Question: Mr Justin, the Centre Manager, has received comments from other departments recently that WRC is inefficient in processing the warranty returns. Furthermore, the return volume

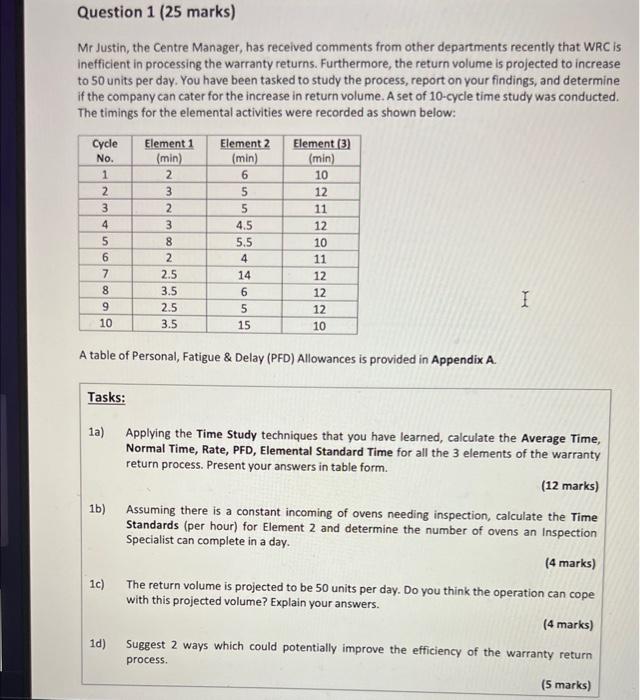

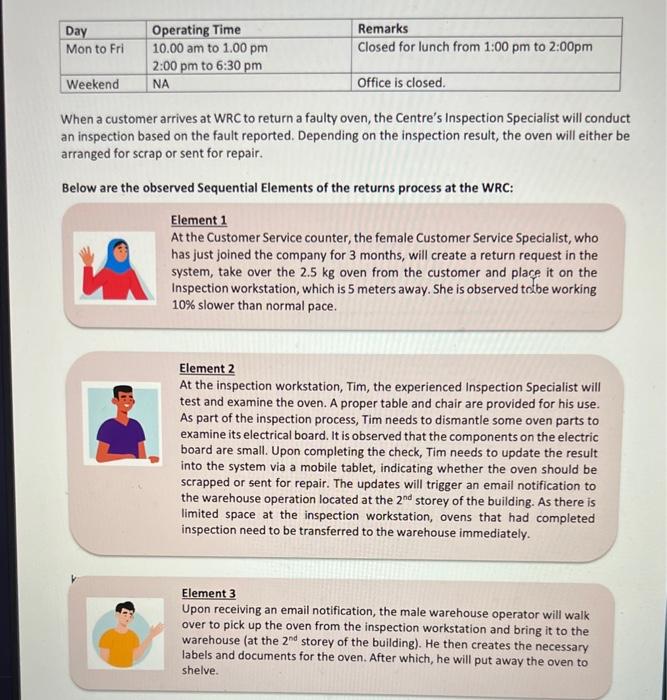

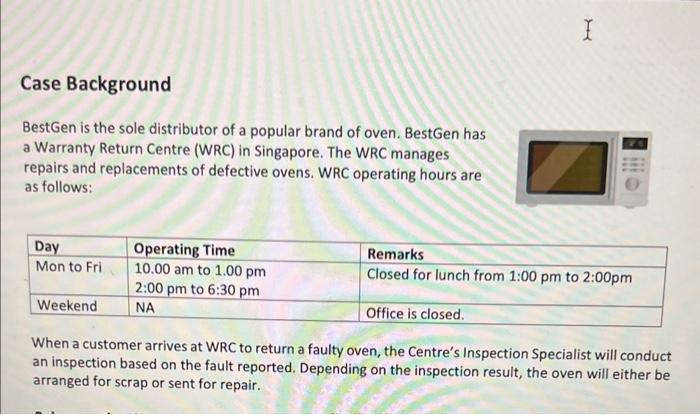

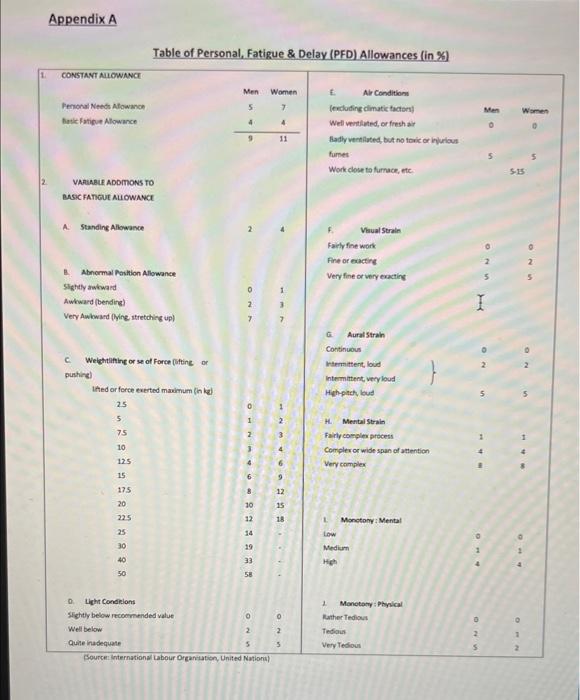

Mr Justin, the Centre Manager, has received comments from other departments recently that WRC is inefficient in processing the warranty returns. Furthermore, the return volume is projected to increase to 50 units per day. You have been tasked to study the process, report on your findings, and determine if the company can cater for the increase in return volume. A set of 10-cycle time study was conducted. The timings for the elemental activities were recorded as shown below: A table of Personal, Fatigue \& Delay (PFD) Allowances is provided in Appendix A. Tasks: 1a) Applying the Time Study techniques that you have learned, calculate the Average Time, Normal Time, Rate, PFD, Elemental Standard Time for all the 3 elements of the warranty return process. Present your answers in table form. (12 marks) 1b) Assuming there is a constant incoming of ovens needing inspection, calculate the Time Standards (per hour) for Element 2 and determine the number of ovens an Inspection Specialist can complete in a day. (4 marks) 1c) The return volume is projected to be 50 units per day. Do you think the operation can cope with this projected volume? Explain your answers. (4 marks) 1d) Suggest 2 ways which could potentially improve the efficiency of the warranty return process. (5 marks) When a customer arrives at WRC to return a faulty oven, the Centre's Inspection Specialist will conduct an inspection based on the fault reported. Depending on the inspection result, the oven will either be arranged for scrap or sent for repair. Below are the observed Sequential Elements of the returns process at the WRC: Element 1 At the Customer Service counter, the female Customer Service Specialist, who has just joined the company for 3 months, will create a return request in the system, take over the 2.5kg oven from the customer and place it on the Inspection workstation, which is 5 meters away. She is observed tribe working 10% slower than normal pace. Element 2 At the inspection workstation, Tim, the experienced Inspection Specialist will test and examine the oven. A proper table and chair are provided for his use. As part of the inspection process, Tim needs to dismantle some oven parts to examine its electrical board. It is observed that the components on the electric board are small. Upon completing the check, Tim needs to update the result into the system via a mobile tablet, indicating whether the oven should be scrapped or sent for repair. The updates will trigger an email notification to the warehouse operation located at the 2nd storey of the building. As there is limited space at the inspection workstation, ovens that had completed inspection need to be transferred to the warehouse immediately. Element 3 Upon receiving an email notification, the male warehouse operator will walk over to pick up the oven from the inspection workstation and bring it to the warehouse (at the 2nd storey of the building). He then creates the necessary labels and documents for the oven. After which, he will put away the oven to shelve. Case Background BestGen is the sole distributor of a popular brand of oven. BestGen has a Warranty Return Centre (WRC) in Singapore. The WRC manages repairs and replacements of defective ovens. WRC operating hours are as follows: When a customer arrives at WRC to return a faulty oven, the Centre's Inspection Specialist will conduct an inspection based on the fault reported. Depending on the inspection result, the oven will either be arranged for scrap or sent for repair. Appendix A Table of Personal, Fatigue \& Delay (PFD) Allowances (in \%)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts