Question: My work below I need help check problem 4 and 5 Case 3 -- Line Balancing Quality Technology (QT), Inc. was founded by two first-year

My work below

I need help check problem 4 and 5

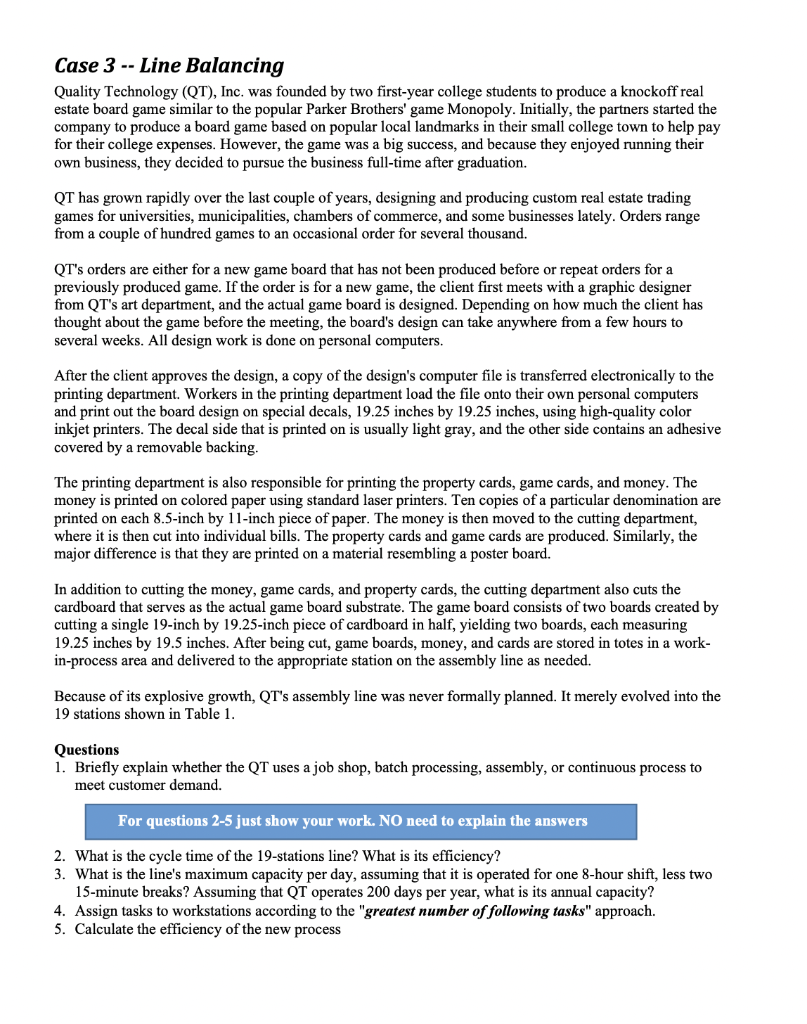

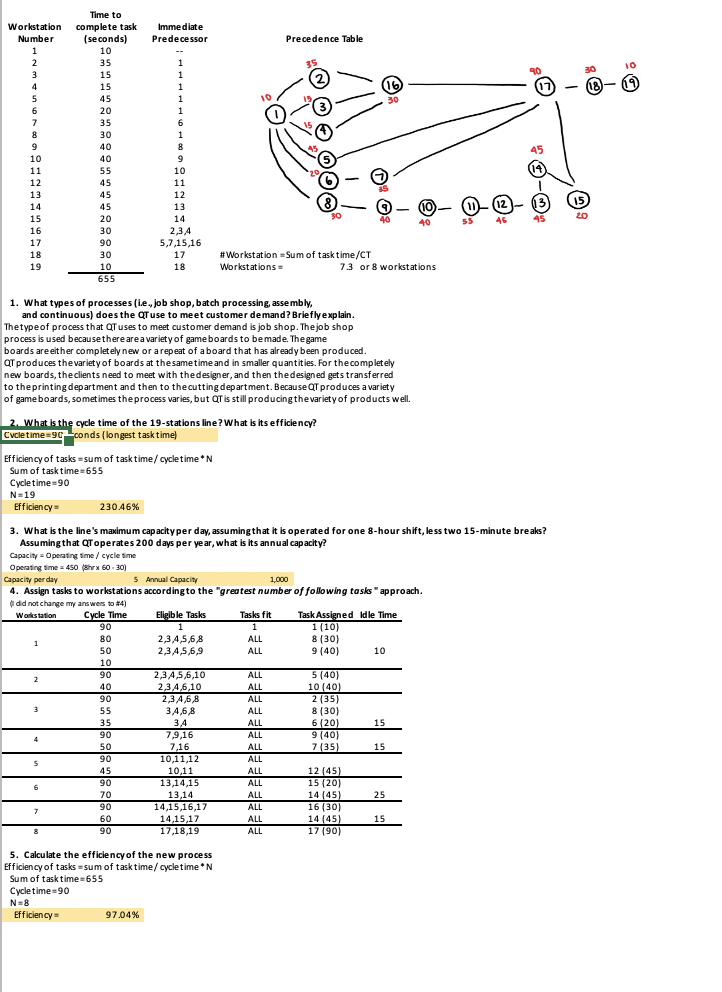

Case 3 -- Line Balancing Quality Technology (QT), Inc. was founded by two first-year college students to produce a knockoff real estate board game similar to the popular Parker Brothers' game Monopoly. Initially, the partners started the company to produce a board game based on popular local landmarks in their small college town to help pay for their college expenses. However, the game was a big success, and because they enjoyed running their own business, they decided to pursue the business full-time after graduation. QT has grown rapidly over the last couple of years, designing and producing custom real estate trading games for universities, municipalities, chambers of commerce, and some businesses lately. Orders range from a couple of hundred games to an occasional order for several thousand. QT's orders are either for a new game board that has not been produced before or repeat orders for a previously produced game. If the order is for a new game, the client first meets with a graphic designer from QT's art department, and the actual game board is designed. Depending on how much the client has thought about the game before the meeting, the board's design can take anywhere from a few hours to several weeks. All design work is done on personal computers. After the client approves the design, a copy of the design's computer file is transferred electronically to the printing department. Workers in the printing department load the file onto their own personal computers and print out the board design on special decals, 19.25 inches by 19.25 inches, using high-quality color inkjet printers. The decal side that is printed on is usually light gray, and the other side contains an adhesive covered by a removable backing. The printing department is also responsible for printing the property cards, game cards, and money. The money is printed on colored paper using standard laser printers. Ten copies of a particular denomination are printed on each 8.5-inch by 11-inch piece of paper. The money is then moved to the cutting department, where it is then cut into individual bills. The property cards and game cards are produced. Similarly, the major difference is that they are printed on a material resembling a poster board. In addition to cutting the money, game cards, and property cards, the cutting department also cuts the cardboard that serves as the actual game board substrate. The game board consists of two boards created by cutting a single 19-inch by 19.25-inch piece of cardboard in half, yielding two boards, each measuring 19.25 inches by 19.5 inches. After being cut, game boards, money, and cards are stored in totes in a work- in-process area and delivered to the appropriate station on the assembly line as needed. Because of its explosive growth, QT's assembly line was never formally planned. It merely evolved into the 19 stations shown in Table 1. Questions 1. Briefly explain whether the QT uses a job shop, batch processing, assembly, or continuous process to meet customer demand. For questions 2-5 just show your work. NO need to explain the answers 2. What is the cycle time of the 19-stations line? What is its efficiency? 3. What the line's maximum capacity per day, assuming that it is operated for one 8-hour shift, less two 15-minute breaks? Assuming that QT operates 200 days per year, what is its annual capacity? 4. Assign tasks to workstations according to the "greatest number of following tasks" approach. 5. Calculate the efficiency of the new process Immediate Predecessor 1 1 1 1 1 6 1 8 9 Table 1 Time to Workstation Task(s) Performed at Station Perform Number Tasks 1 Get box bottom and place plastic money tray in box bottom. Take 10 seconds two dice bin and place in box bottom in area not take up by tray. 2 Count out 35 plastic houses and place in box bottom. 35 seconds 3 Count out 15 plastic hotels and place in box bottom. 15 seconds 4 Take one game piece from each of eight bins and place them in 15 seconds box bottom 5 Take one property card from each of 28 bins. Place rubber band 45 seconds around property cards and place cards in box bottom. 6 Take one orange card from each of 15 bins. Place rubber band 20 seconds around cards and place cards in box bottom. 7 Take one yellow card from each of 15 bins. Take orange cards 35 seconds from box and remove rubber band. Place yellow cards on top of orange cards. Place rubber band around yellow and orange cards and place cards in box bottom. 8 Count out 25 $500 bills and attach to cardboard strip with rubber 30 seconds band. Place money in box bottom. 9 Count out 20 $100 bills. Take $500 bills from box bottom and 40 seconds remove rubber band. Place $100 bills on top of $500 bills. Attach rubber band around money and place in box bottom. 10 Count out 25 $50 bills. Take $500 and $100 bills from box bottom 40 seconds and remove rubber band. Place $50 bills on top. Attach rubber band around money and place in bottom box. 11 Count out 50 $20 bills. Take money in box and remove rubber band. 55 seconds Place $20 bills on top. Attach rubber band around money and place in box bottom. 12 Count at 40 $10 bills. Take money in box and remove rubber band. 45 seconds Place $10 bills on top. Attach rubber band around money and place in box bottom. 13 Count out 40 $5 bills. Take money in box and remove rubber band. 45 seconds Place $5 bills on top. Attach rubber band around money and place in box bottom. 14 Count at 40 $1 bills. Take money in box and remove rubber band. 45 seconds Place $1 bills on top. Attach rubber band around money and place in box bottom. 15 Take money and remove rubber band. Shrink wrap money and place 20 seconds in box bottom. 16 Take houses, hotels, dice, and game pieces and place in big. Seal 30 seconds bag and place bag in box. 17 Place two cardboard game board halves in fixture so that they are 90 seconds separated by 4 in. Peel backing off of printed game board decal. Align decal over board halves and lower it down. Remove board from fixture and flip it over. Attach solid blue backing decal. Flip game board over again and fold blue backing over front of game board, creating a / in, border. Fold game board in half and place in box covering money tray, game pieces, and cards. 18 Place game instructions in box. Place box top on box bottom. Shrink 30 seconds wrap entire box. 19 Place completed box in carton. 10 seconds 10 11 12 13 14 2,3,4 5,7,15,16 17 18 Immediate Predecessor Precedence Table 90 19 10 16 30 ( Workstation Number 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 Time to complete task (seconds) 10 35 15 15 45 20 35 30 40 40 55 45 45 45 20 30 90 30 10 655 45 1 1 1 1 1 1 6 6 1 8 9 10 11 12 13 14 2,34 5,7,15,16 17 18 15 3) 45 20 40 40 55 46 #Workstation Sum of task time/CT Workstations 7.3 or 8 workstations 1. What types of processes (le, job shop, batch processing, assembly, , and continuous) does the QT use to meet customer demand? Briefly explain. The type of process that QT uses to meet customer demand is job shop. The job shop process is used because there are a variety of game boards to be made. The game boards are either completely new or arepeat of aboard that has already been produced ar produces the variety of boards at the same time and in smaller quantities. For the completely new boards, the clients need to meet with thedesigner, and then the designed gets transferred to the printing department and then to the cutting department. Because QT produces a variety of gameboards, sometimes the process varies, but QT is still producing the variety of products well. 2. What is the cycle time of the 19-stations line? What is its efficiency? Cycle time=90-conds (longest task time) Efficiency of tasks sum of task time / cycle time Sum of task time=655 Cycle time=90 N=19 Efficiency 230.46% ALL 3. What is the line's maximum capacity per day, assuming that it is operated for one 8-hour shift, less two 15-minute breaks? Assuming that OT operates 200 days per year, what is its annual capacity? Capacity - Operating time / cycle time Operating time = 450 (shrx 60-30) Capacity per day 5 Annual Capacity 1,000 4. Assign tasks to workstations according to the greatest number of following tasks" approach. I did not change my answers to 14) Workstation Cycle Time Eligible Tasks Tasks fit Task Assigned Idle Time 90 1 1 1 (10) 80 1 2,3,4,5,6,8 ALL 8 (30) 50 2,3,4,5,6,9 9 (40) 10 10 2 90 2,3,4,5,6,10 ALL 5 (40) 40 2,3,4,6,10 ALL 10 (40) 90 2,3,4,6,8 ALL 2 (35) 2 3 55 3,4,6,8 ALL 8 (30) 35 3,4 ALL 6 (20) 15 90 7,9,16 ALL 9 (40) 50 7,16 ALL 7 (35) 15 90 10,11,12 ALL 45 10,11 ALL 12 (45) 90 13,14,15 ALL 15 (20) 70 13,14 ALL 14 (45) 25 90 7 14,15,16,17 ALL 16 (30) 60 14,15,17 ALL 14 (45) 15 90 17,18,19 ALL 17 (90) 4 5 5. Calculate the efficiency of the new process Efficiency of tasks asum of task time / cycle time.N Sum of task time=655 Cycle time=90 N=8 Efficiency 97.04%Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock