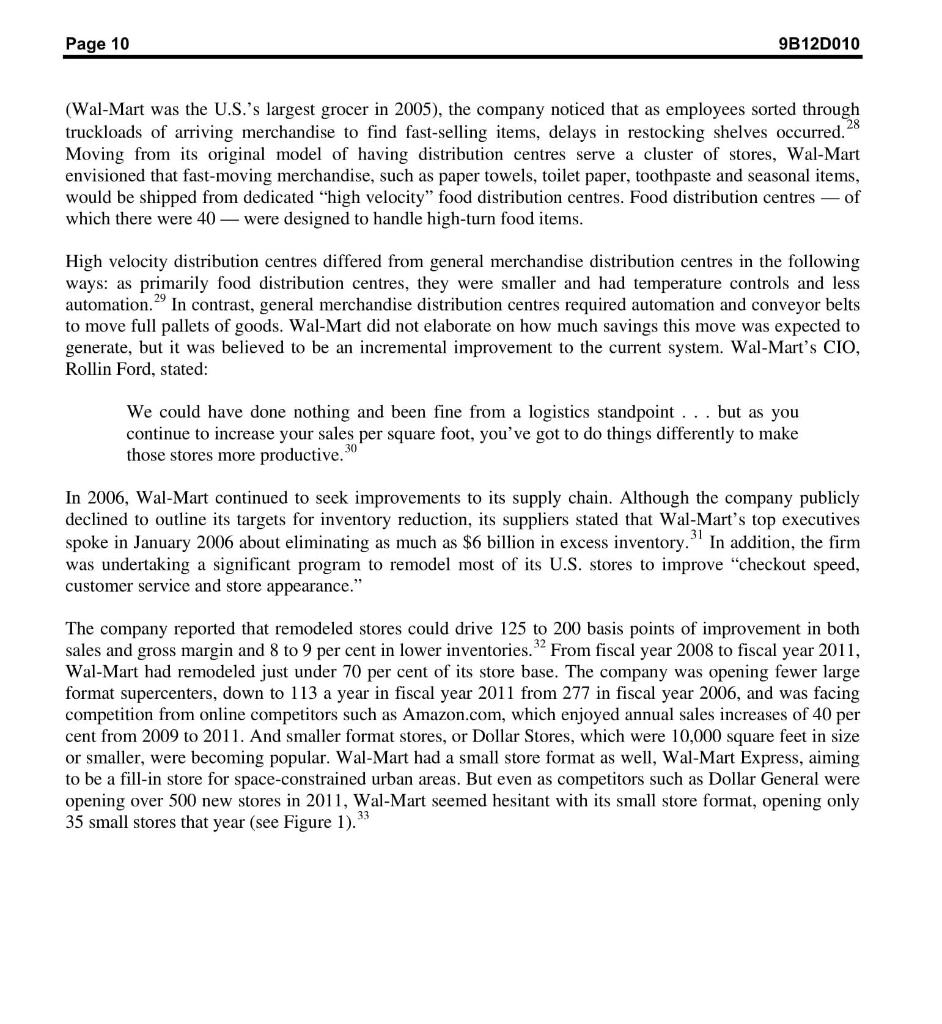

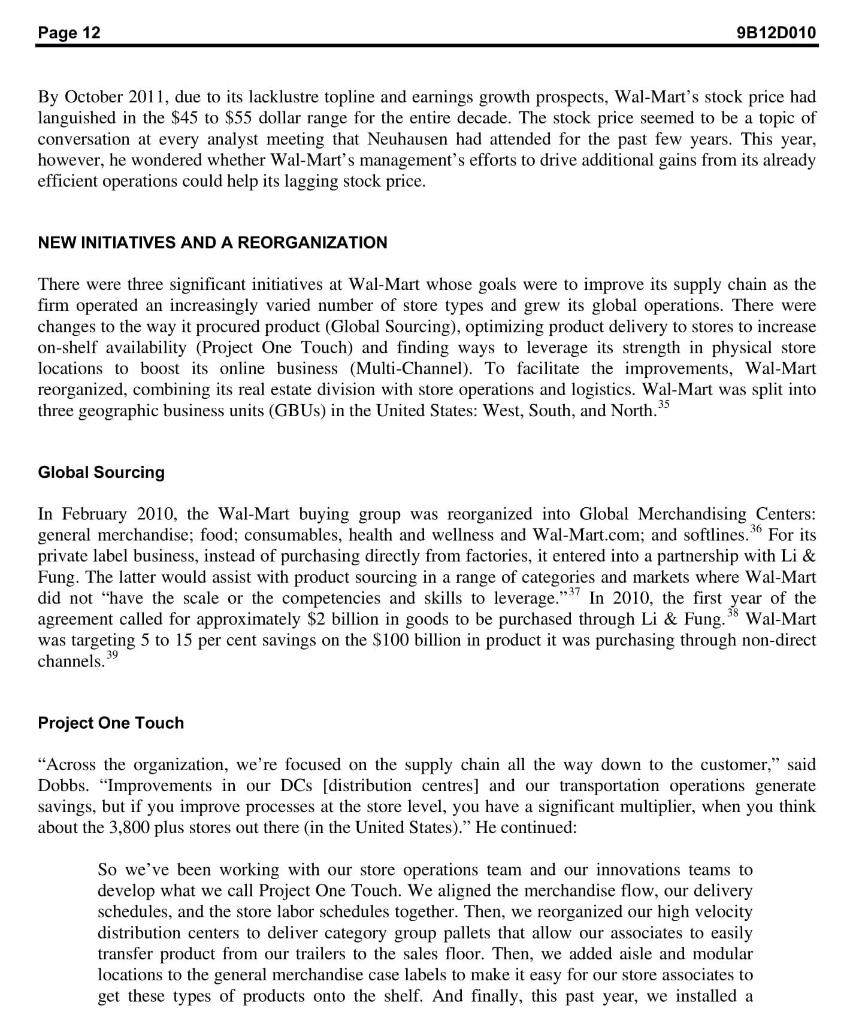

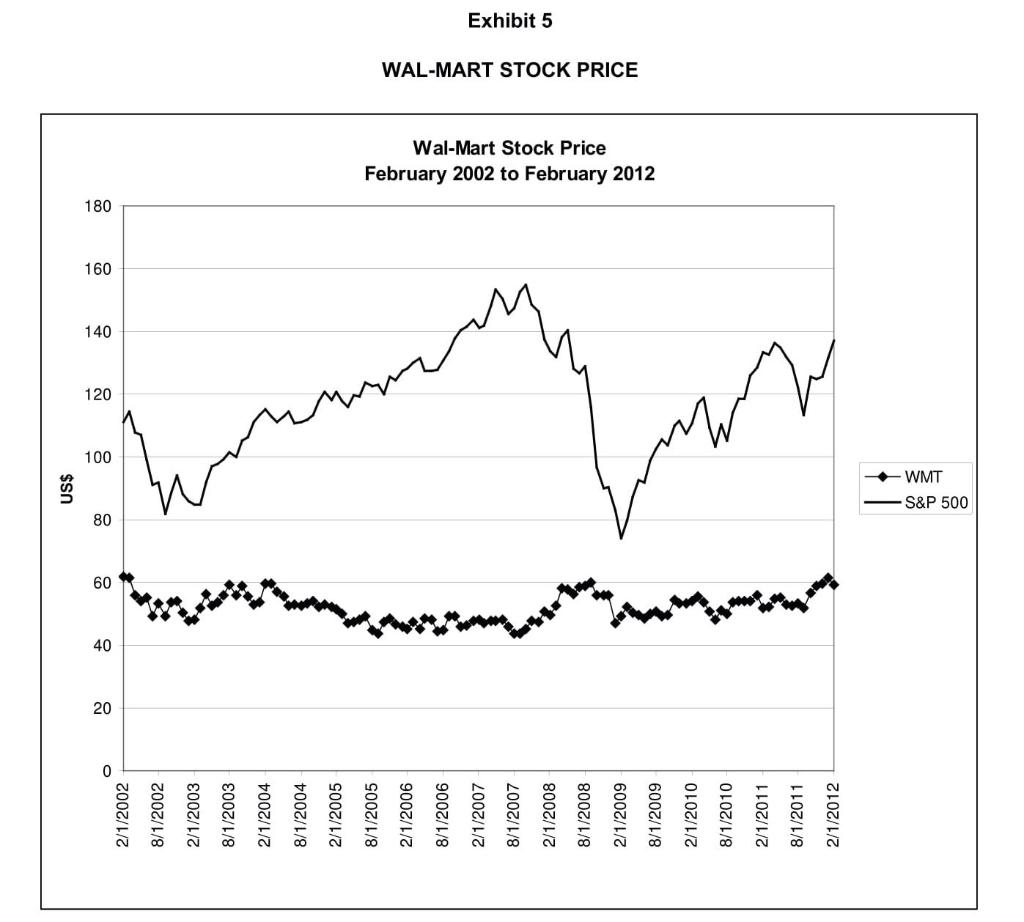

Page 5 9B12D010 Distribution Wal-Mart's store openings were driven directly by its distribution strategy. Because its first distribution centre was a significant investment for the firm, Walton insisted on saturating the area within a day's driving distance in order to gain economies of scale. Over the years, competitors had copied this hub-and- spoke" design of high volume distribution centres serving a cluster of stores. This distribution-led store expansion strategy persisted for the next two decades as Wal-Mart added thousands of U.S. stores, expanding across the nation from its headquarters in Arkansas. Stores were located in low-rent, suburban areas close to major highways. In contrast, key competitor Kmart's stores were thinly spread throughout the U.S. and located in prime urban areas. By the time the rest of the retail industry started to take notice of Wal-Mart in the 1980s, it had built up the most efficient logistics network of any retailer. Wal-Mart's 75,000-person logistics and its information systems division included the largest private truck fleet employee base of any firm 6,600 trucks and 55,000 trailers, which delivered the majority of merchandise sold at stores." Its 150 distribution centres, located throughout the United States, were a mix of general merchandise, food and soft goods (clothing) distribution centres, processing over five billion cases a year through its entire network. In the United States, Wal-Mart's distribution centres received about 315,000 inbound truckloads, of which 115,000 were shipped "collect, which meant they were picked up directly from suppliers' warehouses by Wal-Mart's trucking fleet, The remaining 200,000 loads were shipped by suppliers' trucks or by logistics providers. The goal at Wal-Mart's distribution centres was for high turning items - such as fresh food or other perishable merchandise to be cross-docked, or directly transferred from inbound to outbound trailers without extra storage. The average distance from distribution centre to stores was approximately 130 miles. Each of these distribution centres were profiled in a store friendly way, with similar products stacked together. Merchandise purchased directly from factories in offshore locations such as China or India were processed at coastal distribution centres before shipment to U.S. stores. On the way back from delivering product to stores, Wal-Mart's trucks generated "backhaul" revenue by transporting unsold merchandise on trucks that would be otherwise empty. Wal-Mart's backhaul revenues its private fleet operated as a for-hire carrier when it was not busy transporting merchandise from distribution centres to stores were more than US$1 billion per year. In mid-2010, Wal-Mart was looking to expand its backhaul program, to pick up more product directly from suppliers' factories. It was seeking, in some cases, a 6 per cent reduction in the manufacturer's selling price. For perspective, suppliers estimated the actual transportation expense was just 3 per cent of the selling price." 16 Because their trucking employees were non-unionized and in-house, Wal-Mart was able to implement and improve upon standard delivery procedures, coordinating and deploying the entire fleet as necessary. Uniform operating standards ensured that miscommunication between traffic coordinators, truckers and store level employees were minimized. During an analyst meeting in October 2011, Johnnie Dobbs, Wal- Mart Stores' (Wal-Mart's) EVP Logistics, had stated: Everyday low cost is the foundation for everyday low prices. So our focus across the organization is delivering products that our customers need in the most efficient method Page 6 9B12D010 and process available. So, here's an example of a sustained cost reduction in our transportation area. We have improved visibility and routing tools. We've reengineered processes that have decreased the number of empty miles and out-of-route miles that our drivers drive. Our merchants and our suppliers have improved packaging, and we've adjusted methods that we use to load our trailers, resulting in increased cases in cube in every trailer that we ship. . . . (This year) we'll ship 335 million more cases while we'll drive 300 million fewer miles. 17 Store Network In the early years, Wal-Mart grew rapidly as customers were attracted by its assortment of low-priced product. Over time, the company copied the merchandise assortment strategies of other retailers, mostly through observation as a result of store visits. It bought in bulk, bypassing distributors, and passed savings on to consumers. Each Wal-Mart store aimed to be the store of the community," tailoring its product mix to appeal to the distinct tastes of that community. Thus, two Wal-Mart Stores a short distance apart could potentially stock different merchandise. In contrast, most other retailers made purchasing decisions at the district or regional level. The display of merchandise was suggested by a store-wide template, with a unique template for each store, indicating the layout of Wal-Mart's various departments. This template was created by Wal-Mart's merchandising department after analyzing historical store sales and community traits. Associates were free to alter the merchandising template to fit their local store requirements. Shelf space in Wal-Mart's different departments from shoes to household appliances to automotive supplies was divided up, each spot allocated to specific SKUs. Unlike its competitors in the 1970s and 1980s, Wal-Mart implemented an EDLP policy, which meant that products were displayed at a steady price and not discounted on a regular basis. In a "hi-lo" discounting environment, discounts would be rotated from product to product, necessitating huge inventory stockpiles in anticipation of a discount. In an EDLP environment, demand was smoothed out to reduce the "bullwhip effect." Because of its EDLP policy, Wal-Mart did not need to advertise as frequently as their competitors and channeled the savings back into price reductions. To generate additional volume, Wal-Mart buyers worked with suppliers on price rollback campaigns. Price rollbacks, each lasting about 90 days and funded by suppliers, had the goal of increasing product sales between 200 and 500 per cent. A researcher remarked: "Consumers certainly love Wal-Mart's low prices, which are an average of 8 per cent to 27 per cent lower than the competition."18 The company also ensured that its store level operations were at least as efficient as its logistics operations. The stores were simply furnished and constructed using standard materials. Efforts were made to continually reduce operating costs. For example, light and temperature settings for all U.S. stores were controlled centrally from Bentonville. Page 7 9B12D010 As Wal-Mart distribution centres had close to real-time information on stores in-stock levels, the merchandise could be pushed to stores automatically. In addition, store level information systems allowed manufacturers to be notified as soon as an item was purchased. In anticipation of changes in demand for some items, associates had the authority to manually input orders or override impending deliveries. In contrast, most of Wal-Mart's retail competitors did not confer merchandising responsibility to entry level employees as merchandising templates were sent to stores via head office and were expected to be followed precisely. To ensure that employees were kept up-to-date, management shared detailed information about day/week/month store sales with all employees during daily 10-minute long "standing" meetings. Information Systems Walton had always been interested in gathering and analyzing information about his company operations. As early as 1966, when Walton had 20 stores, he attended an IBM school in upstate New York with the intent on hiring the smartest person in the class to come to Bentonville to computerize his operations." Even with a growing network of stores in the 1960s and 1970s, Walton was able to personally visit and keep track of operations in each one, due to his use of a personal airplane, which he used to observe new construction development (to determine where to place stores) and to monitor customer traffic (by observing how full the parking lot was). In the mid-1980s, Wal-Mart invested in a central database, store level point-of-sale systems and a satellite network. Combined with one of the retail industry's first chain-wide implementation of UPC bar codes, store level information could now be collected instantaneously and analyzed. By combining sales data with external information such as weather forecasts, Wal-Mart was able to provide additional support to buyers, improving the accuracy of its purchasing forecasts. In the early 1990s, Wal-Mart developed Retail Link. At an estimated 570 terabytes which, Wal-Mart claimed, was larger than all the fixed pages on the Internet - Retail Link was the largest civilian database in the world. By 2008, Retail Link had 2.5 petabytes (2,500 terabytes) in data storage capacity, second only to eBay's 4-petabyte installation. For a description of how Retail Link fits in with Wal-Mart's supply chain, see Exhibit 2. Retail Link contained data on every sale ever made at the company during a two- decade period. Wal-Mart gave its suppliers access to real-time sales data on the products they supplied, down to individual stock-keeping items at the store level. In order to harness the knowledge of its suppliers, key category suppliers, called "category captains," first introduced in the late 1980s, provided input on shelf space allocation. As an observer noted: One obvious result [of using category captains) is that a producer like Colgate-Palmolive will end up working intensively with firms it formerly competed with, such as Crest manufacturer P&G, to find the mix of products that will allow Wal-Mart to earn the most it can from its shelf space. If Wal- Mart discovers that a supplier promotes its own products at the expense of Wal-Mart's revenue, the retailer may name a new captain in its stead. 21 In 1990, Wal-Mart became one of the early adopters of collaborative planning, forecasting and replenishment (CPRF), an integrated approach to planning and forecasting through sharing critical supply Page 8 9B12D010 chain information, such as data on promotions, inventory levels and daily sales. Wal-Mart's vendor managed inventory (VMI) program (also known as continuous replenishment) required suppliers to manage inventory levels at the company's distribution centres, based on agreed service levels. The VMI program started with P&G diapers in the late 1980s and by 2006 had expanded to include all major In some situations, particularly grocery products, suppliers owned the inventory in Wal-Mart stores up to the point that the sale was scanned at checkout. suppliers.23 Retail Link had an estimated 100,000 registered users, working for suppliers, who accessed the system. They ran approximately 350,000 weekly queries of the data warehouse that contained two years of weekly point-of-sale information. * Wal-Mart buyers held regular meetings with category captains, who would come to the meeting prepared with category analyses and recommendations for how shelf space for the various competitors should be allocated. In exchange for providing suppliers access to these data, Wal- Mart expected them to proactively monitor and replenish product on a continual basis. To support this inventory management effort, supplier analysts worked closely with Wal-Mart's supply chain personnel to coordinate the flow of products from suppliers' factories and resolved any supply chain issues, from routine issues such as ensuring that products were ready for pick up by Wal-Mart's trucks and arranging for the return of defective products, to last minute issues such as managing sudden spikes in demand for popular items. When Wal-Mart buyers met, on a frequent basis, with a supplier's sales teams, two important topics of review were supplier's out-of-stock rate and inventory levels at Wal-Mart, indications of how well replenishment was being handled. Suppliers were provided targets for out-of-stock rates and inventory levels. In addition to managing short-term inventory and discussing product trends, Wal-Mart worked with suppliers on medium- to long-term supply chain strategies including factory location, cooperation with downstream raw materials suppliers and production volume forecasting. Wal-Mart's satellite network, in addition to receiving and transmitting point-of-sale data, also provided senior management with the ability to broadcast video messages to the stores. Although the bulk of senior management lived and worked in Bentonville, Arkansas, frequent video broadcasts to each store in their network kept store employees informed of the latest developments in the firm. In an effort to emulate Wal-Mart's ability to share information with suppliers, Wal-Mart's competitors began developing systems similar to Retail Link. Available through Agentrics LLC, a software service provider, the software platform, built with the input of dozens of global retailers, was made available through a subscription and collected and made available store level data by retailer. Agentrics' customer base included many of the world's top retailers including Carrefour, Tesco, Metro, Costco, Kroger and Walgreen's. Many of these retailers were also investors in Agentrics. RFID To ensure that cases moved efficiently through the distribution centres, Wal-Mart worked with suppliers to standardize case sizes and labeling. Since 2003, Wal-Mart had required its top 100 suppliers to affix RFID (radio-frequency identification) tags to shipping cases to facilitate the tracking and sorting of inbound product. Page 9 9B12D010 RFID tags allowed Wal-Mart to increase stock visibility as stock moved in trucks through the distribution centres and on to the stores. Wal-Mart would be able to track promotion effectiveness within the stores while cutting out-of-stock sales losses and overstock expenses. The company placed RFID tag readers in several parts of the store: at the dock where merchandise came in, throughout the backroom, at the door from the stockroom to the sales floor and in the box-crushing area where empty cases eventually wound up. With those readers in place, store managers would know what stock was in the backroom and what was on the sales floor. According to researchers, about 25 per cent of out-of-stock inventory in the United States was not really out of stock: the items could be misplaced on the floor or mis-shelved in the backroom. U.S.-wide, about 8 per cent of merchandise was out of stock at any given time, leading to lost sales for retailers. In a study performed by the University of Arkansas, Wal-Mart stores with RFID showed a net improvement of 16 per cent fewer out-of-stocks on the RFID-tagged products that were tested. However, RFID tags cost approximately 17 cents each.26 It was estimated that Wal-Mart saved US$500 million a year by using RFID in its operations.27 Human Resources By visiting each store and by encouraging associates to contribute ideas, Walton was able to uncover and disperse best practices across the company in the 1960s and 1970s. To ensure that best practices were implemented as soon as possible, he held regular "Saturday morning meetings" that convened his top management team in Bentonville. At 7:00 a.m. each Saturday, the week's business results were discussed and merchandising and purchasing changes implemented. Store layout resets were managed on the weekend, and the rejigged stores were ready by Monday morning. Walton and his management team often toured competitors' stores, looking for new ideas to "borrow." Wal-Mart believed that centralization had numerous benefits including lower costs and improved communications between different divisions. All of Wal-Mart's divisions, from U.S. stores, International and Sam's Club, to its logistics and information systems division, were located in Bentonville, a town of 28,000 people in Northwest Arkansas. Regional managers and in-country presidents were the few executives who were stationed elsewhere. Another key to Wal-Mart's ability to enjoy low operating costs was the fact that it was non-union. Without cumbersome labour agreements, management could take advantage of technology to drive labour costs down and make operational changes quickly and efficiently. Being non-union, however, had its drawbacks. As its store network encroached on unionized grocers' territory, unions, such as the United Food and Commercial Workers' Union, started to become more aggressive in their anti-Wal-Mart publicity campaigns, funding so-called grassroots groups whose goals were to undermine Wal-Mart's expansion. Wal-Mart's size also made it a target for politicians: every stumble was magnified and played up in the press. FOCUSING ON THE SUPPLY CHAIN Wal-Mart remained focused on improving its supply chain. A recent initiative was Remix, which was started in the fall of 2005 and aimed at reducing the percentage of out-of-stock merchandise at stores by redesigning its network of distribution centres. As Wal-Mart stores increased its line-up of grocery items Page 10 9B12D010 28 (Wal-Mart was the U.S.'s largest grocer in 2005), the company noticed that as employees sorted through truckloads of arriving merchandise to find fast-selling items, delays in restocking shelves occurred. Moving from its original model of having distribution centres serve a cluster of stores, Wal-Mart envisioned that fast-moving merchandise, such as paper towels, toilet paper, toothpaste and seasonal items, would be shipped from dedicated "high velocity" food distribution centres. Food distribution centres - of which there were 40 were designed to handle high-turn food items. High velocity distribution centres differed from general merchandise distribution centres in the following ways: as primarily food distribution centres, they were smaller and had temperature controls and less automation. In contrast, general merchandise distribution centres required automation and conveyor belts to move full pallets of goods. Wal-Mart did not elaborate on how much savings this move was expected to generate, but it was believed to be an incremental improvement to the current system. Wal-Mart's CIO, Rollin Ford, stated: We could have done nothing and been fine from a logistics standpoint ... but as you continue to increase your sales per square foot, you've got to do things differently to make those stores more productive." In 2006, Wal-Mart continued to seek improvements to its supply chain. Although the company publicly declined to outline its targets for inventory reduction, its suppliers stated that Wal-Mart's top executives spoke in January 2006 about eliminating as much as $6 billion in excess inventory." In addition, the firm was undertaking a significant program to remodel most of its U.S. stores to improve "checkout speed, customer service and store appearance." The company reported that remodeled stores could drive 125 to 200 basis points of improvement in both sales and gross margin and 8 to 9 per cent in lower inventories. From fiscal year 2008 to fiscal year 2011, Wal-Mart had remodeled just under 70 per cent of its store base. The company was opening fewer large format supercenters, down to 113 a year in fiscal year 2011 from 277 in fiscal year 2006, and was facing competition from online competitors such as Amazon.com, which enjoyed annual sales increases of 40 per cent from 2009 to 2011. And smaller format stores, or Dollar Stores, which were 10,000 square feet in size or smaller, were becoming popular. Wal-Mart had a small store format as well, Wal-Mart Express, aiming to be a fill-in store for space-constrained urban areas. But even as competitors such as Dollar General were opening over 500 new stores in 2011, Wal-Mart seemed hesitant with its small store format, opening only 35 small stores that year (see Figure 1). 33 Page 11 9B12D010 Figure 1: Net New Small Store Plans - FY 2011 600 565 500 400 300 240 200 190 150 100 45 35 12 0 Dollar General Dollar Tree Walgreens CVS Big Lots Wal-Mart Fred's But execution issues at the store level and disruption from the remodeling had a negative impact on Wal- Mart's sales. There was also the financial crisis that started in 2008, along with a cutback on staffing levels. The result was nine consecutive quarters of same store sales decline starting in the second quarter of 2009. 34 Figure 2: Wal-Mart Same Store Sales Increases (Decreases) 5.0% 4.4% 4.0% 3.6% 3.0% 2.8% 2.6% 2.4% 2.2% 1.9% 2.0% 1.0% 0.0% 1008 2008 3008 4008 1009 3Q11 4011 -0.5% -1.0% -1.5% -0.9% -1.1% -1.4% -1.3% -1.8% -1.8% -2.0% -2.0% -3.0% Page 12 9B12D010 By October 2011, due to its lacklustre topline and earnings growth prospects, Wal-Mart's stock price had languished in the $45 to $55 dollar range for the entire decade. The stock price seemed to be a topic of conversation at every analyst meeting that Neuhausen had attended for the past few years. This year, however, he wondered whether Wal-Mart's management's efforts to drive additional gains from its already efficient operations could help its lagging stock price. NEW INITIATIVES AND A REORGANIZATION There were three significant initiatives at Wal-Mart whose goals were to improve its supply chain as the firm operated an increasingly varied number of store types and grew its global operations. There were changes to the way it procured product (Global Sourcing), optimizing product delivery to stores to increase on-shelf availability (Project One Touch) and finding ways to leverage its strength in physical store locations to boost its online business (Multi-Channel). To facilitate the improvements, Wal-Mart reorganized, combining its real estate division with store operations and logistics. Wal-Mart was split into three geographic business units (GBUs) in the United States: West, South, and North.35 Global Sourcing In February 2010, the Wal-Mart buying group was reorganized into Global Merchandising Centers: general merchandise; food; consumables, health and wellness and Wal-Mart.com; and softlines. For its private label business, instead of purchasing directly from factories, it entered into a partnership with Li & Fung. The latter would assist with product sourcing in a range of categories and markets where Wal-Mart did not have the scale or the competencies and skills to leverage."?? In 2010, the first year of the agreement called for approximately $2 billion in goods to be purchased through Li & Fung. Wal-Mart was targeting 5 to 15 per cent savings on the $100 billion in product it was purchasing through non-direct channels. 39 Project One Touch "Across the organization, we're focused on the supply chain all the way down to the customer," said Dobbs. "Improvements in our DCs [distribution centres] and our transportation operations generate savings, but if you improve processes at the store level, you have a significant multiplier, when you think about the 3,800 plus stores out there in the United States)." He continued: So we've been working with our store operations team and our innovations teams to develop what we call Project One Touch. We aligned the merchandise flow, our delivery schedules, and the store labor schedules together. Then, we reorganized our high velocity distribution centers to deliver category group pallets that allow our associates to easily transfer product from our trailers to the sales floor. Then, we added aisle and modular locations to the general merchandise case labels to make it easy for our store associates to get these types of products onto the shelf. And finally, this past year, we installed a Exhibit 5 WAL-MART STOCK PRICE Wal-Mart Stock Price February 2002 to February 2012 180 160 140 120 100 US$ WMT S&P 500 80 40 20 2/1/2002 8/1/2002 2/1/2003 8/1/2003 2/1/2004 8/1/2004 2/1/2005 8/1/2005 2/1/2006 8/1/2006 2/1/2007 8/1/2007 2/1/2008 8/1/2008 2/1/2009 8/1/2009 2/1/2010 8/1/2010 2/1/2011 8/1/2011 2/1/2012Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts