Question: method doesnt matter just need right answer please ill give thunbs up this was also part of question sorry Blazer Panels produces four different types

method doesnt matter just need right answer please ill give thunbs up

this was also part of question sorry

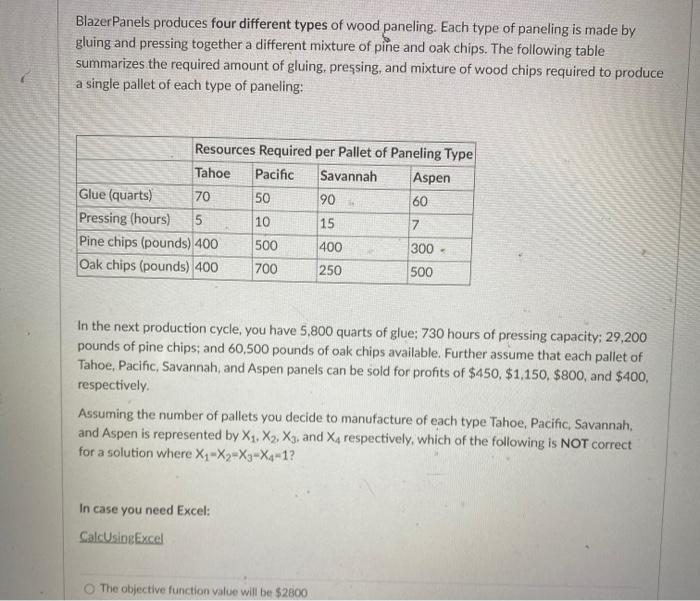

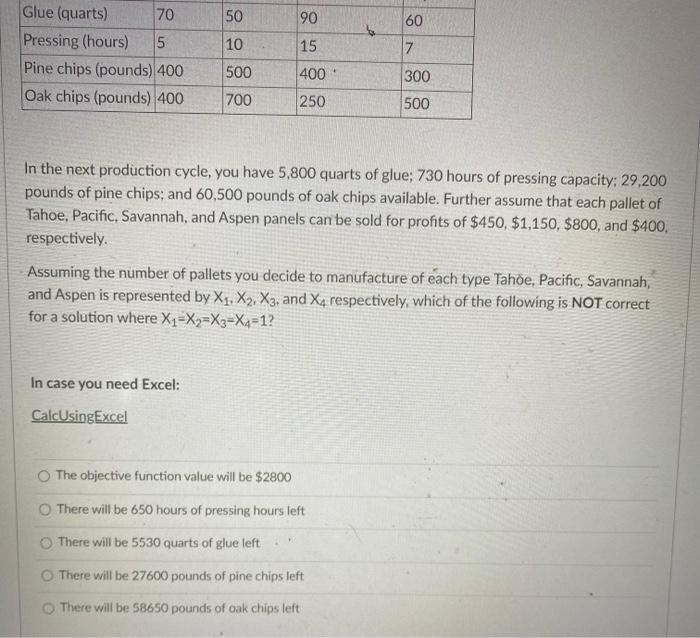

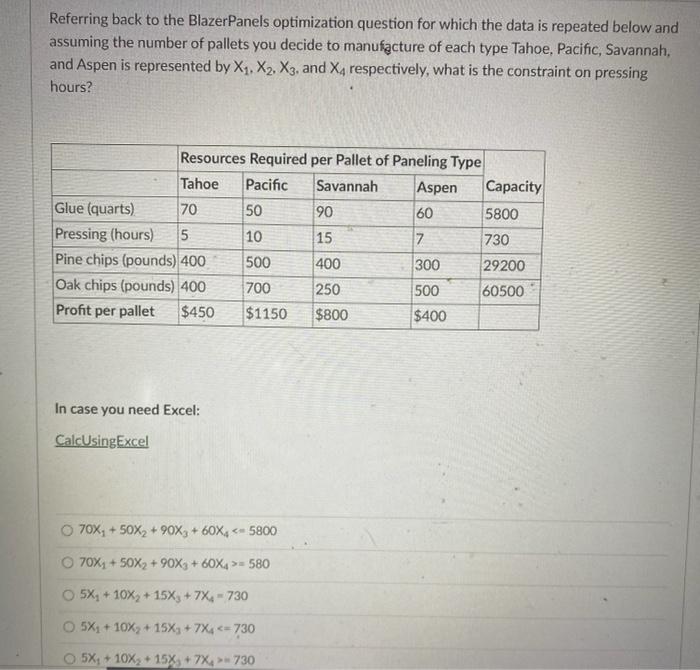

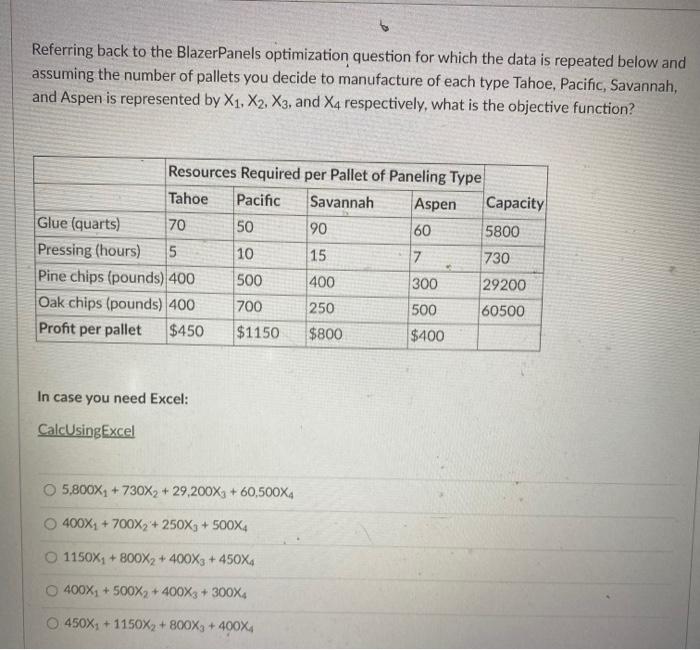

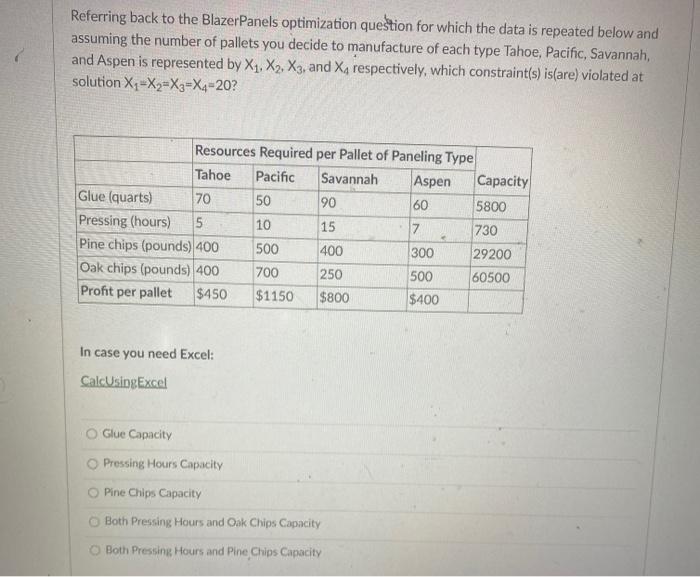

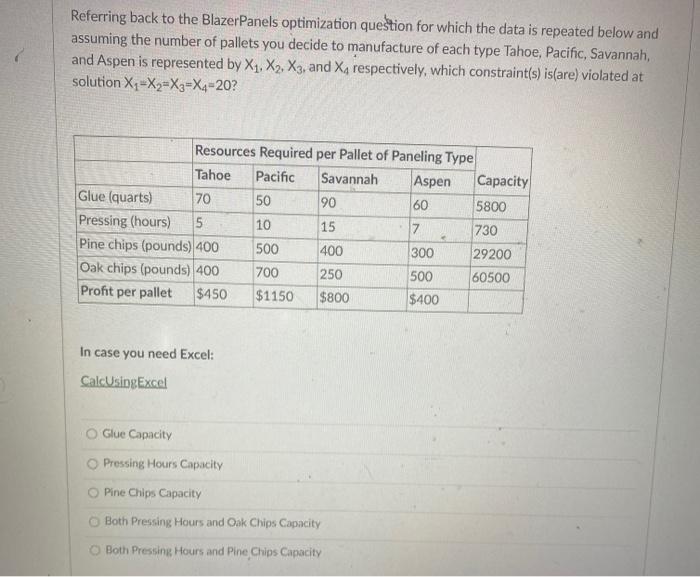

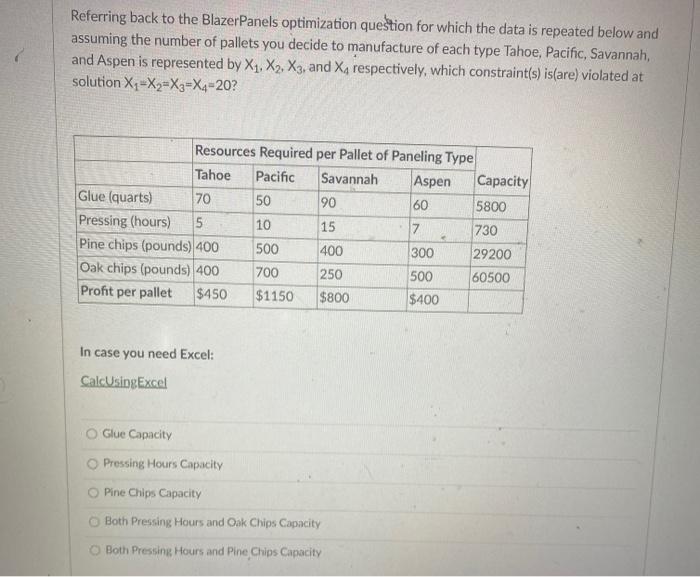

Blazer Panels produces four different types of wood paneling. Each type of paneling is made by gluing and pressing together a different mixture of pine and oak chips. The following table summarizes the required amount of gluing, presing, and mixture of wood chips required to produce a single pallet of each type of paneling: 70 Resources Required per Pallet of Paneling Type Tahoe Pacific Savannah Aspen Glue (quarts) 50 90 60 Pressing (hours) 5 10 15 7. Pine chips (pounds) 400 500 400 300 Oak chips (pounds) 400 700 250 500 In the next production cycle, you have 5,800 quarts of glue; 730 hours of pressing capacity: 29,200 pounds of pine chips; and 60,500 pounds of oak chips available. Further assume that each pallet of Tahoe, Pacific, Savannah, and Aspen panels can be sold for profits of $450, $1,150, $800, and $400, respectively. Assuming the number of pallets you decide to manufacture of each type Tahoe, Pacific, Savannah, and Aspen is represented by X1, X2, X3, and X, respectively, which of the following is NOT correct for a solution where X1-X7-Xy-X-1? In case you need Excel: CalcUsingExcel The objective function value will be $2800 50 90 60 10 Glue (quarts) 70 Pressing (hours) 5 Pine chips (pounds) 400 Oak chips (pounds) 400 15 7 500 400 300 500 700 250 In the next production cycle, you have 5,800 quarts of glue; 730 hours of pressing capacity: 29,200 pounds of pine chips; and 60,500 pounds of oak chips available. Further assume that each pallet of Tahoe, Pacific, Savannah, and Aspen panels can be sold for profits of $450, $1,150, $800, and $400, respectively. Assuming the number of pallets you decide to manufacture of each type Tahoe, Pacific, Savannah, and Aspen is represented by X1, X3, X3, and X4 respectively, which of the following is NOT correct for a solution where X2=Xy=X3=X4=1? In case you need Excel: CalcUsingExcel The objective function value will be $2800 There will be 650 hours of pressing hours left There will be 5530 quarts of glue left There will be 27600 pounds of pine chips left There will be 58650 pounds of oak chips left Referring back to the Blazer Panels optimization question for which the data is repeated below and assuming the number of pallets you decide to manufacture of each type Tahoe, Pacific, Savannah, and Aspen is represented by X1, X2, X3, and X4 respectively, what is the constraint on pressing hours? Resources Required per Pallet of Paneling Type Tahoe Pacific Savannah Aspen Capacity Glue (quarts) 70 50 90 60 5800 Pressing (hours) 5 10 15 7 730 Pine chips (pounds) 400 500 400 300 29200 Oak chips (pounds) 400 700 250 500 60500 Profit per pallet $450 $1150 $800 $400 In case you need Excel: CalcUsingExcel O 70X, +50X2 + 90X2 + 60X, 5800 70X1 +50X2 + 90X3 + 60X4 >= 580 O 5X, + 10X+ 15%, +7X4 - 730 O 5X1 + 10%, 15%+7X4