Question: Milling is a unit operation to control the particle size by transforming solid particles into smaller ones by applying forces such as shear, compression, friction,

Milling is a unit operation to control the particle size by transforming solid particles into smaller ones by applying forces such as shear, compression, friction, collision, or impact. The bead mill is an apparatus that agitates the beads in a cylindrical vessel to disperse minute particles in a slurry. The motion of the bead induces shear and impact on the particles. One of the major factors affecting the particle size is the size and material of bead chosen for milling. It affects the frequency of impact between the bead and the final particle size to be achieved. Fine drug particles are especially desired in formulations designed for parenteral, respiratory and transdermal use. For the detail provided below:

In this case study, contestants are tasked with optimizing the milling operation, particularly selecting the material of bead, duration of operation and shaft kinetics.

Additionally, they need to address challenges related to process scalability, transfer limitations, formulation considerations, product stability and contamination risks control. Moreover, researching literature for valuable insights and potential solutions will be critical to devising an efficient and effective milling process.

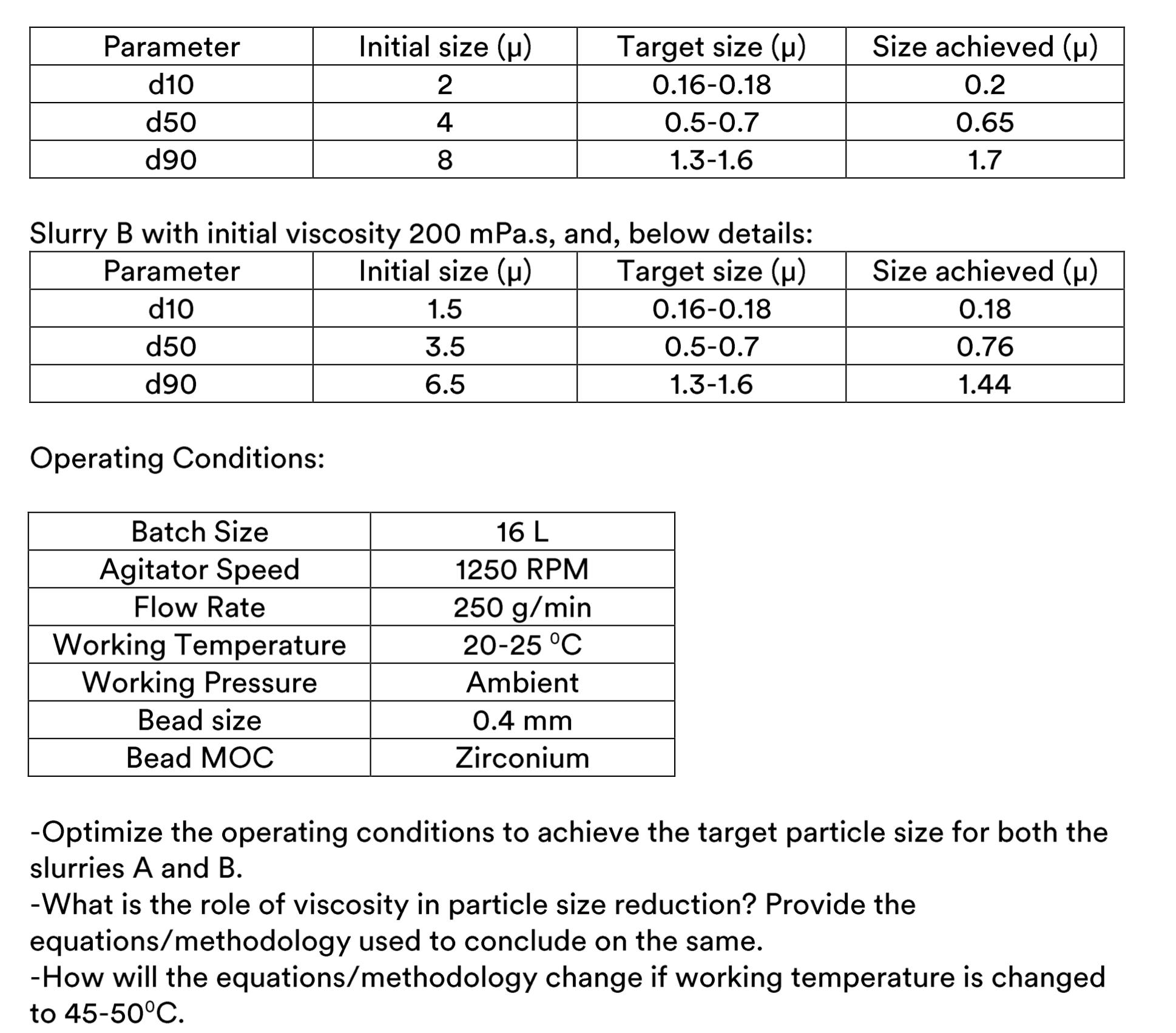

Slurry A with initial viscosity 5mPa.s, and, below details:

Parameter d10 d50 d90 Operating Conditions: Slurry B with initial viscosity 200 mPa.s, and, below details: Parameter Initial size () Target size () d10 1.5 0.16-0.18 d50 3.5 0.5-0.7 d90 6.5 1.3-1.6 Batch Size Agitator Speed Flow Rate Working Temperature Working Pressure Initial size (u) 2 4 8 Bead size Bead MOC 16 L 1250 RPM 250 g/min 20-25 C Ambient Target size (u) 0.16-0.18 0.5-0.7 1.3-1.6 0.4 mm Zirconium Size achieved () 0.2 0.65 1.7 Size achieved () 0.18 0.76 1.44 -Optimize the operating conditions to achieve the target particle size for both the slurries A and B. -What is the role of viscosity in particle size reduction? Provide the equations/methodology used to conclude on the same. -How will the equations/methodology change if working temperature is changed to 45-50C.

Step by Step Solution

3.41 Rating (164 Votes )

There are 3 Steps involved in it

1 To optimize the operating conditions and achieve the target particle size for both slurries A and B you can follow these steps Start by selecting th... View full answer

Get step-by-step solutions from verified subject matter experts