Question: Max 250 words professional words for each question. Please add references and citation if answering from your own knowledge. Question 3 Outline three methods one

Max 250 words professional words for each question. Please add references and citation if answering from your own knowledge.

Question 3

Outline three methods one can do to monitor quality.

Question 4

Outline the phases of developing a strategy.

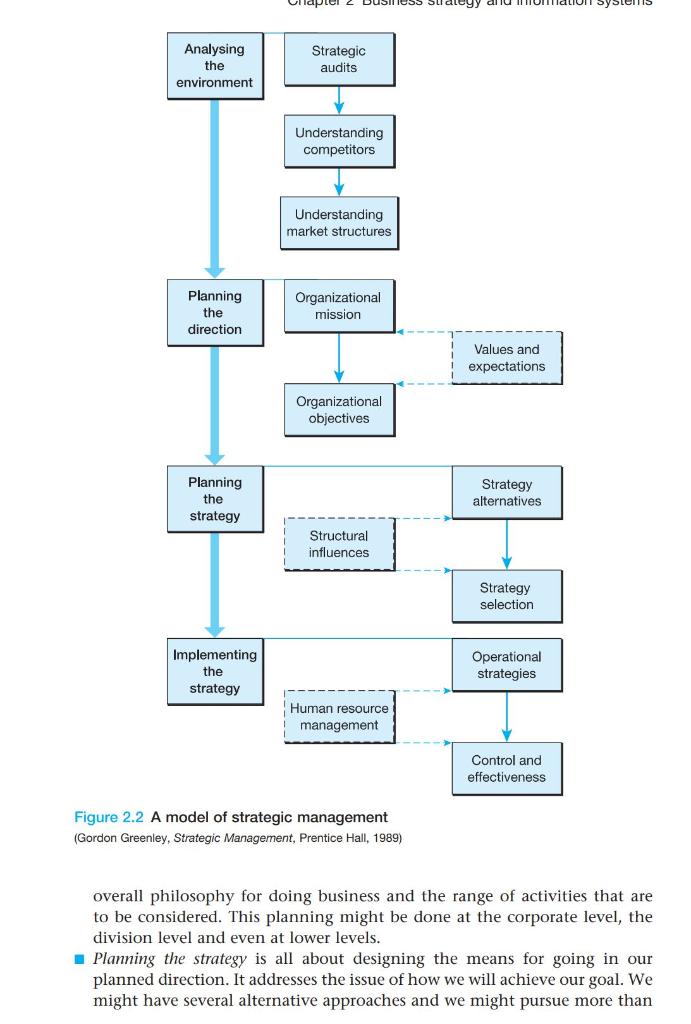

11.4.3 Methods for monitoring quality Various methods exist for conducting quality control reviews, some rather informal and others highly structured. In choosing one, the guiding idea should be the usual touchstone of appropriateness. Whatever approach is taken, the review process must be planned. The reviewers must be clear about: The criteria to be applied. The definitions of pass or fail for the items reviewed. Among the approaches you might consider are the following. Self-checking This really supports the total quality management (TQM) theme and relies on the author of the work having a good understanding of the requirement and also of the skills and techniques needed to meet it. The approach is best suited to more experienced team members who should, as with any other check, formally record their reviews. The big disadvantage with self-checking is that, if someone has misunderstood something in, say, a design document, they will continue to labour under the same misapprehension during the checking process and the defect will not be discovered. For this reason, one of the other forms of check should be used in areas of known criticality and occasionally elsewhere to verify the self-checking procedure. Team leader Here, a team member's supervisor is responsible for checking that work meets reviews its specification and conforms to any requisite standards. If defects are identified, corrective work is undertaken and the work is then reinspected. This method is useful when reviews of work are to be linked to coaching - as will often be the case for junior staff. The problem is that it is only as effective as the supervisor's ability to spot problems and, of course, the team leader may not in fact be as skilled as the author in the particular discipline or technique involved. In addition, bottlenecks can occur with this method, as all checking has to be undertaken by one person; this is particularly the case with projects that are using fast programming methods where programmer productivity can outstrip the ability of the team leader to review the work. Peer reviews This is similar in principle to a team leader review in that one person is check- ing the work of another. Team leader review and peer review can be used in tandem, with the team leader in effect sharing the review work with one of the more experienced team members. Peer review does, of course, rely on the ability of the reviewer to spot defects, and some people are better at this than others. There is a special danger for the project manager to watch for with peer reviews: that of rivalry or one-upmanship between the author and reviewer. They may need reminding that the objective is not to score points off each other but to produce a high-quality product. In a multidisciplinary team, where the team leader does not have expertise in the area to be reviewed, peer review may be the only practical way of conducting quality control. Walkthroughs Conducting a walkthrough, which involves a review by a group of people, can prove very effective, as the skills, knowledge and eyesight (for spotting errors) of a number of people are brought to bear. Walkthroughs do, however, require good organization so that everyone concerned is clear about their objectives and has the necessary documentation available early enough for proper study. In addition, to keep review meetings moving forward and to stop them stray- ing from the point, good chairmanship is essential. It is particularly important in walkthroughs to stick to the identification of problems and to avoid trying to find solutions. Obviously, if a solution does emerge immediately it would be silly to discard it; but since, in meetings, the length of time spent in dis- cussion tends to rise exponentially with the number present, too many ideas for solutions will soon get the meeting completely bogged down. Finally, since reviewing is an intensive activity, meetings should be time-limited - say to a maximum of one or two hours. If the review cannot be completed in that time, it will be much more productive to adjourn and reconvene than to continue with the current meeting. Fagan Fagan inspections are a formalized form of walkthrough, named after Michael inspections Fagan who devised the technique for IBM. With this method, the author of a piece of work reports to the project manager that it is complete and ready for checking. This triggers a six-stage review process: Planning. A trained Fagan 'moderator' organizes the inspection, nominating people for the roles of inspector, reader and scribe and defining the date, duration and purpose of the meeting. Overview. This optional meeting can be used to provide background informa- tion on the work or on the Fagan process or to assign particular inspection tasks to individuals. Preparation. Individuals prepare for the inspection by examining the material and developing their understanding prior to the review. Meeting. This is very structured and chaired by the moderator. The reader paraphrases the item; each inspector, including the author and moderator, reports defects in the item and these are recorded by the scribe. Rework. The author takes the list of defects and, having corrected them, categorizes them by severity and type. Follow-up. A reviewer, nominated by the moderator, checks that the rework is complete and that the defects have been categorized correctly. The data resulting from the inspection is recorded on a database and the moderator signs off the inspection. The compilation of statistics is an important part of the Fagan process, since they can be used to: Measure the cost of the inspection. Produce defect rates for the project. Identify 'hot spots' in a project for more intensive management. Predict the effort required for quality management. Disadvantages cited of the Fagan technique are that training is required in the various roles - especially those of moderator and inspector - and that inspections are time-consuming and expensive. Whilst there is some truth in both of these claims, it must be remembered that the costs of not discovering problems early enough usually outweigh the costs of thorough checking. External review It may sometimes be a good idea to request a review of work from a body or individual outside the project team. This could be by a quality assurance department or simply from an expert in the work being undertaken. External reviews may be a requirement of the contract or they may be imposed as part of an ISO 11001 conformance procedure (see Chapter 14 for more on this). The principal disadvantage of an external review is probably cost, but, on a large project at least, the plans should allow some margin for it. There is an 200 additional problem in that the reviewer will not have the same familiarity with the material as will members of the project team, so an external review is likely to take longer. The obverse of this is that the external person approaches the review without any preconceptions and the resultant objectivity should improve the effectiveness of the review. 2.3 Developing a strategy Knowing about strategy is useful only if we need to understand the strategy of the organization for which we are developing new systems. To understand that strategy, it is helpful if we are clear, at least in outline, about how strategies are developed. If we look at the stages we go through when making a decision, we first of all: Investigate the situation to collect as much data as we can about the facts of the case, and people's views and feelings about them. Then we develop some alternative courses of action based on what we know about the situation under review. Next we evaluate these decisions in terms of their likely outcomes and consequences. Then we choose the decision to be implemented on the basis of the outcomes or consequences. We take account here as well of the likely risks associated with our choice. Finally, we implement our decision or solution and follow it up. We can use this simple process to help us to develop a model of strategic management. Referring to Greenley's model in Figure 2.2: Analysing the environment is concerned with investigating the internal and external environments and developing a comprehensive understanding of our business, its strengths and weaknesses, our competitors and the market within which we all operate. Planning the direction determines the future that we want for our business. We might create a vision for the kind of business we want to be, our 18 tyy Analysing the environment Strategic audits Understanding competitors Understanding market structures Planning the direction Organizational mission Values and expectations Organizational objectives Planning the strategy Strategy alternatives Structural influences Strategy selection Implementing the strategy Operational strategies Human resource management Control and effectiveness Figure 2.2 A model of strategic management (Gordon Greenley, Strategic Management, Prentice Hall, 1989) overall philosophy for doing business and the range of activities that are to be considered. This planning might be done at the corporate level, the division level and even at lower levels. Planning the strategy is all about designing the means for going in our planned direction. It addresses the issue of how we will achieve our goal. We might have several alternative approaches and we might pursue more than

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock