Question: Linear Programming: Lesson in Excel (using solver) or Lindo Transshipment Model: This is an extension of the transportation model. There are now intermediate transshipment points

Linear Programming:

Lesson in Excel (using solver) or Lindo

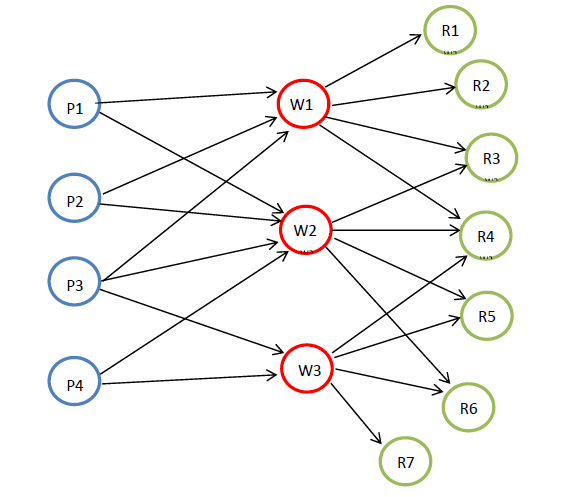

Transshipment Model: This is an extension of the transportation model. There are now intermediate transshipment points added between the sources (plants) and destinations (retailers). Items being shipped from a Plant (pi) must be shipped to a Warehouse (wj) before being shipped to the Retailer (rk). Each Plant will have an associated supply (si) and each Retailer will have a demand (dk). The number of plants is n, number of warehouses is q and the number of retailers is m. The edges (i,j) from plant (pi)to warehouse (wj) have costs associated denoted cp(i,j). The edges (j,k) from a warehouse (wj)to a retailer (rk) have costs associated denoted cw(j,k). The graph below shows the transshipment map for a manufacturer of refrigerators. Refrigerators are produced at four plants and then shipped to a warehouse (weekly) before going to the retailer.

Below are the costs of shipping from a plant to a warehouse and then a warehouse to a retailer. If it is impossible to ship between the two locations an X is placed in the table.

| cost | W1 | W2 | W3 |

| P1 | $10 | $15 | X |

| P2 | $11 | $8 | X |

| P3 | $13 | $8 | $9 |

| P4 | X | $14 | 8 |

| cost | R1 | R2 | R3 | R4 | R5 | R6 | R7 |

| W1 | $5 | $6 | $7 | $10 | X | X | X |

| W2 | X | X | $12 | $8 | $10 | $14 | X |

| W3 | X | X | X | $14 | $12 | $12 | $6 |

| P1 | P2 | P3 | P4 | |

| Supply | 150 | 450 | 250 | 150 |

| R1 | R2 | R3 | R4 | R5 | R6 | R7 | |

| Demand | 100 | 150 | 100 | 200 | 200 | 150 | 100 |

Lesson in Excel (using Solver) or Lindo

Part 1: Determine the number of refrigerators to be shipped from the plants to the warehouses and then warehouses to retailers to minimize the cost. Formulate the problem as a linear program with an objective function and all constraints. Determine the optimal solution for the linear program using any software you want. What are the optimal shipping routes and minimum cost?

Part 2: Due to old infrastructure Warehouse 2 is going to close eliminating all of the associated routes. What is the optimal solution for this modified model? Is it feasible to ship all the refrigerators to either warehouse 1 or 3 and then to the retailers without using warehouse 2? Why or why not?

Part 3: Instead of closing Warehouse 2 management has decide to keep a portion of it open but limit shipments to 100 refrigerators per week. Is this feasible? If so what is the optimal solution when warehouse 2 is limited to 100 refrigerators?

R1 R2 P1 W1 P2 P3 R5 R6 R7

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts