Question: Need help with this management science problem! QUESTION 1 Frandec Company manufactures, assembles, and rebuilds material handling equipment used in warehouses and distribution centers. One

Need help with this management science problem!

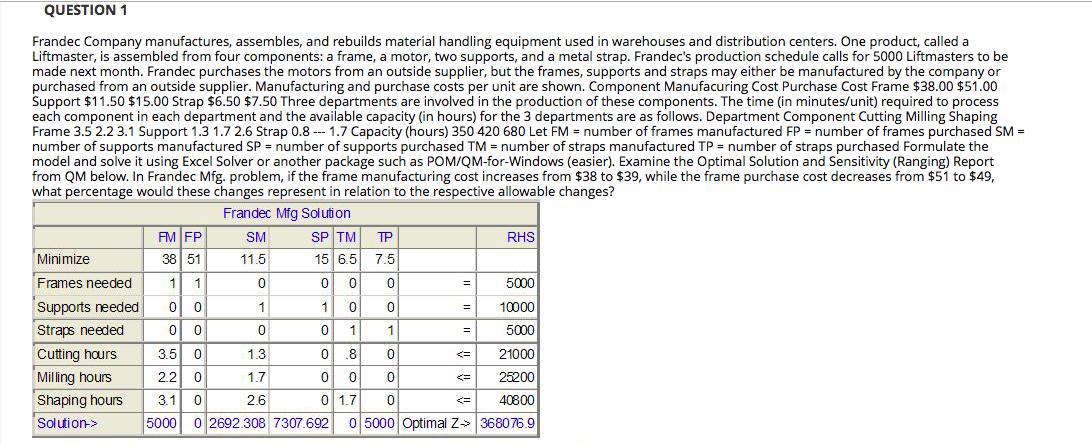

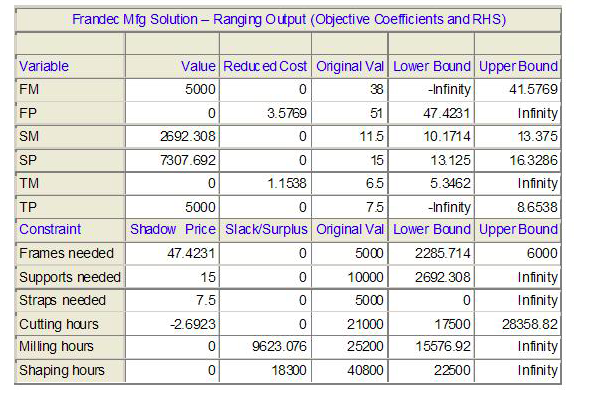

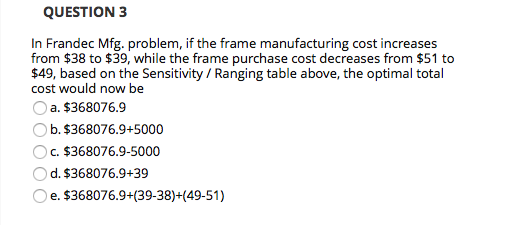

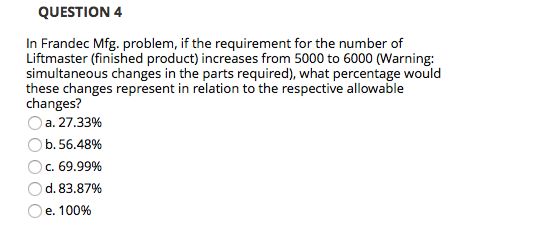

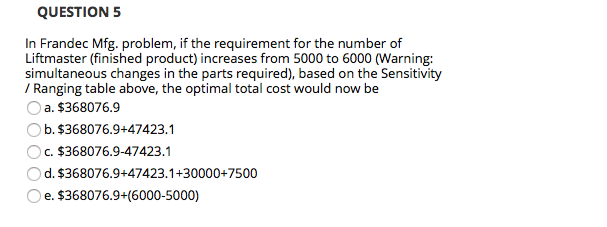

QUESTION 1 Frandec Company manufactures, assembles, and rebuilds material handling equipment used in warehouses and distribution centers. One product, called a Liftmaster, is assembled from four components: a frame, a motor, two supports, and a metal strap. Frandec's production schedule calls for 5000 Liftmasters to be made next month. Frandec purchases the motors from an outside supplier, but the frames, supports and straps may either be manufactured by the company or purchased from an outside supplier. Manufacturing and purchase costs per unit are shown. Component Manufacuring Cost Purchase Cost Frame $38.00 $51.00 Support $11.50 $15.00 Strap $6.50 $7.50 Three departments are involved in the production of these components. The time (in minutes/unit) required to process each component in each department and the available capacity (in hours) for the 3 departments are as follows. Department Component Cutting Milling Shaping Frame 3.5 2.2 3.1 Support 1.3 1.7 2.6 Strap 0.8 --- 1.7 Capacity (hours) 350 420 680 Let FM = number of frames manufactured FP = number of frames purchased SM = number of supports manufactured SP = number of supports purchased TM = number of straps manufactured TP = number of straps purchased Formulate the model and solve it using Excel Solver or another package such as POM/QM-for-Windows (easier). Examine the optimal Solution and Sensitivity (Ranging) Report from QM below. In Frandec Mfg. problem, if the frame manufacturing cost increases from $38 to $39, while the frame purchase cost decreases from $51 to $49, what percentage would these changes represent in relation to the respective allowable changes? Frandec Mfg Solution AMFP SM SP TM TP RHS Minimize 38 51 11.5 15 6.5 7.5 Frames needed 1 1 0 0 0 0 5000 Supports needed 0 0 1 1 0 0 10000 Straps needed 0 0 0 0 1 1 = 5000 Cutting hours 35 0 1. 3 0. 80 21000 Milling hours 22 0 1.7 0 0 0 25200 Shaping hours 3.1 0 6 2. 0 1. 7 0 40800 Solution-> 5000 02692.308 7307.692 0 5000 Optimal Z> 368076.9 II III Frandec Mfg Solution - Ranging Output (Objective Coefficients and RHS) Variable FM FP SM SP TM Constraint Frames needed Supports needed Straps needed Cutting hours Milling hours Shaping hours Value Reduced Cost Original Val Lower Bound Upper Bound 5000 0 3 8 -Infinity 41.5769 0 3 .5769 51 47.4231 Infinity 2692.308 115 10.1714 13.375 7307.692 0 1513125 16 3286 0 1.1538 65 5.3462 Infinity 5000 75 Infinity 86538 Shadow Price Slack/Surplus Original ValLower Bound Upper Bound 47.4231 5000 2285.714 6000 15 10000 2692 308 Infinity 7.5 0 5000 Infinity -2.6923 o 21000 17500 28358.82 0 9 623.076 25200 15576.92 Infinity 0 1 8300 40800 22500 Infinity QUESTION 3 In Frandec Mfg. problem, if the frame manufacturing cost increases from $38 to $39, while the frame purchase cost decreases from $51 to $49, based on the Sensitivity / Ranging table above, the optimal total cost would now be a. $368076.9 b. $368076.9+5000 c. $368076.9-5000 d. $368076.9+39 e. $368076.9+(39-38)+(49-51) QUESTION 4 In Frandec Mfg, problem, if the requirement for the number of Liftmaster (finished product) increases from 5000 to 6000 (Warning: simultaneous changes in the parts required), what percentage would these changes represent in relation to the respective allowable changes? O a. 27.33% Ob.56.48% c. 69.99% O d. 83.87% e. 100% QUESTION 5 In Frandec Mfg. problem, if the requirement for the number of Liftmaster (finished product) increases from 5000 to 6000 (Warning: simultaneous changes in the parts required), based on the Sensitivity / Ranging table above, the optimal total cost would now be O a. $368076.9 Ob. $368076.9+47423.1 Oc. $368076.9-47423.1 d. $368076.9+47423.1+30000+7500 e. $368076.9+(6000-5000) QUESTION 1 Frandec Company manufactures, assembles, and rebuilds material handling equipment used in warehouses and distribution centers. One product, called a Liftmaster, is assembled from four components: a frame, a motor, two supports, and a metal strap. Frandec's production schedule calls for 5000 Liftmasters to be made next month. Frandec purchases the motors from an outside supplier, but the frames, supports and straps may either be manufactured by the company or purchased from an outside supplier. Manufacturing and purchase costs per unit are shown. Component Manufacuring Cost Purchase Cost Frame $38.00 $51.00 Support $11.50 $15.00 Strap $6.50 $7.50 Three departments are involved in the production of these components. The time (in minutes/unit) required to process each component in each department and the available capacity (in hours) for the 3 departments are as follows. Department Component Cutting Milling Shaping Frame 3.5 2.2 3.1 Support 1.3 1.7 2.6 Strap 0.8 --- 1.7 Capacity (hours) 350 420 680 Let FM = number of frames manufactured FP = number of frames purchased SM = number of supports manufactured SP = number of supports purchased TM = number of straps manufactured TP = number of straps purchased Formulate the model and solve it using Excel Solver or another package such as POM/QM-for-Windows (easier). Examine the optimal Solution and Sensitivity (Ranging) Report from QM below. In Frandec Mfg. problem, if the frame manufacturing cost increases from $38 to $39, while the frame purchase cost decreases from $51 to $49, what percentage would these changes represent in relation to the respective allowable changes? Frandec Mfg Solution AMFP SM SP TM TP RHS Minimize 38 51 11.5 15 6.5 7.5 Frames needed 1 1 0 0 0 0 5000 Supports needed 0 0 1 1 0 0 10000 Straps needed 0 0 0 0 1 1 = 5000 Cutting hours 35 0 1. 3 0. 80 21000 Milling hours 22 0 1.7 0 0 0 25200 Shaping hours 3.1 0 6 2. 0 1. 7 0 40800 Solution-> 5000 02692.308 7307.692 0 5000 Optimal Z> 368076.9 II III Frandec Mfg Solution - Ranging Output (Objective Coefficients and RHS) Variable FM FP SM SP TM Constraint Frames needed Supports needed Straps needed Cutting hours Milling hours Shaping hours Value Reduced Cost Original Val Lower Bound Upper Bound 5000 0 3 8 -Infinity 41.5769 0 3 .5769 51 47.4231 Infinity 2692.308 115 10.1714 13.375 7307.692 0 1513125 16 3286 0 1.1538 65 5.3462 Infinity 5000 75 Infinity 86538 Shadow Price Slack/Surplus Original ValLower Bound Upper Bound 47.4231 5000 2285.714 6000 15 10000 2692 308 Infinity 7.5 0 5000 Infinity -2.6923 o 21000 17500 28358.82 0 9 623.076 25200 15576.92 Infinity 0 1 8300 40800 22500 Infinity QUESTION 3 In Frandec Mfg. problem, if the frame manufacturing cost increases from $38 to $39, while the frame purchase cost decreases from $51 to $49, based on the Sensitivity / Ranging table above, the optimal total cost would now be a. $368076.9 b. $368076.9+5000 c. $368076.9-5000 d. $368076.9+39 e. $368076.9+(39-38)+(49-51) QUESTION 4 In Frandec Mfg, problem, if the requirement for the number of Liftmaster (finished product) increases from 5000 to 6000 (Warning: simultaneous changes in the parts required), what percentage would these changes represent in relation to the respective allowable changes? O a. 27.33% Ob.56.48% c. 69.99% O d. 83.87% e. 100% QUESTION 5 In Frandec Mfg. problem, if the requirement for the number of Liftmaster (finished product) increases from 5000 to 6000 (Warning: simultaneous changes in the parts required), based on the Sensitivity / Ranging table above, the optimal total cost would now be O a. $368076.9 Ob. $368076.9+47423.1 Oc. $368076.9-47423.1 d. $368076.9+47423.1+30000+7500 e. $368076.9+(6000-5000)Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock