Question: Management Decision Science a) What is the economic order quantity (EOQ)? b) Calculate the annual inventory cost. c) Determine the number of orders that will

Management Decision Science

a) What is the economic order quantity (EOQ)? b) Calculate the annual inventory cost. c) Determine the number of orders that will be made in a year. d) What is the Reorder Point (ROP)? e) Currently, the companys inventory policy is to order 500 units per month and the lead time would reduce 10 days for this large quantity. If Southeastern Division using the current policy, what is the new ROP? f) What is the annual inventory cost if the division purchased using the current policy? Should they order using the current policy or EOQ?

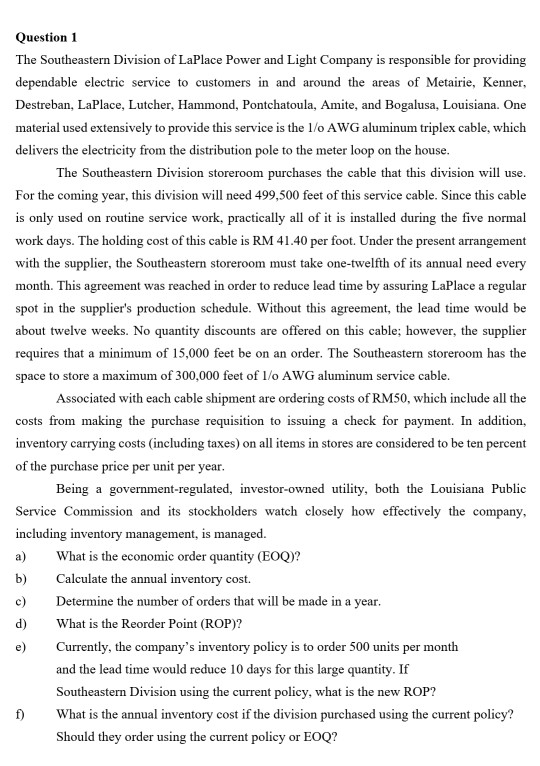

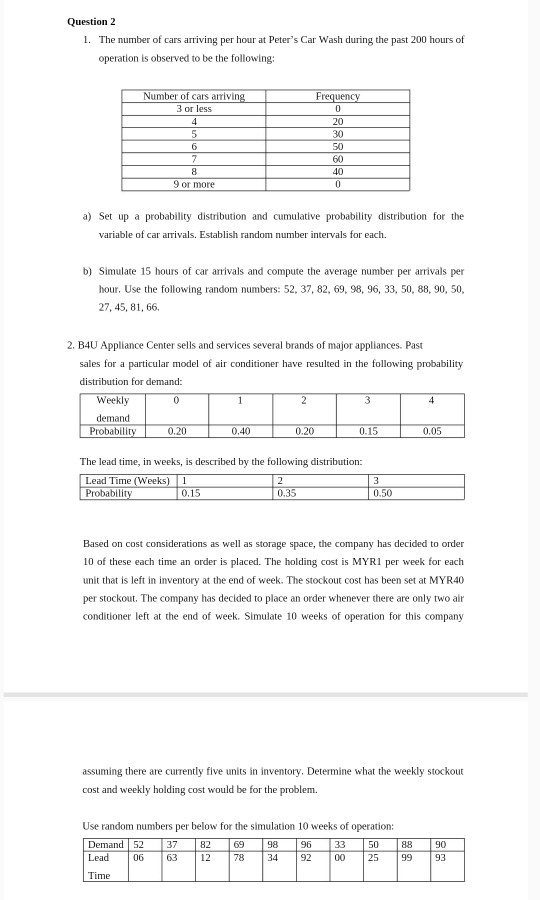

Question 1 The Southeastern Division of LaPlace Power and Light Company is responsible for providing dependable electric service to customers in and around the areas of Metairie, Kenner, Destreban, LaPlace, Lutcher, Hammond, Pontchatoula, Amite, and Bogalusa, Louisiana. One material used extensively to provide this service is the 1/0 AWG aluminum triplex cable, which delivers the electricity from the distribution pole to the meter loop on the house. The Southeastern Division storeroom purchases the cable that this division will use. For the coming year, this division will need 499,500 feet of this service cable. Since this cable is only used on routine service work, practically all of it is installed during the five normal work days. The holding cost of this cable is RM 41.40 per foot. Under the present arrangement with the supplier, the Southeastern storeroom must take one-twelfth of its annual need every month. This agreement was reached in order to reduce lead time by assuring LaPlace a regular spot in the supplier's production schedule. Without this agreement, the lead time would be about twelve weeks. No quantity discounts are offered on this cable; however, the supplier requires that a minimum of 15,000 feet be on an order. The Southeastern storeroom has the space to store a maximum of 300,000 feet of 1/0 AWG aluminum service cable. Associated with each cable shipment are ordering costs of RM50, which include all the costs from making the purchase requisition to issuing a check for payment. In addition, inventory carrying costs (including taxes) on all items in stores are considered to be ten percent of the purchase price per unit per year. Being a government-regulated, investor-owned utility, both the Louisiana Public Service Commission and its stockholders watch closely how effectively the company, including inventory management, is managed. a) What is the economic order quantity (EOQ)? b) Calculate the annual inventory cost. Determine the number of orders that will be made in a year, What is the Reorder Point (ROP)? Currently, the company's inventory policy is to order 500 units per month and the lead time would reduce 10 days for this large quantity. If Southeastern Division using the current policy, what is the new ROP? f) What is the annual inventory cost if the division purchased using the current policy? Should they order using the current policy or EOQ? Question 2 1. The number of cars arriving per hour at Peter's Car Wash during the past 200 hours of operation is observed to be the following: Number of cars arriving 3 or less 4 Frequency 0 20 30 60 9 or more a) Set up a probability distribution and cumulative probability distribution for the variable of car arrivals. Establish random number intervals for each. b) Simulate 15 hours of car arrivals and compute the average number per arrivals per hour. Use the following random numbers: 52, 37, 82, 69, 98, 96, 33, 50, 88, 90, 50, 27, 45, 81, 66. 2. B4U Appliance Center sells and services several brands of major appliances. Past sales for a particular model of air conditioner have resulted in the following probability distribution for demand: Weekly 0 3 4 demand Probability 0.20 0.40 0.20 0.15 0.05 The lead time, in weeks, is described by the following distribution: Lead Time (Weeks) Probability 0.15 0.35 0.50 Based on cost considerations as well as storage space, the company has decided to order 10 of these each time an order is placed. The holding cost is MYRI per week for each unit that is left in inventory at the end of week. The stockout cost has been set at MYR 40 per stockout. The company has decided to place an order whenever there are only two alr conditioner left at the end of week. Simulate 10 weeks of operation for this company assuming there are currently five units in inventory. Determine what the weekly stockout cost and weekly holding cost would be for the problem. Use random numbers per below for the simulation 10 weeks of operation: Demand 52 37 82 69 98 96 33 50 88 90 Lead 06 63 12 78 34 92 0025 9993 Time Question 1 The Southeastern Division of LaPlace Power and Light Company is responsible for providing dependable electric service to customers in and around the areas of Metairie, Kenner, Destreban, LaPlace, Lutcher, Hammond, Pontchatoula, Amite, and Bogalusa, Louisiana. One material used extensively to provide this service is the 1/0 AWG aluminum triplex cable, which delivers the electricity from the distribution pole to the meter loop on the house. The Southeastern Division storeroom purchases the cable that this division will use. For the coming year, this division will need 499,500 feet of this service cable. Since this cable is only used on routine service work, practically all of it is installed during the five normal work days. The holding cost of this cable is RM 41.40 per foot. Under the present arrangement with the supplier, the Southeastern storeroom must take one-twelfth of its annual need every month. This agreement was reached in order to reduce lead time by assuring LaPlace a regular spot in the supplier's production schedule. Without this agreement, the lead time would be about twelve weeks. No quantity discounts are offered on this cable; however, the supplier requires that a minimum of 15,000 feet be on an order. The Southeastern storeroom has the space to store a maximum of 300,000 feet of 1/0 AWG aluminum service cable. Associated with each cable shipment are ordering costs of RM50, which include all the costs from making the purchase requisition to issuing a check for payment. In addition, inventory carrying costs (including taxes) on all items in stores are considered to be ten percent of the purchase price per unit per year. Being a government-regulated, investor-owned utility, both the Louisiana Public Service Commission and its stockholders watch closely how effectively the company, including inventory management, is managed. a) What is the economic order quantity (EOQ)? b) Calculate the annual inventory cost. Determine the number of orders that will be made in a year, What is the Reorder Point (ROP)? Currently, the company's inventory policy is to order 500 units per month and the lead time would reduce 10 days for this large quantity. If Southeastern Division using the current policy, what is the new ROP? f) What is the annual inventory cost if the division purchased using the current policy? Should they order using the current policy or EOQ? Question 2 1. The number of cars arriving per hour at Peter's Car Wash during the past 200 hours of operation is observed to be the following: Number of cars arriving 3 or less 4 Frequency 0 20 30 60 9 or more a) Set up a probability distribution and cumulative probability distribution for the variable of car arrivals. Establish random number intervals for each. b) Simulate 15 hours of car arrivals and compute the average number per arrivals per hour. Use the following random numbers: 52, 37, 82, 69, 98, 96, 33, 50, 88, 90, 50, 27, 45, 81, 66. 2. B4U Appliance Center sells and services several brands of major appliances. Past sales for a particular model of air conditioner have resulted in the following probability distribution for demand: Weekly 0 3 4 demand Probability 0.20 0.40 0.20 0.15 0.05 The lead time, in weeks, is described by the following distribution: Lead Time (Weeks) Probability 0.15 0.35 0.50 Based on cost considerations as well as storage space, the company has decided to order 10 of these each time an order is placed. The holding cost is MYRI per week for each unit that is left in inventory at the end of week. The stockout cost has been set at MYR 40 per stockout. The company has decided to place an order whenever there are only two alr conditioner left at the end of week. Simulate 10 weeks of operation for this company assuming there are currently five units in inventory. Determine what the weekly stockout cost and weekly holding cost would be for the problem. Use random numbers per below for the simulation 10 weeks of operation: Demand 52 37 82 69 98 96 33 50 88 90 Lead 06 63 12 78 34 92 0025 9993 TimeStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock