Question: Mary's Masks Inc. OPER2210 - MRP Case Study Hand-In - Winter 2021. Mary's Mask Inc. had started as a small business in the owner's house,

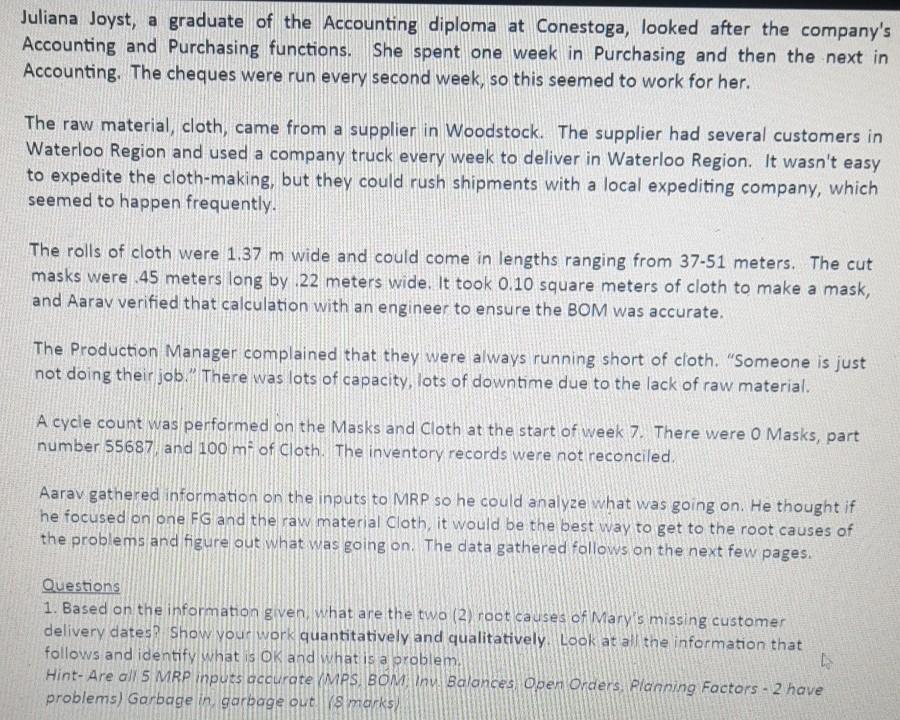

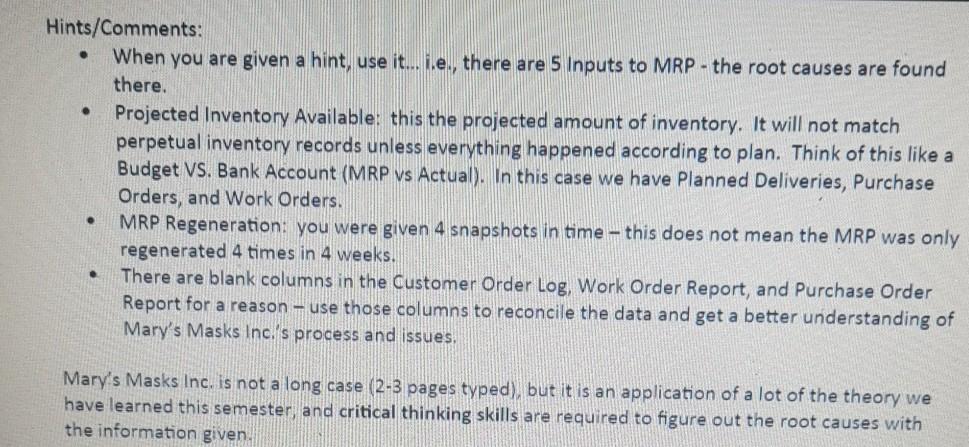

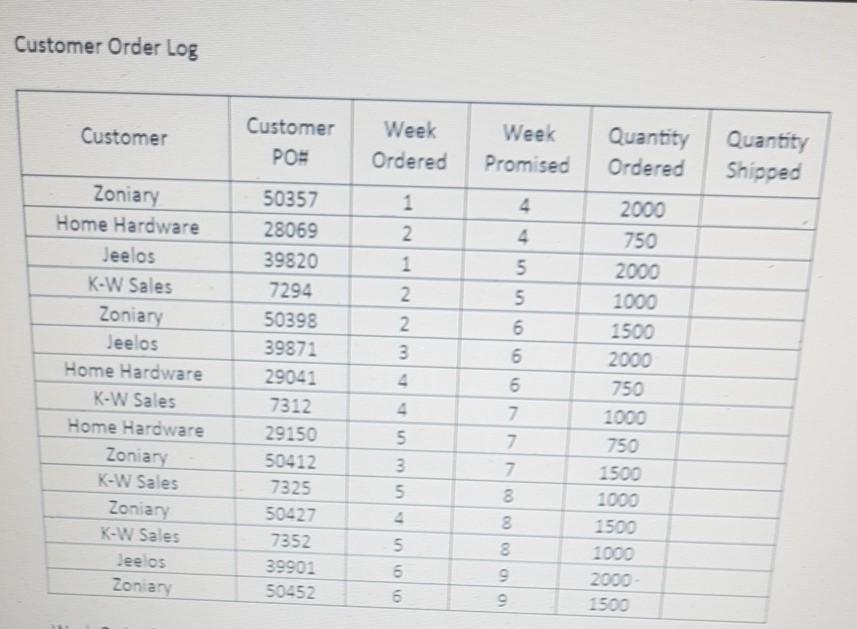

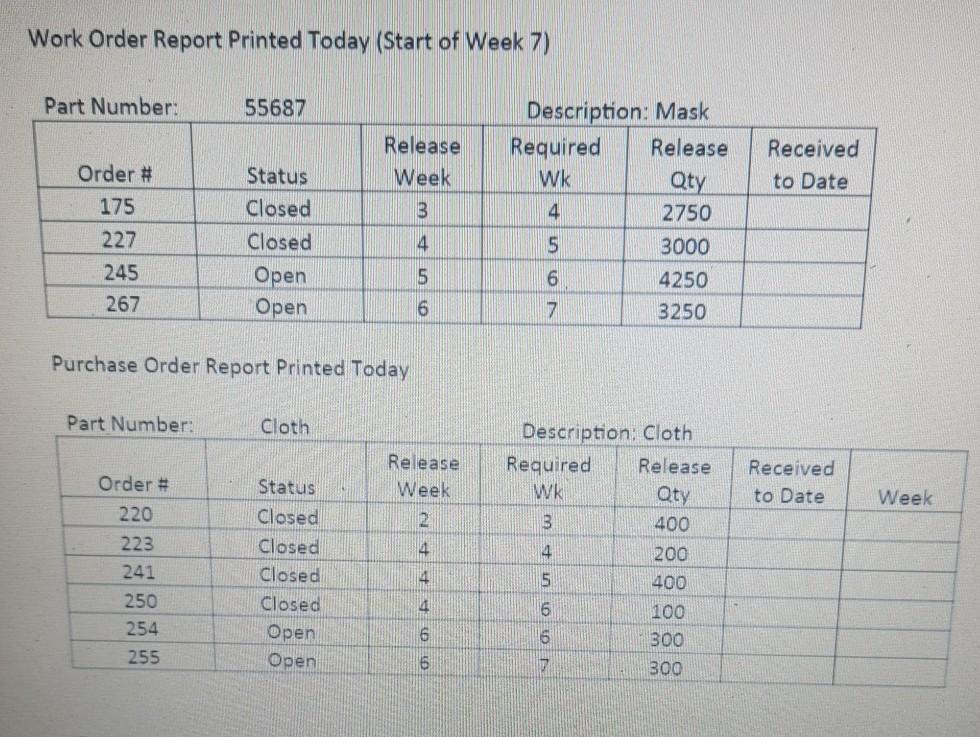

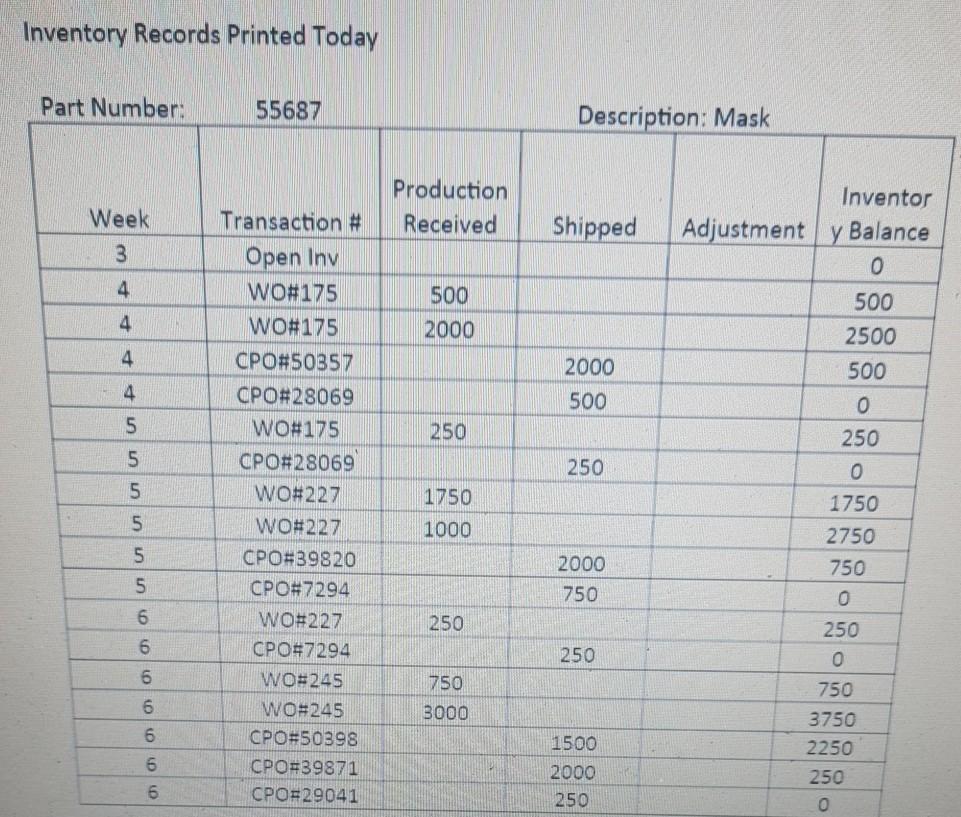

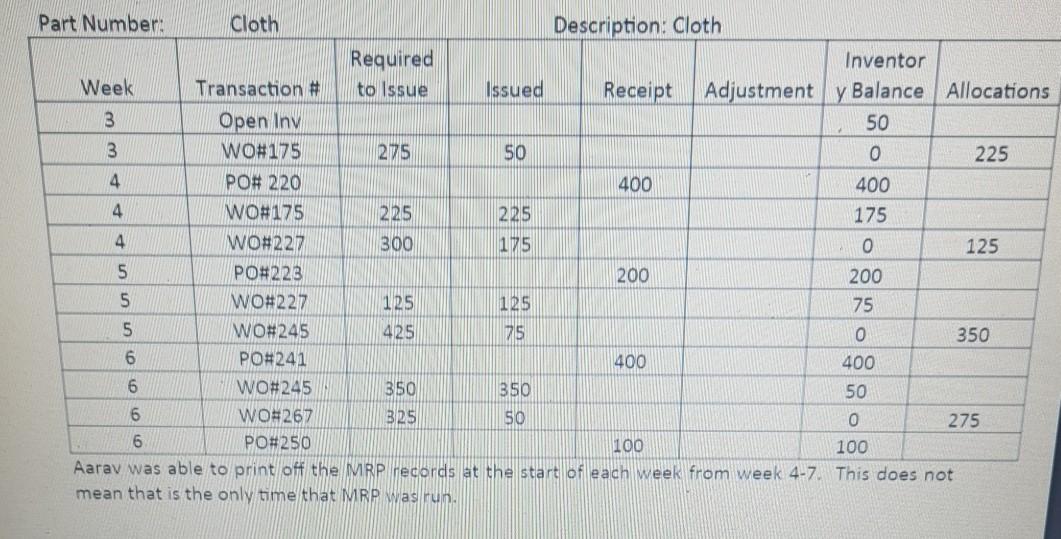

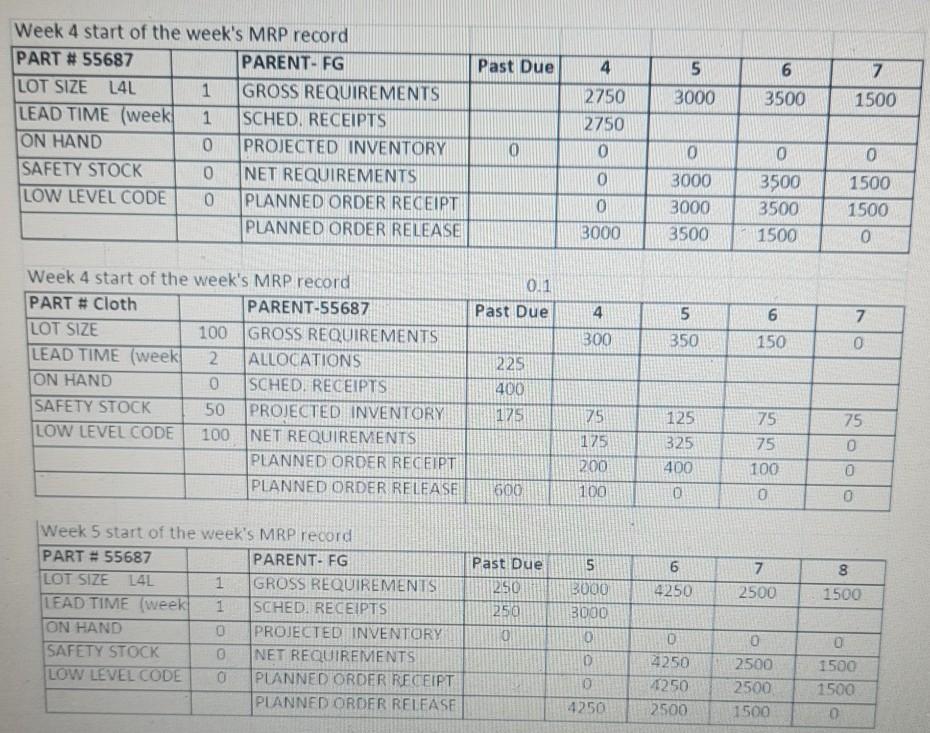

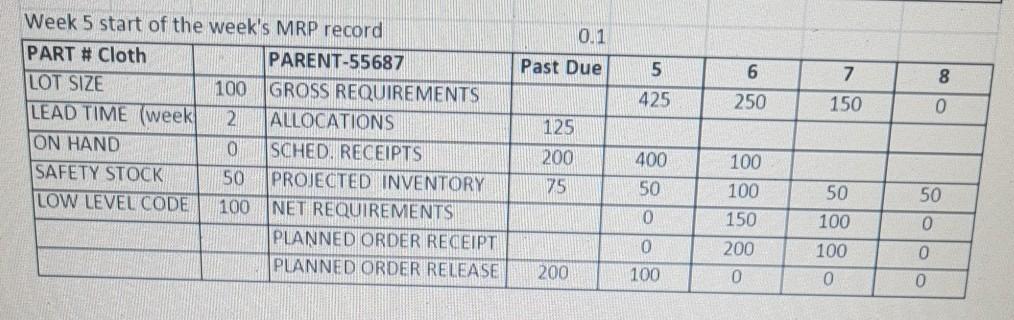

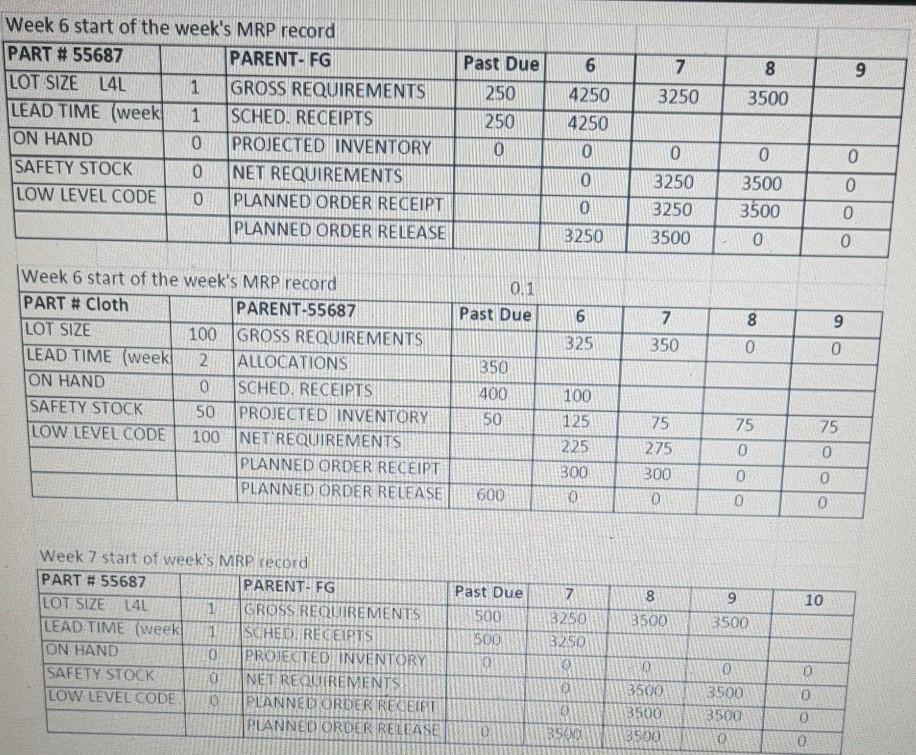

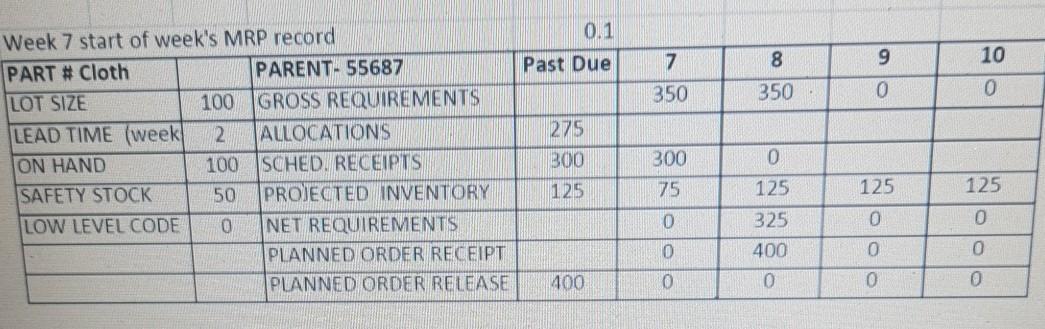

Mary's Masks Inc. OPER2210 - MRP Case Study Hand-In - Winter 2021. Mary's Mask Inc. had started as a small business in the owner's house, making pet coats and bandanas, Once the COVID pandemic started, Mary realized that she could pivot her business to making cloth masks that matched the pet items. Her business grew exponentially, which required her to move out of her house to a new larger location. The owner had previously taken some ASCM(APICS) review courses to understand good planning and control systems. She bought a small computerized software package to automate the material ordering processes. The modules they had implemented were Inventory, Purchasing, and MRP. Other modules were going to be implemented in the coming months. The implementation had gone well, and the software appeared to be working well. The customer base had been growing, and Costco had started to make some inquiries of Mary's Mask Inc. supplying them with cloth masks. The sky was the limit for sales, When Mary's Mask Inc. was small, the entrepreneur easily satisfied customer demand as she did everything herself. As the company grew larger meeting customer orders on a timely basis proved to be more difficult. In the last year, she hired several people who specialized in various parts of the business as follows: Marketing, Manufacturing Production), and Accounting. The business had grown by ten times, and this growth was creating opportunities for increased sales and some problems in getting systems and processes in place to meet the ever-increasing demand, Several major customers had been complaining that orders were not on time. The customer representative Zhang Wei at the Home Hardware was the most vocal. He would drop into the Mary's Mask Inc. facility to follow up on late orders and hand-carry masks back to the distribution center to get to their stores. Marketing, in turn, became very vocal with manufacturing that they better get the product out the door "pronto" and provide better customer service in meeting orders. This created a lot of conflict and frustration between these two areas, Mary thought some Supply Chain Planning and specific expertise in using the MRP system was required. She had heard that students from Conestoga's Supply Chain and Operations Management Diploma programs were very good at taking a system view approach, figuring out the problems or root causes in a business, and making excellent suggestions for improvement. Aarav Singh, a graduate of the Supply Chain and Operations Management program was hired as a Business Analyst to address this needed expertise. Aarav's first day on the job, he met with the owner and was tasked with finding out why customer delivery dates were not being met. Aarav knew from school that he needed to get to the root cause and not just deal with symptoms. That would be the only way to solve this issue once and for all. He really wanted to make a great impression on his new boss. He walked around the facility and gathered some information. There were no capacity constraints as many people could be subcontracted to complete the sewing when they got behind. They were very responsive to changes and did what it took to get the job done fast. During the pandemic, the other investment made was a larger cutting press to cut the cloth before sewing. Page 1 Juliana Joyst, a graduate of the Accounting diploma at Conestoga, ooked after the company's Accounting and Purchasing functions. She spent one week in Purchasing and then the next in Accounting. The cheques were run every second week, so this seemed to work for her. Juliana Joyst, a graduate of the Accounting diploma at Conestoga, looked after the company's Accounting and Purchasing functions. She spent one week in Purchasing and then the next in Accounting. The cheques were run every second week, so this seemed to work for her. The raw material, cloth, came from a supplier in Woodstock. The supplier had several customers in Waterloo Region and used a company truck every week to deliver in Waterloo Region. It wasn't easy to expedite the cloth-making, but they could rush shipments with a local expediting company, which seemed to happen frequently. The rolls of cloth were 1.37 m wide and could come in lengths ranging from 37-51 meters. The cut masks were 45 meters long by 22 meters wide. It took 0.10 square meters of cloth to make a mask, and Aarav verified that calculation with an engineer to ensure the BOM was accurate. The Production Manager complained that they were always running short of cloth. "Someone is just not doing their job. There was lots of capacity, lots of downtime due to the lack of raw material. A cycle count was performed on the Masks and Cloth at the start of week 7. There were 0 Masks, part number 55687 and 100 m of Cloth. The inventory records were not reconciled. Aarav gathered information on the inputs to MRP so he could analyze what was going on. He thought if he focused on one FG and the raw material Cloth, it would be the best way to get to the root causes of the problems and figure out what was going on. The data gathered follows on the next few pages. Questions 1. Based on the information given, what are the two (2) root causes of Mary's missing customer delivery dates show your work quantitatively and qualitatively Look at all the information that follows and identify what is OK and what is a problem. Hint-Are all 5 MRP inputs accurate WMPS BOM Inu. Balonces Open Orders. Planning Factors - 2 have problems) Garbage in garbage out vs marks) Questions 1. Based on the information given, what are the two (2) root causes of Mary's missing customer delivery dates? Show your work quantitatively and qualitatively. Look at all the information that follows and identify what is OK and what is a problem. Hint- Are all 5 MRP inputs accurate (MPS, BOM, Inv. Balances, Open Orders, Planning Factors - 2 have problems) Garbage in, garbage out. (8 marks) 2. How can you resolve the current issue and make sure the customer order dates will be met? Hint - fix the issues in the short term and the longer-term (4 marks) 3. What procedural changes will you implement to ensure this issue does not happen again? How can you verify what you have put in place is working? Hint - This answer will address the root causes for the long term and have a measurement to ensure what you are proposing is working. (6 marks) 4. Format-Typed, no spelling errors, one question flows after the other. (2 marks) For Bonus Marks (optional) In Week 7, Costco phones to notify Mary's Masks Inc. that they will be forwarding a Purchase Order the following week for an initial order of 4000 masks and are asking for a delivery commitment. Should Mary s Mask accept the order? If so, in which week should they promise 1" delivery? Justify your answer. (2 marks) Page 1 . . Hints/Comments: When you are given a hint, use it... i.e., there are 5 Inputs to MRP - the root causes are found there. Projected Inventory Available: this the projected amount of inventory. It will not match perpetual inventory records unless everything happened according to plan. Think of this like a Budget vs. Bank Account (MRP vs Actual). In this case we have Planned Deliveries, Purchase Orders, and Work Orders. MRP Regeneration: you were given 4 snapshots in time - this does not mean the MRP was only regenerated 4 times in 4 weeks. There are blank columns in the Customer Order Log, Work Order Report, and Purchase Order Report for a reason - use those columns to reconcile the data and get a better understanding of Mary's Masks Inc.'s process and issues, . Mary's Masks Inc. is not a long case (2-3 pages typed), but it is an application of a lot of the theory we have learned this semester, and critical thinking skills are required to figure out the root causes with the information given. Customer Order Log Customer Customer POH Week Ordered Week Promised Quantity Ordered Quantity Shipped 4 1 2 4 Zoniary Home Hardware Jeelos K-W Sales Zoniary Jeelos Home Hardware K-W Sales Home Hardware Zoniary K-W Sales Zoniary K-W Sales Jee os Zonary 50357 28069 39820 7294 50398 39871 29041 7312 29150 50412 7325 50427 7352 39901 50452 6 7 2000 750 2000 1000 1500 2000 750 1000 750 1500 1000 1500 1000 2000- 1500 5 3 5 100 00 00 00 ou un 7 7 5 6 6 Work Order Report Printed Today (Start of Week 7) Part Number: 55687 Release Week 3 Description: Mask Required Release WK Qty 4 2750 Received to Date Order # 175 227 245 Status Closed Closed Open Open 4 5 5 6 3000 4250 3250 267 6 7 Purchase Order Report Printed Today Part Number: Cloth Release Week Order # 220 Description: Cloth Required Release WK Qty 3 400 Received to Date Week 2. 4 4 Status Closed Closed Closed Closed Open Open 4 223 241 250 254 255 5 4 200 400 100 300 6 6 16 6 300 Inventory Records Printed Today Part Number: 55687 Description: Mask Production Received Week 3 Shipped Inventor Adjustment y Balance 0 4 500 2000 4 500 2500 500 4 2000 4 500 0 5 250 250 5 250 0 5 1750 Transaction # Open Inv WO#175 WO#175 CPO#50357 CPO#28069 WO#175 CPO#2806 WO#227 WO#227 CPO#39820 CPO#7294 WO#227 CPO7294 WO=245 WO#245 CPO-50398 CPO=39871 CPO-29041 1750 5 1000 5 2750 750 5 2000 750 6 250 6 250 0 250 750 B000 1500 2000 250 750 3750 2250 250 0 Part Number: Cloth Description: Cloth Required Inventor Week Transaction # to Issue Issued Receipt Adjustment y Balance Allocations 3 Open Iny 50 3 WO#175 275 50 0 225 4 PO# 220 400 400 4 WO#175 225 225 175 WO#227 300 175 0 125 5 PO#228 200 200 5 WO#227 125 125 75 5 WO#245 425 75 0 350 6 PO#241 400 400 6 WO#245 350 350 50 6 WO#267 325 50 0 275 6 PO#250 100 100 Aarav was able to print off the MRP records at the start of each week from week 4-7. This does not mean that is the only time that MRP was run. Past Due 4 6 5 3000 7 1500 3500 Week 4 start of the week's MRP record PART # 55687 PARENT-FG LOT SIZE L4L 1 GROSS REQUIREMENTS LEAD TIME (week 1 SCHED. RECEIPTS ON HAND 0 PROJECTED INVENTORY SAFETY STOCK 0 NET REQUIREMENTS LOW LEVEL CODE 0 PLANNED ORDER RECEIPT PLANNED ORDER RELEASE 2750 2750 0 0 0 0 0 0 1500 0 3000 3000 3000 3500 3500 3500 1500 1500 0 0.1 Past Due 4 5 6 7 300 350 150 0 225 Week 4 start of the week's MRP record PART # Cloth PARENT-55687 LOT SIZE 100 GROSS REQUIREMENTS LEAD TIME (week! 2 ALLOCATIONS ON HAND 0 SCHED. RECEIPTS SAFETY STOCK 50 PROJECTED INVENTORY LOW LEVEL CODE 100 NET REQUIREMENTS PLANNED ORDER RECEIPTI PLANNED ORDER RELEASE 400 175 75 175 125 325 75 75 75 0 200 400 0 100 0 600 100 0 0 8 Past Due 250 250 5 3000 3000 6 4250 Week 5 start of the week's MRP record PART #55687 PARENT-FG LOT SIZE L4L 1 GROSS REQUIREMENTS LEAD TIME (week 1 SCHED. RECEIPTS ON HAND 0 PROJECTED INVENTORY SAFETY STOCK NET REQUIREMENTS LOW LEVEL CODE 0 PUANNED ORDER RECEIPT PLANNED ORDER RELEASE 7 2500 1500 0 0 D D 4250 41250 2500 0 2500 2500 1500 0 1500 1500 0 4250 0.1 Past Due 5 6 7 8 425 250 150 0 125 Week 5 start of the week's MRP record PART # Cloth PARENT-55687 LOT SIZE 100 GROSS REQUIREMENTS LEAD TIME (week 2 ALLOCATIONS ON HAND 0 SCHED. RECEIPTS SAFETY STOCK 50 PROJECTED INVENTORY LOW LEVEL CODE 100 NET REQUIREMENTS PLANNED ORDER RECEIPT PLANNED ORDER RELEASE 200 400 100 75 50 100 50 50 0 150 100 100 0 200 0 200 100 O 0 0 7 9 Past Due 250 250 Week 6 start of the week's MRP record PART # 55687 PARENT- FG LOT SIZE LAL 1 GROSS REQUIREMENTS LEAD TIME (week! 1 SCHED. RECEIPTS ON HAND 0 PROJECTED INVENTORY SAFETY STOCK 0 NET REQUIREMENTS LOW LEVEL CODE 0 PLANNED ORDER RECEIPT PLANNED ORDER RELEASE 8 3500 3250 6 4250 4250 0 0 0 0 0 0 0 3250 3250 3250 3500 3500 3500 0 0 0 0 0.1 Past Due 6 8 7 350 325 9 0 0 350 Week 6 start of the week's MRP record PART # Cloth PARENT-55687 LOT SIZE 100 GROSS REQUIREMENTS LEAD TIME (week 2 ALLOCATIONS ON HAND 0 SCHED. RECEIPTS SAFETY STOCK 50 PROJECTED INVENTORY LOW LEVEL CODE 100 NET REQUIREMENTS PLANNED ORDER RECEIPT PLANNED ORDER RELEASE 400 50 100 125 225 300 0 75 275 300 75 0 75 0 0 600 0 0 0 0 Past Due 7 8 9 10 500 3500 3500 Week 7 start of week's MRP record PART # 55687 PARENT-FG LOT SIZE 4L 1 GROSS REQUIREMENTS LEAD TIME (week 1 SCHED. RECEIPTS ON HAND PROJECTED INVENTORY SAFETY STOCK NET REQUIREMENTS LOW LEVEL CODE PLANNED ORDER RECEPT PLANNED ORDER RELEASE B250 B250 500 @ O 3500 3500 3500 3500 0 0 0 SOND 3500 0.1 7 Past Due 8 9 10 350 350 0 0 275 Week 7 start of week's MRP record PART # Cloth PARENT 55687 LOT SIZE 100 GROSS REQUIREMENTS LEAD TIME week 2 ALLOCATIONS ON HAND 100 SCHED. RECEIPTS SAFETY STOCK 50 PROJECTED INVENTORY LOW LEVEL CODE 0 NET REQUIREMENTS PLANNED ORDER RECEIPT PLANNED ORDER RELEASE 0 300 125 300 75 125 125 125 0 0 0 325 400 0 0 0 0 400 0 0 0 Mary's Masks Inc. OPER2210 - MRP Case Study Hand-In - Winter 2021. Mary's Mask Inc. had started as a small business in the owner's house, making pet coats and bandanas, Once the COVID pandemic started, Mary realized that she could pivot her business to making cloth masks that matched the pet items. Her business grew exponentially, which required her to move out of her house to a new larger location. The owner had previously taken some ASCM(APICS) review courses to understand good planning and control systems. She bought a small computerized software package to automate the material ordering processes. The modules they had implemented were Inventory, Purchasing, and MRP. Other modules were going to be implemented in the coming months. The implementation had gone well, and the software appeared to be working well. The customer base had been growing, and Costco had started to make some inquiries of Mary's Mask Inc. supplying them with cloth masks. The sky was the limit for sales, When Mary's Mask Inc. was small, the entrepreneur easily satisfied customer demand as she did everything herself. As the company grew larger meeting customer orders on a timely basis proved to be more difficult. In the last year, she hired several people who specialized in various parts of the business as follows: Marketing, Manufacturing Production), and Accounting. The business had grown by ten times, and this growth was creating opportunities for increased sales and some problems in getting systems and processes in place to meet the ever-increasing demand, Several major customers had been complaining that orders were not on time. The customer representative Zhang Wei at the Home Hardware was the most vocal. He would drop into the Mary's Mask Inc. facility to follow up on late orders and hand-carry masks back to the distribution center to get to their stores. Marketing, in turn, became very vocal with manufacturing that they better get the product out the door "pronto" and provide better customer service in meeting orders. This created a lot of conflict and frustration between these two areas, Mary thought some Supply Chain Planning and specific expertise in using the MRP system was required. She had heard that students from Conestoga's Supply Chain and Operations Management Diploma programs were very good at taking a system view approach, figuring out the problems or root causes in a business, and making excellent suggestions for improvement. Aarav Singh, a graduate of the Supply Chain and Operations Management program was hired as a Business Analyst to address this needed expertise. Aarav's first day on the job, he met with the owner and was tasked with finding out why customer delivery dates were not being met. Aarav knew from school that he needed to get to the root cause and not just deal with symptoms. That would be the only way to solve this issue once and for all. He really wanted to make a great impression on his new boss. He walked around the facility and gathered some information. There were no capacity constraints as many people could be subcontracted to complete the sewing when they got behind. They were very responsive to changes and did what it took to get the job done fast. During the pandemic, the other investment made was a larger cutting press to cut the cloth before sewing. Page 1 Juliana Joyst, a graduate of the Accounting diploma at Conestoga, ooked after the company's Accounting and Purchasing functions. She spent one week in Purchasing and then the next in Accounting. The cheques were run every second week, so this seemed to work for her. Juliana Joyst, a graduate of the Accounting diploma at Conestoga, looked after the company's Accounting and Purchasing functions. She spent one week in Purchasing and then the next in Accounting. The cheques were run every second week, so this seemed to work for her. The raw material, cloth, came from a supplier in Woodstock. The supplier had several customers in Waterloo Region and used a company truck every week to deliver in Waterloo Region. It wasn't easy to expedite the cloth-making, but they could rush shipments with a local expediting company, which seemed to happen frequently. The rolls of cloth were 1.37 m wide and could come in lengths ranging from 37-51 meters. The cut masks were 45 meters long by 22 meters wide. It took 0.10 square meters of cloth to make a mask, and Aarav verified that calculation with an engineer to ensure the BOM was accurate. The Production Manager complained that they were always running short of cloth. "Someone is just not doing their job. There was lots of capacity, lots of downtime due to the lack of raw material. A cycle count was performed on the Masks and Cloth at the start of week 7. There were 0 Masks, part number 55687 and 100 m of Cloth. The inventory records were not reconciled. Aarav gathered information on the inputs to MRP so he could analyze what was going on. He thought if he focused on one FG and the raw material Cloth, it would be the best way to get to the root causes of the problems and figure out what was going on. The data gathered follows on the next few pages. Questions 1. Based on the information given, what are the two (2) root causes of Mary's missing customer delivery dates show your work quantitatively and qualitatively Look at all the information that follows and identify what is OK and what is a problem. Hint-Are all 5 MRP inputs accurate WMPS BOM Inu. Balonces Open Orders. Planning Factors - 2 have problems) Garbage in garbage out vs marks) Questions 1. Based on the information given, what are the two (2) root causes of Mary's missing customer delivery dates? Show your work quantitatively and qualitatively. Look at all the information that follows and identify what is OK and what is a problem. Hint- Are all 5 MRP inputs accurate (MPS, BOM, Inv. Balances, Open Orders, Planning Factors - 2 have problems) Garbage in, garbage out. (8 marks) 2. How can you resolve the current issue and make sure the customer order dates will be met? Hint - fix the issues in the short term and the longer-term (4 marks) 3. What procedural changes will you implement to ensure this issue does not happen again? How can you verify what you have put in place is working? Hint - This answer will address the root causes for the long term and have a measurement to ensure what you are proposing is working. (6 marks) 4. Format-Typed, no spelling errors, one question flows after the other. (2 marks) For Bonus Marks (optional) In Week 7, Costco phones to notify Mary's Masks Inc. that they will be forwarding a Purchase Order the following week for an initial order of 4000 masks and are asking for a delivery commitment. Should Mary s Mask accept the order? If so, in which week should they promise 1" delivery? Justify your answer. (2 marks) Page 1 . . Hints/Comments: When you are given a hint, use it... i.e., there are 5 Inputs to MRP - the root causes are found there. Projected Inventory Available: this the projected amount of inventory. It will not match perpetual inventory records unless everything happened according to plan. Think of this like a Budget vs. Bank Account (MRP vs Actual). In this case we have Planned Deliveries, Purchase Orders, and Work Orders. MRP Regeneration: you were given 4 snapshots in time - this does not mean the MRP was only regenerated 4 times in 4 weeks. There are blank columns in the Customer Order Log, Work Order Report, and Purchase Order Report for a reason - use those columns to reconcile the data and get a better understanding of Mary's Masks Inc.'s process and issues, . Mary's Masks Inc. is not a long case (2-3 pages typed), but it is an application of a lot of the theory we have learned this semester, and critical thinking skills are required to figure out the root causes with the information given. Customer Order Log Customer Customer POH Week Ordered Week Promised Quantity Ordered Quantity Shipped 4 1 2 4 Zoniary Home Hardware Jeelos K-W Sales Zoniary Jeelos Home Hardware K-W Sales Home Hardware Zoniary K-W Sales Zoniary K-W Sales Jee os Zonary 50357 28069 39820 7294 50398 39871 29041 7312 29150 50412 7325 50427 7352 39901 50452 6 7 2000 750 2000 1000 1500 2000 750 1000 750 1500 1000 1500 1000 2000- 1500 5 3 5 100 00 00 00 ou un 7 7 5 6 6 Work Order Report Printed Today (Start of Week 7) Part Number: 55687 Release Week 3 Description: Mask Required Release WK Qty 4 2750 Received to Date Order # 175 227 245 Status Closed Closed Open Open 4 5 5 6 3000 4250 3250 267 6 7 Purchase Order Report Printed Today Part Number: Cloth Release Week Order # 220 Description: Cloth Required Release WK Qty 3 400 Received to Date Week 2. 4 4 Status Closed Closed Closed Closed Open Open 4 223 241 250 254 255 5 4 200 400 100 300 6 6 16 6 300 Inventory Records Printed Today Part Number: 55687 Description: Mask Production Received Week 3 Shipped Inventor Adjustment y Balance 0 4 500 2000 4 500 2500 500 4 2000 4 500 0 5 250 250 5 250 0 5 1750 Transaction # Open Inv WO#175 WO#175 CPO#50357 CPO#28069 WO#175 CPO#2806 WO#227 WO#227 CPO#39820 CPO#7294 WO#227 CPO7294 WO=245 WO#245 CPO-50398 CPO=39871 CPO-29041 1750 5 1000 5 2750 750 5 2000 750 6 250 6 250 0 250 750 B000 1500 2000 250 750 3750 2250 250 0 Part Number: Cloth Description: Cloth Required Inventor Week Transaction # to Issue Issued Receipt Adjustment y Balance Allocations 3 Open Iny 50 3 WO#175 275 50 0 225 4 PO# 220 400 400 4 WO#175 225 225 175 WO#227 300 175 0 125 5 PO#228 200 200 5 WO#227 125 125 75 5 WO#245 425 75 0 350 6 PO#241 400 400 6 WO#245 350 350 50 6 WO#267 325 50 0 275 6 PO#250 100 100 Aarav was able to print off the MRP records at the start of each week from week 4-7. This does not mean that is the only time that MRP was run. Past Due 4 6 5 3000 7 1500 3500 Week 4 start of the week's MRP record PART # 55687 PARENT-FG LOT SIZE L4L 1 GROSS REQUIREMENTS LEAD TIME (week 1 SCHED. RECEIPTS ON HAND 0 PROJECTED INVENTORY SAFETY STOCK 0 NET REQUIREMENTS LOW LEVEL CODE 0 PLANNED ORDER RECEIPT PLANNED ORDER RELEASE 2750 2750 0 0 0 0 0 0 1500 0 3000 3000 3000 3500 3500 3500 1500 1500 0 0.1 Past Due 4 5 6 7 300 350 150 0 225 Week 4 start of the week's MRP record PART # Cloth PARENT-55687 LOT SIZE 100 GROSS REQUIREMENTS LEAD TIME (week! 2 ALLOCATIONS ON HAND 0 SCHED. RECEIPTS SAFETY STOCK 50 PROJECTED INVENTORY LOW LEVEL CODE 100 NET REQUIREMENTS PLANNED ORDER RECEIPTI PLANNED ORDER RELEASE 400 175 75 175 125 325 75 75 75 0 200 400 0 100 0 600 100 0 0 8 Past Due 250 250 5 3000 3000 6 4250 Week 5 start of the week's MRP record PART #55687 PARENT-FG LOT SIZE L4L 1 GROSS REQUIREMENTS LEAD TIME (week 1 SCHED. RECEIPTS ON HAND 0 PROJECTED INVENTORY SAFETY STOCK NET REQUIREMENTS LOW LEVEL CODE 0 PUANNED ORDER RECEIPT PLANNED ORDER RELEASE 7 2500 1500 0 0 D D 4250 41250 2500 0 2500 2500 1500 0 1500 1500 0 4250 0.1 Past Due 5 6 7 8 425 250 150 0 125 Week 5 start of the week's MRP record PART # Cloth PARENT-55687 LOT SIZE 100 GROSS REQUIREMENTS LEAD TIME (week 2 ALLOCATIONS ON HAND 0 SCHED. RECEIPTS SAFETY STOCK 50 PROJECTED INVENTORY LOW LEVEL CODE 100 NET REQUIREMENTS PLANNED ORDER RECEIPT PLANNED ORDER RELEASE 200 400 100 75 50 100 50 50 0 150 100 100 0 200 0 200 100 O 0 0 7 9 Past Due 250 250 Week 6 start of the week's MRP record PART # 55687 PARENT- FG LOT SIZE LAL 1 GROSS REQUIREMENTS LEAD TIME (week! 1 SCHED. RECEIPTS ON HAND 0 PROJECTED INVENTORY SAFETY STOCK 0 NET REQUIREMENTS LOW LEVEL CODE 0 PLANNED ORDER RECEIPT PLANNED ORDER RELEASE 8 3500 3250 6 4250 4250 0 0 0 0 0 0 0 3250 3250 3250 3500 3500 3500 0 0 0 0 0.1 Past Due 6 8 7 350 325 9 0 0 350 Week 6 start of the week's MRP record PART # Cloth PARENT-55687 LOT SIZE 100 GROSS REQUIREMENTS LEAD TIME (week 2 ALLOCATIONS ON HAND 0 SCHED. RECEIPTS SAFETY STOCK 50 PROJECTED INVENTORY LOW LEVEL CODE 100 NET REQUIREMENTS PLANNED ORDER RECEIPT PLANNED ORDER RELEASE 400 50 100 125 225 300 0 75 275 300 75 0 75 0 0 600 0 0 0 0 Past Due 7 8 9 10 500 3500 3500 Week 7 start of week's MRP record PART # 55687 PARENT-FG LOT SIZE 4L 1 GROSS REQUIREMENTS LEAD TIME (week 1 SCHED. RECEIPTS ON HAND PROJECTED INVENTORY SAFETY STOCK NET REQUIREMENTS LOW LEVEL CODE PLANNED ORDER RECEPT PLANNED ORDER RELEASE B250 B250 500 @ O 3500 3500 3500 3500 0 0 0 SOND 3500 0.1 7 Past Due 8 9 10 350 350 0 0 275 Week 7 start of week's MRP record PART # Cloth PARENT 55687 LOT SIZE 100 GROSS REQUIREMENTS LEAD TIME week 2 ALLOCATIONS ON HAND 100 SCHED. RECEIPTS SAFETY STOCK 50 PROJECTED INVENTORY LOW LEVEL CODE 0 NET REQUIREMENTS PLANNED ORDER RECEIPT PLANNED ORDER RELEASE 0 300 125 300 75 125 125 125 0 0 0 325 400 0 0 0 0 400 0 0 0

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock