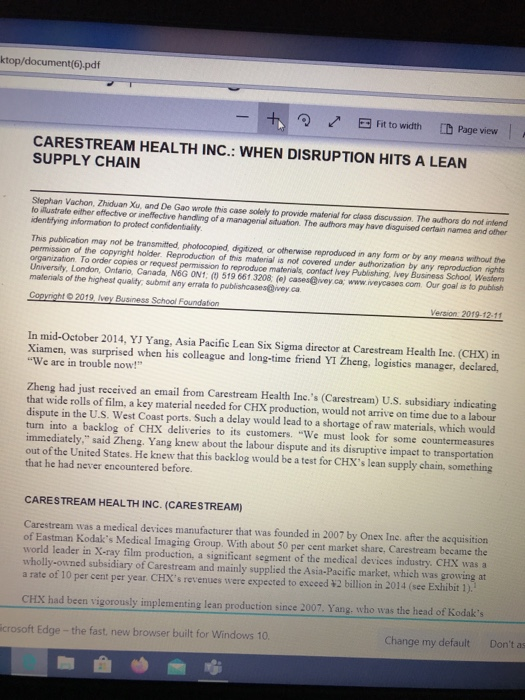

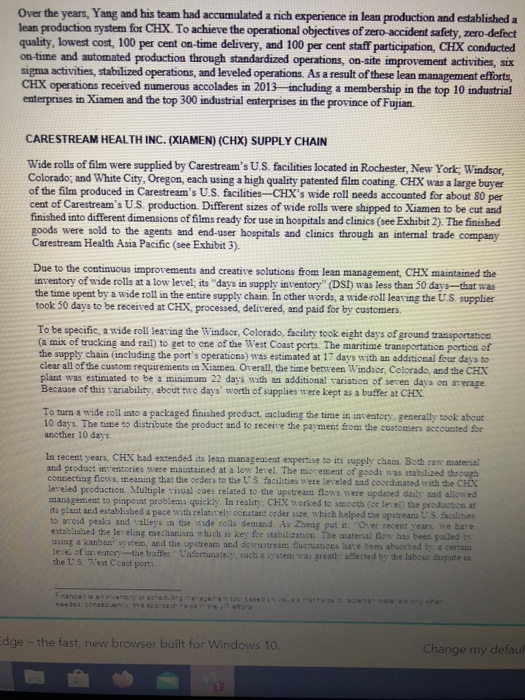

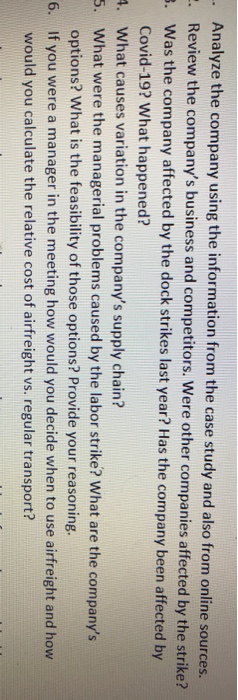

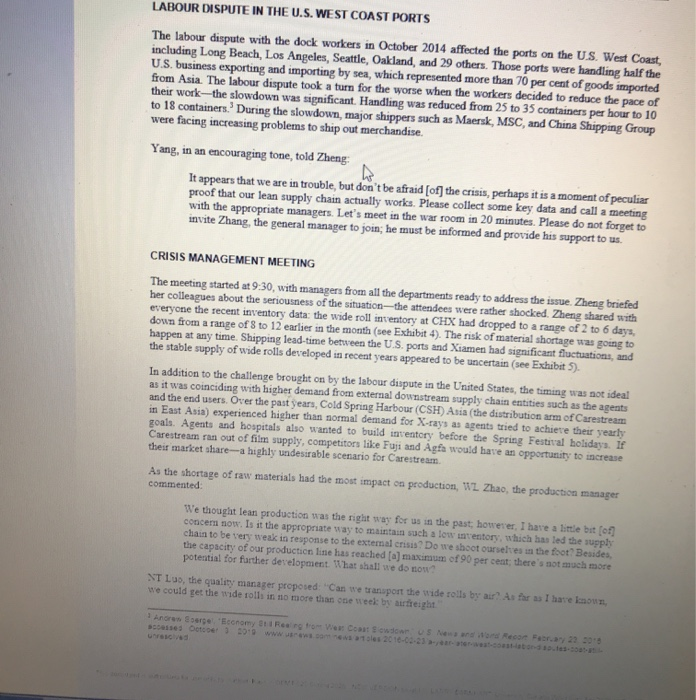

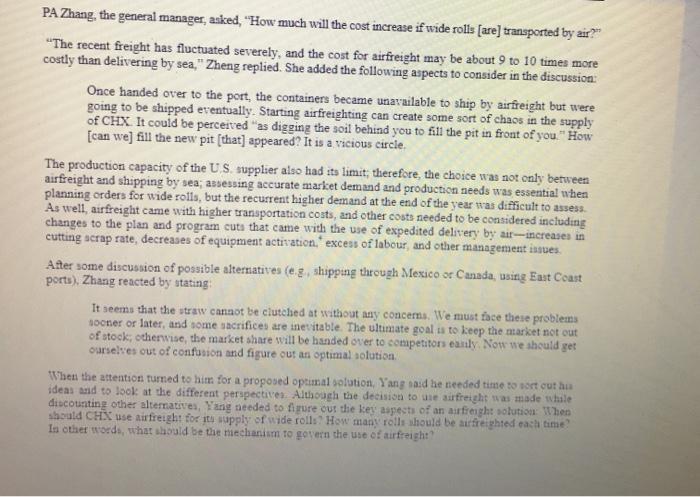

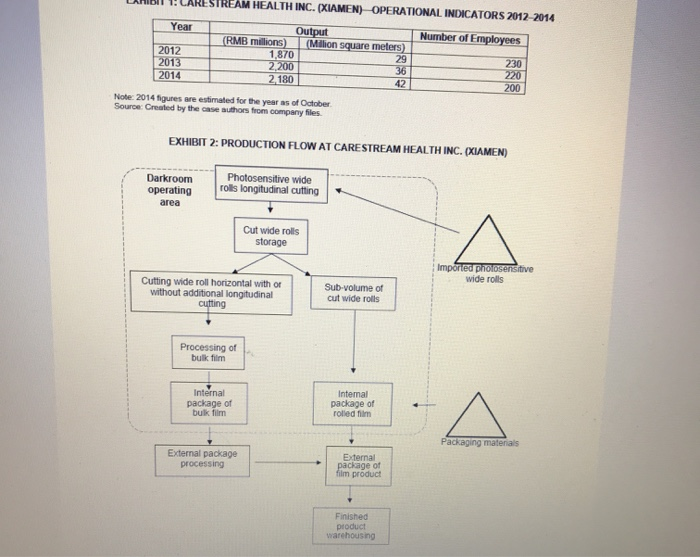

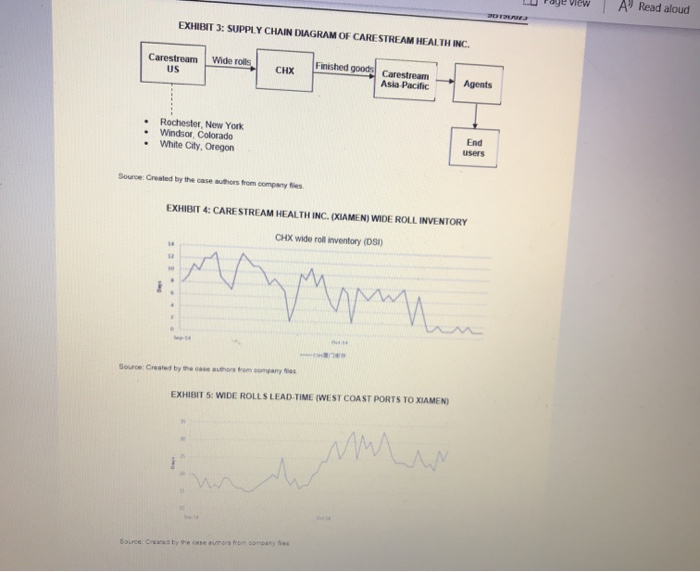

ktop/document(6).pdf Fit to width Page view CARESTREAM HEALTH INC.: WHEN DISRUPTION HITS A LEAN SUPPLY CHAIN Stephan Vachon Zhiduan Xu, and De Gao wrote this case solely to provide material for class discussion. The authors do not intend to slustrate the effective or ineffective handling of a managerial situation. The authors may have disguised certain names and other identifying information to protect confidentiality This publication may not be transmitted, photocopied, digitized or otherwise reproduced in any form or by any means without the permission of the copyright holder. Reproduction of this material is not covered under authorization by any reproduction rights organization. To order copies or request permission to reproduce materials contact Ivey Publishing. Ivey Business School Western University, London, Ontario, Canada, NOG ONT (9 519 661 3208(e) cases@veyca www.iveycases.com Our goal is to publish materials of the highest quality submit any errata to publishases veya Copyright 2019. Ivey Business School Foundation Version 2019-12-11 In mid-October 2014, YJ Yang, Asia Pacific Lean Six Sigma director at Carestream Health Inc. (CHX) in Xiamen, was surprised when his colleague and long-time friend Yi Zheng, logistics manager, declared, "We are in trouble now!" Zheng had just received an email from Carestream Health Inc.'s (Carestream) U.S. subsidiary indicating that wide rolls of film, a key material needed for CHX production, would not arrive on time due to a labour dispute in the U.S. West Coast ports. Such a delay would lead to a shortage of raw materials, which would turn into a backlog of CHX deliveries to its customers. "We must look for some countermeasures immediately," said Zheng. Yang knew about the labour dispute and its disruptive impact to transportation out of the United States. He knew that this backlog would be a test for CHX's lean supply chain, something that he had never encountered before. CARESTREAM HEALTH INC. (CARE STREAM) Carestream was a medical devices manufacturer that was founded in 2007 by Onex Inc. after the acquisition of Eastman Kodak's Medical Imaging Group. With about 50 per cent market share, Carestream became the world leader in X-ray film production, a significant segment of the medical devices industry. CHX was a wholly-owned subsidiary of Carestream and mainly supplied the Asia-Pacific market, which was growing at a rate of 10 per cent per year. CHX's revenues were expected to exceed 2 billion in 2014 (see Exhibit 1). CHX had been vigorously implementing lean production since 2007. Yang, who was the head of Kodak's icrosoft Edge -- the fast. new browser built for Windows 10 Change my defaul Don't as Over the years, Yang and his team had accumulated a rich experience in lean production and established a lean production system for CHX.To achieve the operational objectives of zero accident safety, zero-defect quality, lowest cost, 100 per cent on-time delivery, and 100 per cent staff participation, CHX conducted on-time and automated production through standardized operations, on-site improvement activities, six sigma activities, stabilized operations, and leveled operations. As a result of these lean management efforts, CHX operations received numerous accolades in 2013 including a membership in the top 10 industrial enterprises in Xiamen and the top 300 industrial enterprises in the province of Fujian. CARESTREAM HEALTH INC. (XIAMEN) (CHX) SUPPLY CHAIN Wide rolls of film were supplied by Carestream's U.S. facilities located in Rochester, New York: Windsor, Colorado, and White City, Oregon, each using a high quality patented film coating. CHX was a large buyer of the film produced in Carestream's U.S. facilities---CHX's wide roll needs accounted for about 80 per cent of Carestream's U.S. production. Different sizes of wide rolls were shipped to Xiamen to be cut and finished into different dimensions of films ready for use in hospitals and clinics (see Exhibit 2). The finished goods were sold to the agents and end-user hospitals and clinics through an internal trade company Carestream Health Asia Pacific (see Exhibit 3). Due to the continuous improvements and creative solutions from lean management, CHX maintained the inventory of wide rolls at a low level; its "days in supply inventory" (DSI) was less than 30 days-that was the time spent by a wide roll in the entire supply chain. In other words, a wide roll leaving the U.S. supplier took 50 days to be received at CHX, processed, delivered, and paid for by customers To be specific, a wide roll leaving the Windsor, Colorado, facility took eight days of ground transportation (a mix of trucking and rail) to get to one of the West Coast ports. The maritime transportation portion of the supply chain (including the port's operations) was estimated at 17 days with an additional four days to clear all of the custom requirements in Xiamen. Overall the time between Windsor, Colorado, and the CHX plant was estimated to be a minimum 22 day's with an additional variation of seven days on average. Because of this variability, about two days' worth of supplies were kept as a buffer at CHX To turn a wide roll into a packaged finished product, including the time in inventory generally took about 10 days. The time to distribute the product and to receive the payment from the customers accounted for another 10 days In recent years, CHX had extended its lean management expertise to its supply chain. Both raw material and product inventories were maintained at a low level. The movement of goods was stabilized through connecting flows, meaning that the orders to the U.S. facilities were leveled and coordinated with the CHX leveled production. Multiple visual cues related to the upstream flows were updated daily and allowed management to pinpoint problems quickly. In reality, CHX worked to smooth (or level) the production at its plant and established a pace with relatively constant order size, which helped the upstream US facilities to avoid peaks and valleys in the wide rolls demand As Zheas put it "Over recent years, we have established the leveling mechanism which is key for stabilization. The material flow has been pulled by uning & Kanbanwystem, and the upstream and downstream fluctuations have been absorbed by a certain level of inventory--the buffer. Unfortunately, such a system was greatly affected by the labour dispute in the US West Coast porta Edge - the fast, new browser built for Windows 10 Change my defaul . Analyze the company using the information from the case study and also from online sources. . Review the company's business and competitors. Were other companies affected by the strike? 3. Was the company affected by the dock strikes last year? Has the company been affected by Covid-19? What happened? 4. What causes variation in the company's supply chain? 5. What were the managerial problems caused by the labor strike? What are the company's options? What is the feasibility of those options? Provide your reasoning. 6. If you were a manager in the meeting how would you decide when to use airfreight and how would you calculate the relative cost of airfreight vs. regular transport? LABOUR DISPUTE IN THE U.S. WEST COAST PORTS The labour dispute with the dock workers in October 2014 affected the ports on the U.S. West Coast, including Long Beach, Los Angeles, Seattle, Oakland, and 29 others. Those ports were handling half the U.S. business exporting and importing by sea, which represented more than 70 per cent of goods imported from Asia. The labour dispute took a turn for the worse when the workers decided to reduce the pace of their workthe slowdown was significant. Handling was reduced from 25 to 35 containers per hour to 10 to 18 containers. During the slowdown, major shippers such as Maersk, MSC, and China Shipping Group were facing increasing problems to ship out merchandise. Yang, in an encouraging tone, told Zheng It appears that we are in trouble, but don't be afraid [of] the crisis, perhaps it is a moment of peculiar proof that our lean supply chain actually works. Please collect some key data and call a meeting with the appropriate managers. Let's meet in the war room in 20 minutes. Please do not forget to invite Zhang, the general manager to join; he must be informed and provide his support to us. CRISIS MANAGEMENT MEETING The meeting started at 9:30, with managers from all the departments ready to address the issue. Zheng briefed her colleagues about the seriousness of the situation--the attendees were rather shocked. Zheng shared with everyone the recent inventory data: the wide roll inventory at CHX had dropped to a range of 2 to 6 days, down from a range of 8 to 12 earlier in the month (see Exhibit 4). The risk of material shortage was going to happen at any time. Shipping lead-time between the U.S. ports and Xiamen had significant fluctuations, and the stable supply of wide rolls developed in recent years appeared to be uncertain (see Exhibit 5). In addition to the challenge brought on by the labour dispute in the United States, the timing was not ideal as it was coinciding with higher demand from external downstream supply chain entities such as the agents and the end users. Over the past years, Cold Spring Harbour (CSH) Asia (the distribution arm of Carestream in East Asia) experienced higher than normal demand for X-rays as agents tried to achieve their yearly goals. Agents and hospitals also wanted to build inventory before the Spring Festival holidays. If Carestream ran out of film supply, competitors like Fuji and Agfa would have an opportunity to increase their market share-a highly undesirable scenario for Carestream As the shortage of raw materials had the most impact on production, WL Zhao, the production manager commented We thought lean production was the right way for us in the past, however, I have a little bit [of] concem now. Is it the appropriate way to maintain such a low inventory, which has led the supply chain to be very weak in response to the external crisis? Do we shoot ourselves in the foot? Besides, the capacity of our production line has reached (a) maximum of 90 per cent; there's not much more potential for further development. What shall we do now? NT Lus, the quality manager proposed "Can we transport the wide rolls by air? As far as I have known, we could get the wide roll in no more than one week by aurreight Anoressare 'Economy Reng - Ver Coasters and Recor Fay 22 508 PA Zhang, the general manager, asked, "How much will the cost increase if wide rolls [are) transported by air?" "The recent freight has fluctuated severely, and the cost for airfreight may be about 9 to 10 times more costly than delivering by sea," Zheng replied. She added the following aspects to consider in the discussion: Once handed over to the port, the containers became unavailable to ship by airfreight but were going to be shipped eventually. Starting airfreighting can create some sort of chaos in the supply of CHX. It could be perceived "as digging the soil behind you to fill the pit in front of you." How [can we] fill the new pit [that] appeared? It is a vicious circie. The production capacity of the U.S. supplier also had its limit; therefore, the choice was not only between airfreight and shipping by sea; assessing accurate market demand and production needs was essential when planning orders for wide rolls, but the recurrent higher demand at the end of the year was difficult to assess As well, airfreight came with higher transportation costs, and other costs needed to be considered including changes to the plan and program cuts that came with the use of expedited delivery by air-increases in cutting scrap rate, decreases of equipment activation excess of labour, and other management issues. After some discussion of possible alternatives (e.g., shipping through Mexico or Canada, using East Coast ports), Zhang reacted by stating: It seems that the straw cannot be clutched at without any concerns. We must face these problems sooner or later, and some sacrifices are inevitable. The ultimate goal is to keep the market not out of stock; otherwise, the market share will be handed over to competitors easily. Now we should get ourselves out of confusion and figure out an optimal solution. When the attention turned to him for a proposed optimal solution, Yang said he needed time to sort out his ideas and to look at the different perspectives. Although the decision to use airfreight was made while discounting other alternatives. Yang needed to figure out the key aspects of an airfreight solution: When should CHX use airfreight for its supply of wide rolls? How many rolls should be airfreighted each time! In other words, what should be the mechanism to govern the use of airfreight TREAM HEALTH INC. (XIAMENTOPERATIONAL INDICATORS 2012-2014 Year Number of Employees 2012 Output (RMB millions) (Million square meters) 1,870 29 2,200 36 2,180 42 2013 2014 230 220 200 Note: 2014 figures are estimated for the year as of October Source: Created by the case authors from company files EXHIBIT 2: PRODUCTION FLOW AT CARESTREAM HEALTH INC. (XIAMEN) Darkroom operating area Photosensitive wide rolls longitudinal cutting Cut wide rolls storage Imported photosensitive wide rolls Cutting wide roll horizontal with of without additional longitudinal cutting Sub-volume of cut wide rolls Processing of bulk film Internal package of bulk film Intemal package of rolled film Packaging materials External package processing External package of film product Finished product warehousing A Read aloud DIRE EXHIBIT 3: SUPPLY CHAIN DIAGRAM OF CARE STREAM HEALTH INC. Carestream US Wide rolls CHX Finished goods Carestream Asia Pacific Agents Rochester, New York Windsor Colorado White City, Oregon End users Source Created by the case authors from company files EXHIBIT 4: CARE STREAM HEALTH INC. (XIAMEN) WIDE ROLL INVENTORY CHIX wide roll inventory (SI) 14 } mantha Source: Created by the case authors from companyies EXHIBIT 5: WIDE ROLLS LEAD-TIME (WEST COAST PORTS TO XIAMEN) mm Source: Cebyre te mostra ktop/document(6).pdf Fit to width Page view CARESTREAM HEALTH INC.: WHEN DISRUPTION HITS A LEAN SUPPLY CHAIN Stephan Vachon Zhiduan Xu, and De Gao wrote this case solely to provide material for class discussion. The authors do not intend to slustrate the effective or ineffective handling of a managerial situation. The authors may have disguised certain names and other identifying information to protect confidentiality This publication may not be transmitted, photocopied, digitized or otherwise reproduced in any form or by any means without the permission of the copyright holder. Reproduction of this material is not covered under authorization by any reproduction rights organization. To order copies or request permission to reproduce materials contact Ivey Publishing. Ivey Business School Western University, London, Ontario, Canada, NOG ONT (9 519 661 3208(e) cases@veyca www.iveycases.com Our goal is to publish materials of the highest quality submit any errata to publishases veya Copyright 2019. Ivey Business School Foundation Version 2019-12-11 In mid-October 2014, YJ Yang, Asia Pacific Lean Six Sigma director at Carestream Health Inc. (CHX) in Xiamen, was surprised when his colleague and long-time friend Yi Zheng, logistics manager, declared, "We are in trouble now!" Zheng had just received an email from Carestream Health Inc.'s (Carestream) U.S. subsidiary indicating that wide rolls of film, a key material needed for CHX production, would not arrive on time due to a labour dispute in the U.S. West Coast ports. Such a delay would lead to a shortage of raw materials, which would turn into a backlog of CHX deliveries to its customers. "We must look for some countermeasures immediately," said Zheng. Yang knew about the labour dispute and its disruptive impact to transportation out of the United States. He knew that this backlog would be a test for CHX's lean supply chain, something that he had never encountered before. CARESTREAM HEALTH INC. (CARE STREAM) Carestream was a medical devices manufacturer that was founded in 2007 by Onex Inc. after the acquisition of Eastman Kodak's Medical Imaging Group. With about 50 per cent market share, Carestream became the world leader in X-ray film production, a significant segment of the medical devices industry. CHX was a wholly-owned subsidiary of Carestream and mainly supplied the Asia-Pacific market, which was growing at a rate of 10 per cent per year. CHX's revenues were expected to exceed 2 billion in 2014 (see Exhibit 1). CHX had been vigorously implementing lean production since 2007. Yang, who was the head of Kodak's icrosoft Edge -- the fast. new browser built for Windows 10 Change my defaul Don't as Over the years, Yang and his team had accumulated a rich experience in lean production and established a lean production system for CHX.To achieve the operational objectives of zero accident safety, zero-defect quality, lowest cost, 100 per cent on-time delivery, and 100 per cent staff participation, CHX conducted on-time and automated production through standardized operations, on-site improvement activities, six sigma activities, stabilized operations, and leveled operations. As a result of these lean management efforts, CHX operations received numerous accolades in 2013 including a membership in the top 10 industrial enterprises in Xiamen and the top 300 industrial enterprises in the province of Fujian. CARESTREAM HEALTH INC. (XIAMEN) (CHX) SUPPLY CHAIN Wide rolls of film were supplied by Carestream's U.S. facilities located in Rochester, New York: Windsor, Colorado, and White City, Oregon, each using a high quality patented film coating. CHX was a large buyer of the film produced in Carestream's U.S. facilities---CHX's wide roll needs accounted for about 80 per cent of Carestream's U.S. production. Different sizes of wide rolls were shipped to Xiamen to be cut and finished into different dimensions of films ready for use in hospitals and clinics (see Exhibit 2). The finished goods were sold to the agents and end-user hospitals and clinics through an internal trade company Carestream Health Asia Pacific (see Exhibit 3). Due to the continuous improvements and creative solutions from lean management, CHX maintained the inventory of wide rolls at a low level; its "days in supply inventory" (DSI) was less than 30 days-that was the time spent by a wide roll in the entire supply chain. In other words, a wide roll leaving the U.S. supplier took 50 days to be received at CHX, processed, delivered, and paid for by customers To be specific, a wide roll leaving the Windsor, Colorado, facility took eight days of ground transportation (a mix of trucking and rail) to get to one of the West Coast ports. The maritime transportation portion of the supply chain (including the port's operations) was estimated at 17 days with an additional four days to clear all of the custom requirements in Xiamen. Overall the time between Windsor, Colorado, and the CHX plant was estimated to be a minimum 22 day's with an additional variation of seven days on average. Because of this variability, about two days' worth of supplies were kept as a buffer at CHX To turn a wide roll into a packaged finished product, including the time in inventory generally took about 10 days. The time to distribute the product and to receive the payment from the customers accounted for another 10 days In recent years, CHX had extended its lean management expertise to its supply chain. Both raw material and product inventories were maintained at a low level. The movement of goods was stabilized through connecting flows, meaning that the orders to the U.S. facilities were leveled and coordinated with the CHX leveled production. Multiple visual cues related to the upstream flows were updated daily and allowed management to pinpoint problems quickly. In reality, CHX worked to smooth (or level) the production at its plant and established a pace with relatively constant order size, which helped the upstream US facilities to avoid peaks and valleys in the wide rolls demand As Zheas put it "Over recent years, we have established the leveling mechanism which is key for stabilization. The material flow has been pulled by uning & Kanbanwystem, and the upstream and downstream fluctuations have been absorbed by a certain level of inventory--the buffer. Unfortunately, such a system was greatly affected by the labour dispute in the US West Coast porta Edge - the fast, new browser built for Windows 10 Change my defaul . Analyze the company using the information from the case study and also from online sources. . Review the company's business and competitors. Were other companies affected by the strike? 3. Was the company affected by the dock strikes last year? Has the company been affected by Covid-19? What happened? 4. What causes variation in the company's supply chain? 5. What were the managerial problems caused by the labor strike? What are the company's options? What is the feasibility of those options? Provide your reasoning. 6. If you were a manager in the meeting how would you decide when to use airfreight and how would you calculate the relative cost of airfreight vs. regular transport? LABOUR DISPUTE IN THE U.S. WEST COAST PORTS The labour dispute with the dock workers in October 2014 affected the ports on the U.S. West Coast, including Long Beach, Los Angeles, Seattle, Oakland, and 29 others. Those ports were handling half the U.S. business exporting and importing by sea, which represented more than 70 per cent of goods imported from Asia. The labour dispute took a turn for the worse when the workers decided to reduce the pace of their workthe slowdown was significant. Handling was reduced from 25 to 35 containers per hour to 10 to 18 containers. During the slowdown, major shippers such as Maersk, MSC, and China Shipping Group were facing increasing problems to ship out merchandise. Yang, in an encouraging tone, told Zheng It appears that we are in trouble, but don't be afraid [of] the crisis, perhaps it is a moment of peculiar proof that our lean supply chain actually works. Please collect some key data and call a meeting with the appropriate managers. Let's meet in the war room in 20 minutes. Please do not forget to invite Zhang, the general manager to join; he must be informed and provide his support to us. CRISIS MANAGEMENT MEETING The meeting started at 9:30, with managers from all the departments ready to address the issue. Zheng briefed her colleagues about the seriousness of the situation--the attendees were rather shocked. Zheng shared with everyone the recent inventory data: the wide roll inventory at CHX had dropped to a range of 2 to 6 days, down from a range of 8 to 12 earlier in the month (see Exhibit 4). The risk of material shortage was going to happen at any time. Shipping lead-time between the U.S. ports and Xiamen had significant fluctuations, and the stable supply of wide rolls developed in recent years appeared to be uncertain (see Exhibit 5). In addition to the challenge brought on by the labour dispute in the United States, the timing was not ideal as it was coinciding with higher demand from external downstream supply chain entities such as the agents and the end users. Over the past years, Cold Spring Harbour (CSH) Asia (the distribution arm of Carestream in East Asia) experienced higher than normal demand for X-rays as agents tried to achieve their yearly goals. Agents and hospitals also wanted to build inventory before the Spring Festival holidays. If Carestream ran out of film supply, competitors like Fuji and Agfa would have an opportunity to increase their market share-a highly undesirable scenario for Carestream As the shortage of raw materials had the most impact on production, WL Zhao, the production manager commented We thought lean production was the right way for us in the past, however, I have a little bit [of] concem now. Is it the appropriate way to maintain such a low inventory, which has led the supply chain to be very weak in response to the external crisis? Do we shoot ourselves in the foot? Besides, the capacity of our production line has reached (a) maximum of 90 per cent; there's not much more potential for further development. What shall we do now? NT Lus, the quality manager proposed "Can we transport the wide rolls by air? As far as I have known, we could get the wide roll in no more than one week by aurreight Anoressare 'Economy Reng - Ver Coasters and Recor Fay 22 508 PA Zhang, the general manager, asked, "How much will the cost increase if wide rolls [are) transported by air?" "The recent freight has fluctuated severely, and the cost for airfreight may be about 9 to 10 times more costly than delivering by sea," Zheng replied. She added the following aspects to consider in the discussion: Once handed over to the port, the containers became unavailable to ship by airfreight but were going to be shipped eventually. Starting airfreighting can create some sort of chaos in the supply of CHX. It could be perceived "as digging the soil behind you to fill the pit in front of you." How [can we] fill the new pit [that] appeared? It is a vicious circie. The production capacity of the U.S. supplier also had its limit; therefore, the choice was not only between airfreight and shipping by sea; assessing accurate market demand and production needs was essential when planning orders for wide rolls, but the recurrent higher demand at the end of the year was difficult to assess As well, airfreight came with higher transportation costs, and other costs needed to be considered including changes to the plan and program cuts that came with the use of expedited delivery by air-increases in cutting scrap rate, decreases of equipment activation excess of labour, and other management issues. After some discussion of possible alternatives (e.g., shipping through Mexico or Canada, using East Coast ports), Zhang reacted by stating: It seems that the straw cannot be clutched at without any concerns. We must face these problems sooner or later, and some sacrifices are inevitable. The ultimate goal is to keep the market not out of stock; otherwise, the market share will be handed over to competitors easily. Now we should get ourselves out of confusion and figure out an optimal solution. When the attention turned to him for a proposed optimal solution, Yang said he needed time to sort out his ideas and to look at the different perspectives. Although the decision to use airfreight was made while discounting other alternatives. Yang needed to figure out the key aspects of an airfreight solution: When should CHX use airfreight for its supply of wide rolls? How many rolls should be airfreighted each time! In other words, what should be the mechanism to govern the use of airfreight TREAM HEALTH INC. (XIAMENTOPERATIONAL INDICATORS 2012-2014 Year Number of Employees 2012 Output (RMB millions) (Million square meters) 1,870 29 2,200 36 2,180 42 2013 2014 230 220 200 Note: 2014 figures are estimated for the year as of October Source: Created by the case authors from company files EXHIBIT 2: PRODUCTION FLOW AT CARESTREAM HEALTH INC. (XIAMEN) Darkroom operating area Photosensitive wide rolls longitudinal cutting Cut wide rolls storage Imported photosensitive wide rolls Cutting wide roll horizontal with of without additional longitudinal cutting Sub-volume of cut wide rolls Processing of bulk film Internal package of bulk film Intemal package of rolled film Packaging materials External package processing External package of film product Finished product warehousing A Read aloud DIRE EXHIBIT 3: SUPPLY CHAIN DIAGRAM OF CARE STREAM HEALTH INC. Carestream US Wide rolls CHX Finished goods Carestream Asia Pacific Agents Rochester, New York Windsor Colorado White City, Oregon End users Source Created by the case authors from company files EXHIBIT 4: CARE STREAM HEALTH INC. (XIAMEN) WIDE ROLL INVENTORY CHIX wide roll inventory (SI) 14 } mantha Source: Created by the case authors from companyies EXHIBIT 5: WIDE ROLLS LEAD-TIME (WEST COAST PORTS TO XIAMEN) mm Source: Cebyre te mostra