Question: Let's assume that a process layout is used for manufacturing this product. After each component of the product (1, 2, 3, and 4) goes through

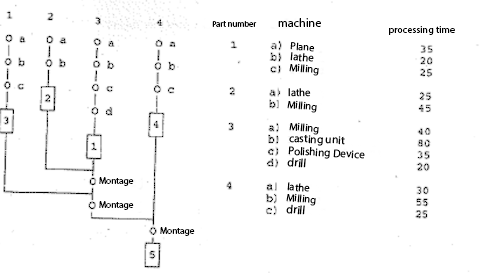

Let's assume that a process layout is used for manufacturing this product. After each component of the product (1, 2, 3, and 4) goes through the respective machines shown in the above diagram, they are sent to the assembly and painting workshop and finally stacked in the warehouse. Therefore, a facility design will be made for the factory consisting of 7 departments: Mechanical Processing Workshop (including planer, lathe, and milling machines), Casting Workshop, Drilling Workshop, Polishing Workshop, Assembly Workshop, Painting Workshop, and Warehouse. The space requirements for the departments other than the Assembly Workshop, Painting Workshop, and Warehouse will be calculated considering the number of machines required in those departments. The required space for each machine is as follows: planer (2 square meters), lathe (5 square meters), milling machine (5 square meters), polishing machine (2 square meters), drill (1 square meter), and casting unit (10 square meters). It is known that when calculating these areas, an additional area equal to 20% of the space required for the operator's work is also needed. The Assembly Workshop requires 300 square meters, the Painting Workshop requires 100 square meters, and the warehouse requires 1000 square meters of space.

While the produced 1st, 2nd, and 4th components correspond to one unit load, the volume of the produced 3rd component is 500 cm. It is known that this component is quite heavy, has a square base, can be drawn, is clean, and is of medium value. Therefore, it is necessary to calculate how many unit loads this component represents. Afterwards, create the travel schedule for this production.

Part number machine processing time 1.a)Planeb)lathec)Milling2a)latheb)Milling34c)drill35202525452)Millingb)castingunitc)PolishingDeviced)drilla)latheb)Milling25408035203055

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts