Question: Mastery Problem: Job Order Costing (Basic) A job order costing system is used when a company produces a product or provides a service that is

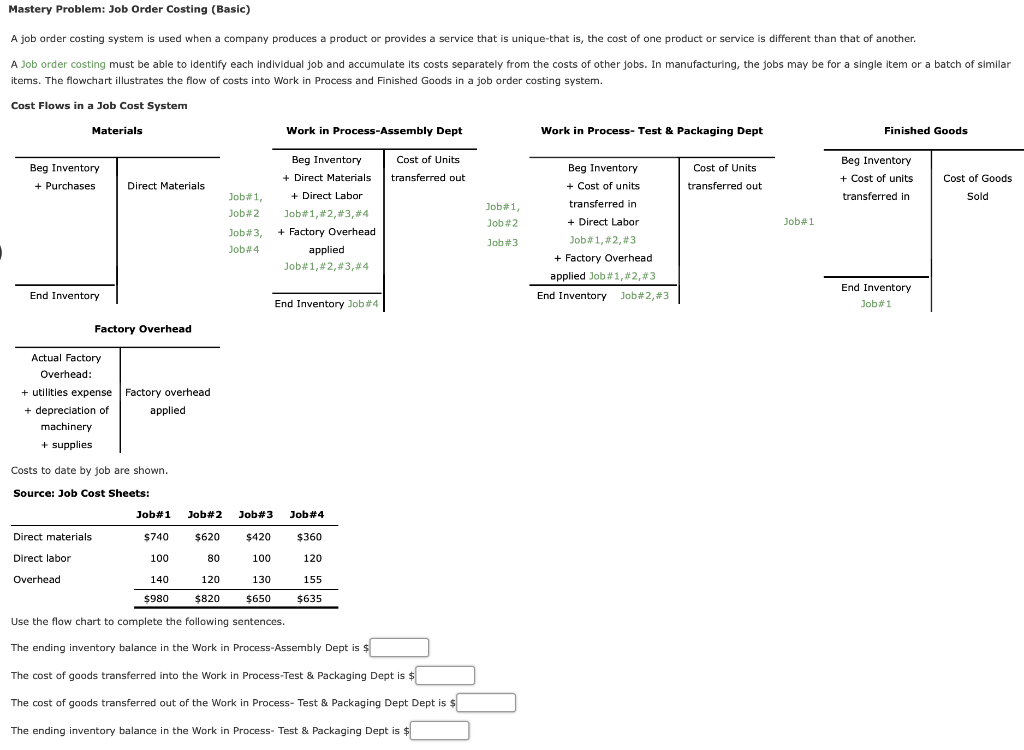

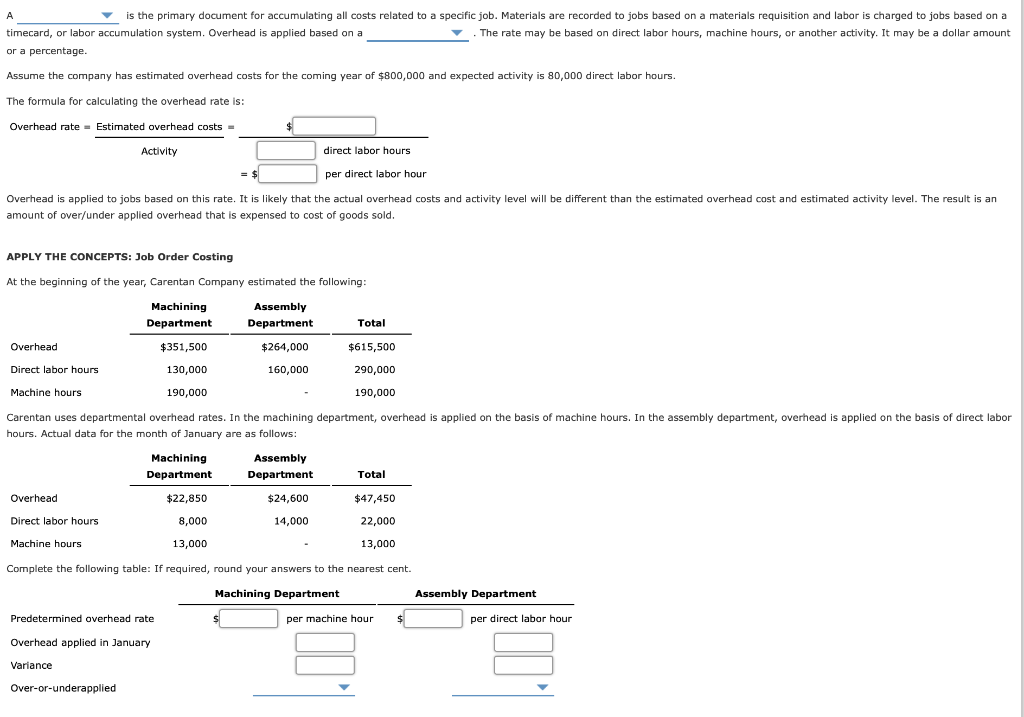

Mastery Problem: Job Order Costing (Basic) A job order costing system is used when a company produces a product or provides a service that is unique-that is, the cost of one product or service is different than that of another. A Job order costing must be able to identify each individual job and accumulate its costs separately from the costs of other jobs. In manufacturing, the jobs may be for a single item or a batch of similar items. The flowchart illustrates the flow of costs into Work in Process and Finished Goods in a job order costing system. Cost Flows in a Job Cost System Materials Work in Process-Assembly Dept Work in Process-Test & Packaging Dept Finished Goods Beg Inventory +Direct Materials + Direct Labor Job#1,#2,#3,#4 + Factory Overhead applied Job#1,#2,#3,#4 Cost of Units Beg Inventory + Cost of units transferred in Beg Inventory Beg Inventory +Cost of units transferred in + Direct Labor Job#1, #2,#3 + Factory Overhead applied Job #1,#2,#3 End Inventory Job# 2,#3 Cost of Units transferred out Cost of Goods Direct Materials transferred out Sold Job# 1, Job# 2 Job#3, Job#4 Job# 1 Job #2 Job#3 Job# 1 End Inventory Job#1 End Inventory End Inventory Job #4 Factory Overhead Actual Factory Overhead: + utilities expense Factory overhead + depreciation of machinery +supplies applied Costs to date by job are shown Source: Job Cost Sheets: Direct materials Direct labor Overhead Job# 1 Job# 2 $740$620 80 120 $820 100 140 $980 Job# 3 $420 100 130 $650 Job#4 $360 120 155 $635 Use the flow chart to complete the following sentences. The ending inventory balance in the Work in Process-Assembly Dept is The cost of goods transferred into the Work in Process-Test & Packaging Dept is $ The cost of goods transferred out of the Work in Process- Test & Packaging Dept Dept is $ The ending inventory balance in the Work in Process- Test & Packaging Dept is $ is the primary document for accumulating all costs related to a specific job. Materials are recorded to jobs based on a materials requisition and labor is charged to jobs based on a The rate may be based on direct labor hours, machine hours, or another activity. It may be a dollar amount timecard, or labor accumulation system. Overhead is applied based on a or a percentage. Assume the company has estimated overhead costs for the coming year of $800,000 and expected activity is 80,000 direct labor hours The formula for calculating the overhead rate is: Overhead rateEstimated overhead costs direct labor hours Activity per direct labor hour Overhead is applied to jobs based on this rate. It is likely that the actual overhead costs and activity level will be different than the estimated overhead cost and estimated activity level. The result is an amount of over/under applied overhead that is expensed to cost of goods sold APPLY THE CONCEPTS: Job Order Costing At the beginning of the year, Carentan Company estimated the following Machining Department $351,500 130,000 190,000 Assembly Department $264,000 160,000 Total $615,500 290,000 190,000 Direct labor hours Machine hours Carentan uses departmental overhead rates. In the machining department, overhead is applied on the basis of machine hours. In the assembly department, overhead is applied on the basis of direct labor hours. Actual data for the month of January are as follows Machining Department $22,850 8,000 13,000 Assembly Department Total $24,600 $47,450 Direct labor hours Machine hours Complete the following table: If required, round your answers to the nearest cent. 14,000 22,000 13,000 Machining Department Assembly Department Predetermined overhead rate Overhead applied in January Variance Over-or-underapplied per machine hour per direct labor hour Mastery Problem: Job Order Costing (Basic) A job order costing system is used when a company produces a product or provides a service that is unique-that is, the cost of one product or service is different than that of another. A Job order costing must be able to identify each individual job and accumulate its costs separately from the costs of other jobs. In manufacturing, the jobs may be for a single item or a batch of similar items. The flowchart illustrates the flow of costs into Work in Process and Finished Goods in a job order costing system. Cost Flows in a Job Cost System Materials Work in Process-Assembly Dept Work in Process-Test & Packaging Dept Finished Goods Beg Inventory +Direct Materials + Direct Labor Job#1,#2,#3,#4 + Factory Overhead applied Job#1,#2,#3,#4 Cost of Units Beg Inventory + Cost of units transferred in Beg Inventory Beg Inventory +Cost of units transferred in + Direct Labor Job#1, #2,#3 + Factory Overhead applied Job #1,#2,#3 End Inventory Job# 2,#3 Cost of Units transferred out Cost of Goods Direct Materials transferred out Sold Job# 1, Job# 2 Job#3, Job#4 Job# 1 Job #2 Job#3 Job# 1 End Inventory Job#1 End Inventory End Inventory Job #4 Factory Overhead Actual Factory Overhead: + utilities expense Factory overhead + depreciation of machinery +supplies applied Costs to date by job are shown Source: Job Cost Sheets: Direct materials Direct labor Overhead Job# 1 Job# 2 $740$620 80 120 $820 100 140 $980 Job# 3 $420 100 130 $650 Job#4 $360 120 155 $635 Use the flow chart to complete the following sentences. The ending inventory balance in the Work in Process-Assembly Dept is The cost of goods transferred into the Work in Process-Test & Packaging Dept is $ The cost of goods transferred out of the Work in Process- Test & Packaging Dept Dept is $ The ending inventory balance in the Work in Process- Test & Packaging Dept is $ is the primary document for accumulating all costs related to a specific job. Materials are recorded to jobs based on a materials requisition and labor is charged to jobs based on a The rate may be based on direct labor hours, machine hours, or another activity. It may be a dollar amount timecard, or labor accumulation system. Overhead is applied based on a or a percentage. Assume the company has estimated overhead costs for the coming year of $800,000 and expected activity is 80,000 direct labor hours The formula for calculating the overhead rate is: Overhead rateEstimated overhead costs direct labor hours Activity per direct labor hour Overhead is applied to jobs based on this rate. It is likely that the actual overhead costs and activity level will be different than the estimated overhead cost and estimated activity level. The result is an amount of over/under applied overhead that is expensed to cost of goods sold APPLY THE CONCEPTS: Job Order Costing At the beginning of the year, Carentan Company estimated the following Machining Department $351,500 130,000 190,000 Assembly Department $264,000 160,000 Total $615,500 290,000 190,000 Direct labor hours Machine hours Carentan uses departmental overhead rates. In the machining department, overhead is applied on the basis of machine hours. In the assembly department, overhead is applied on the basis of direct labor hours. Actual data for the month of January are as follows Machining Department $22,850 8,000 13,000 Assembly Department Total $24,600 $47,450 Direct labor hours Machine hours Complete the following table: If required, round your answers to the nearest cent. 14,000 22,000 13,000 Machining Department Assembly Department Predetermined overhead rate Overhead applied in January Variance Over-or-underapplied per machine hour per direct labor hour

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts