Question: Linear Programming: Lesson in Excel (using solver) or Lindo Transshipment Model: This is an extension of the transportation model. There are now intermediate transshipment points

Linear Programming:

Lesson in Excel (using solver) or Lindo

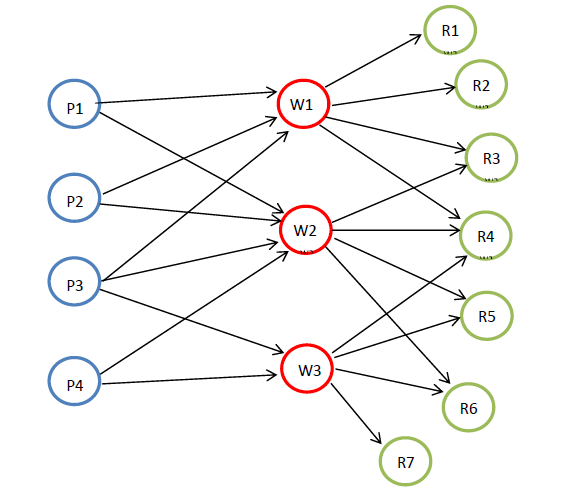

Transshipment Model: This is an extension of the transportation model. There are now intermediate transshipment points added between the sources (plants) and destinations (retailers). Items being shipped from a Plant (pi) must be shipped to a Warehouse (wj) before being shipped to the Retailer (rk). Each Plant will have an associated supply (si) and each Retailer will have a demand (dk). The number of plants is n, number of warehouses is q and the number of retailers is m. The edges (i,j) from plant (pi)to warehouse (wj) have costs associated denoted cp(i,j). The edges (j,k) from a warehouse (wj)to a retailer (rk) have costs associated denoted cw(j,k). The graph below shows the transshipment map for a manufacturer of refrigerators. Refrigerators are produced at four plants and then shipped to a warehouse (weekly) before going to the retailer.

Below are the costs of shipping from a plant to a warehouse and then a warehouse to a retailer. If it is impossible to ship between the two locations an X is placed in the table.

| cost | W1 | W2 | W3 |

| P1 | $10 | $15 | X |

| P2 | $11 | $8 | X |

| P3 | $13 | $8 | $9 |

| P4 | X | $14 | 8 |

| cost | R1 | R2 | R3 | R4 | R5 | R6 | R7 |

| W1 | $5 | $6 | $7 | $10 | X | X | X |

| W2 | X | X | $12 | $8 | $10 | $14 | X |

| W3 | X | X | X | $14 | $12 | $12 | $6 |

| P1 | P2 | P3 | P4 | |

| Supply | 150 | 450 | 250 | 150 |

| R1 | R2 | R3 | R4 | R5 | R6 | R7 | |

| Demand | 100 | 150 | 100 | 200 | 200 | 150 | 100 |

Lesson in Excel (using Solver) or Lindo

Part 1: The optimal shipping routes and minimum cost is $17100 but due to old infrastructure Warehouse 2 is going to close eliminating all of the associated routes. What is the optimal solution for this modified model? Is it feasible to ship all the refrigerators to either warehouse 1 or 3 and then to the retailers without using warehouse 2? Why or why not?

Part 2: Instead of closing Warehouse 2 management has decide to keep a portion of it open but limit shipments to 100 refrigerators per week. Is this feasible? If so what is the optimal solution when warehouse 2 is limited to 100 refrigerators?

R1 R2 P1 W1 P2 P3 R5 R6 R7 R1 R2 P1 W1 P2 P3 R5 R6 R7

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts