Question: Material Requirements Planning Assignment The following table lists the components needed to assemble an end item, lead times in weeks), quantities on hand, and scheduled

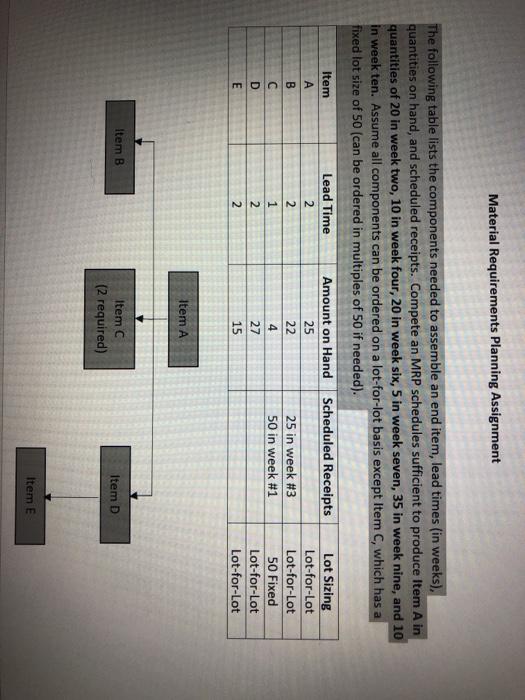

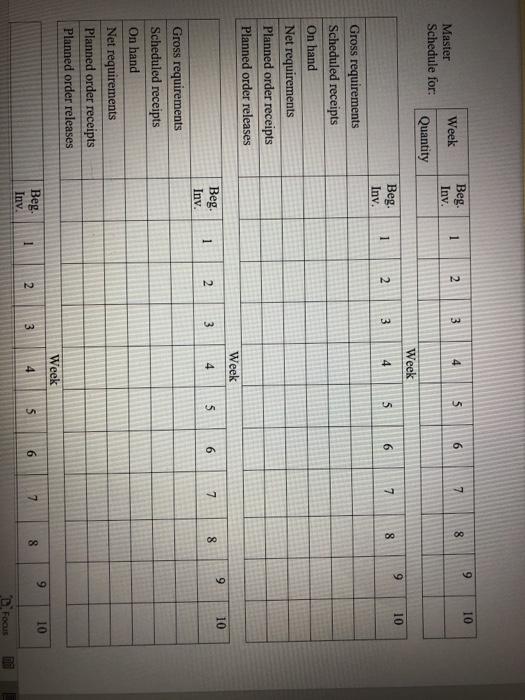

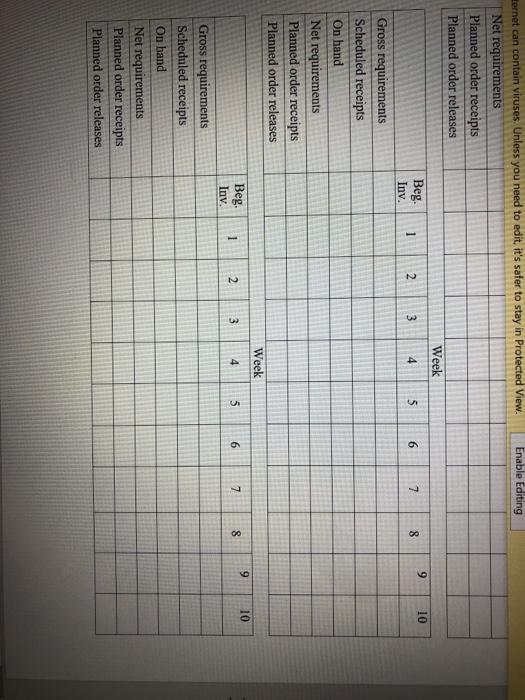

Material Requirements Planning Assignment The following table lists the components needed to assemble an end item, lead times in weeks), quantities on hand, and scheduled receipts. Compete an MRP schedules sufficient to produce Item A in quantities of 20 in week two, 10 in week four, 20 in week six, 5 in week seven, 35 in week nine, and 10 in week ten. Assume all components can be ordered on a lot-for-lot basis except Item C, which has a fixed lot size of 50 (can be ordered in multiples of 50 if needed). Item B Lead Time 2 2 1 2 2 Amount on Hand Scheduled Receipts 25 22 25 in week #3 4 50 in week #1 27 15 Lot Sizing Lot-for-Lot Lot-for-Lot 50 Fixed Lot-for-Lot Lot-for-Lot D E Item A Item B Item C (2 required) Item D Item E 9 10 1 Beg. Inv. 2 3 Week 3 5 4 6 7 00 Master Schedule for: Quantity Week 9 10 Beg Inv. 1 2 3 4 5 6 7 8 Gross requirements Scheduled receipts On hand Net requirements Planned order receipts Planned order releases Week 9 10 1 2 Beg. Inv. 4 5 6 7 00 Gross requirements Scheduled receipts On hand Net requirements Planned order receipts Planned order releases Week 9 10 Beg. . 1 2 3 4 5 6 7 8 Focus Enable Editing 9 10 6 7 8 ternet can contain viruses. Unless you need to edit, it's safer to stay in Protected View. Net requirements Planned order receipts Planned order releases Week Beg. 1 2 3 4 5 Inv. Gross requirements Scheduled receipts On hand Net requirements Planned order receipts Planned order releases Week Beg. 1 2 4 5 Inv. Gross requirements Scheduled receipts On hand Net requirements Planned order receipts Planned order releases 9 10 en 6 7 oc Material Requirements Planning Assignment The following table lists the components needed to assemble an end item, lead times in weeks), quantities on hand, and scheduled receipts. Compete an MRP schedules sufficient to produce Item A in quantities of 20 in week two, 10 in week four, 20 in week six, 5 in week seven, 35 in week nine, and 10 in week ten. Assume all components can be ordered on a lot-for-lot basis except Item C, which has a fixed lot size of 50 (can be ordered in multiples of 50 if needed). Item B Lead Time 2 2 1 2 2 Amount on Hand Scheduled Receipts 25 22 25 in week #3 4 50 in week #1 27 15 Lot Sizing Lot-for-Lot Lot-for-Lot 50 Fixed Lot-for-Lot Lot-for-Lot D E Item A Item B Item C (2 required) Item D Item E 9 10 1 Beg. Inv. 2 3 Week 3 5 4 6 7 00 Master Schedule for: Quantity Week 9 10 Beg Inv. 1 2 3 4 5 6 7 8 Gross requirements Scheduled receipts On hand Net requirements Planned order receipts Planned order releases Week 9 10 1 2 Beg. Inv. 4 5 6 7 00 Gross requirements Scheduled receipts On hand Net requirements Planned order receipts Planned order releases Week 9 10 Beg. . 1 2 3 4 5 6 7 8 Focus Enable Editing 9 10 6 7 8 ternet can contain viruses. Unless you need to edit, it's safer to stay in Protected View. Net requirements Planned order receipts Planned order releases Week Beg. 1 2 3 4 5 Inv. Gross requirements Scheduled receipts On hand Net requirements Planned order receipts Planned order releases Week Beg. 1 2 4 5 Inv. Gross requirements Scheduled receipts On hand Net requirements Planned order receipts Planned order releases 9 10 en 6 7 oc