Question: Need Recommendations for this case. At lease three paragraphs. please help! Jim learned that the gatherer chain was purchased from Saunders Manufacturing (Saunders), a supplier

Need Recommendations for this case. At lease three paragraphs. please help!

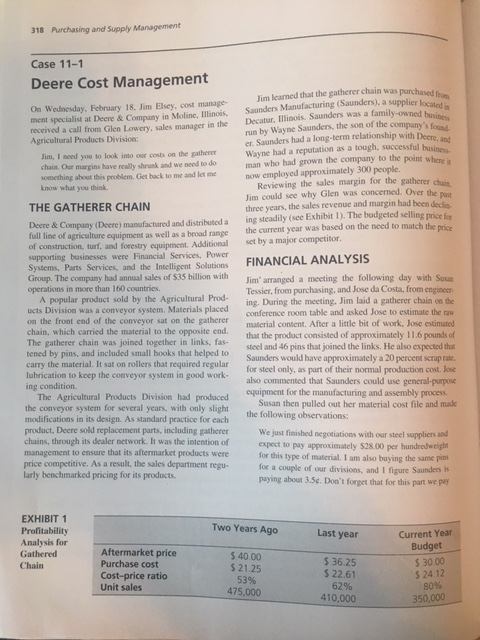

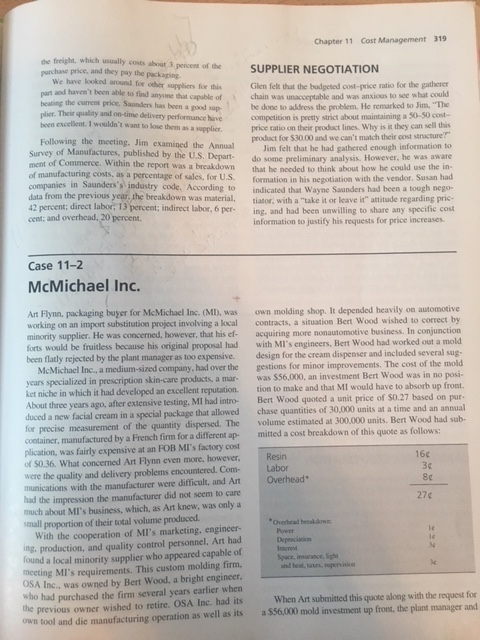

Jim learned that the gatherer chain was purchased from Saunders Manufacturing (Saunders), a supplier located in Decatur, Illinois, Saunders was a family-owned business run by Wayne Saunders, the son of the company's found er Saunders had a long-term relationship with Deere, and Wayne had a reputation as a tough, successful business 318 Purchasing and Supply Management Case 11-1 Deere Cost Management On Wednesday, February 18, Jim Elsey, cost manage- ment specialist at Deere & Company in Moline, Illinois, received a call from Glen Lowery, sales manager in the Agricultural Products Division: Jim, I need you to look into our costs on the gatherer chain. Our margins have really shrunk and we need to do something about this problem. Get back to me and let me know what you think THE GATHERER CHAIN Deere & Company (Deere) manufactured and distributed a full line of agriculture equipment as well as a broad range of construction, turf, and forestry equipment. Additional supporting businesses were Financial Services, Power Systems, Parts Services, and the Intelligent Solutions Group. The company had annual sales of $35 billion with operations in more than 160 countries A popular product sold by the Agricultural Prod. ucts Division was a conveyor system. Materials placed on the front end of the conveyor sat on the gatherer chain, which carried the material to the opposite end. The gatherer chain was joined together in links, fas- tened by pins, and included small hooks that helped to carry the material. It sat on rollers that required regular lubrication to keep the conveyor system in good work- ing condition. The Agricultural Products Division had produced the conveyor system for several years, with only slight modifications in its design. As standard practice for each product, Deere sold replacement parts, including gatherer chains, through its dealer network. It was the intention of management to ensure that its aftermarket products were price competitive. As a result, the sales department regu- larly benchmarked pricing for its products. man who had grown the company to the point where is now employed approximately 300 people. Reviewing the sales margin for the gatherer chain Jim could see why Glen was concerned. Over the past three years, the sales revenue and margin had been declis ing steadily (see Exhibit 1). The budgeted selling price for the current year was based on the need to match the price set by a major competitor. FINANCIAL ANALYSIS Jim' arranged a meeting the following day with Susan Tessier, from purchasing, and Jose da Costa, from engineer ing. During the meeting. Jim laid a gatherer chain on the conference room table and asked Jose to estimate the row material content. After a little bit of work, Jose estimated that the product consisted of approximately 11.6 pounds of stoel and 46 pins that joined the links. He also expected that Saunders would have approximately a 20 percent scrap rate. for steel only, as part of their normal production cost. Jose also commented that Saunders could use general-purpose equipment for the manufacturing and assembly process Susan then pulled out her material cost file and made the following observations: We just finished negotiations with our steel suppliers and expect to pay approximately $28.00 per hundredweight for this type of material. I am also buying the same pits for a couple of our divisions, and I figure Saunders is paying about 3.5e. Don't forget that for this part we pay Two Years Ago Last year EXHIBIT 1 Profitability Analysis for Gathered Chain Aftermarket price Purchase cost Cost-price ratio Unit sales $ 40.00 $21.25 53% 475,000 $36.25 $ 22.61 62% 410.000 Current Year Budget $ 30.00 $ 24.12 80% 350.000 Chapter 11 Cost Management 319 freight which usually costs about 3 percent of the purchase price, and they pay the packaging We have booked around for other suppliers for this part and haven't been able to find anyone that capable of beating the current price. Saunders has been a good up plier. Their quality and on-time delivery performance live bers excellent. I wouldn't want to lose them as applier. Following the meeting. Jim examined the Annual Survey of Manufactures, published by the U.S. Depart- ment of Commerce. Within the report was a breakdown of manufacturing costs, as a percentage of sales, for U.S. companies in Saunders's industry code. According to data from the previous year, the breakdown was material, 42 percent direct labor: 13 percent; indirect labor, 6 per- cent: and overhead, 20 percent. SUPPLIER NEGOTIATION Glen felt that the budgeted cost-price ratio for the gatherer chain was unacceptable and was anxious to see what could be done to address the problem. He remarked to Jim, "The competition is pretty strict about maintaining a 50-50 cost price ratio on their product lines. Why is it they can sell this product for $30.00 and we can't match their cost structure?" Jim felt that he had gathered enough information to do some preliminary analysis. However, he was aware that he needed to think about how he could use the in- formation in his negotiation with the vendor. Susan had indicated that Wayne Saunders had been a tough nego tiator, with a "take it or leave it" attitude regarding pric- ing, and had been unwilling to share any specific cost information to justify his requests for price increases. Case 11-2 McMichael Inc. own molding shop. It depended heavily on automotive contracts, a situation Bert Wood wished to correct by acquiring more nonautomotive business. In conjunction with MI's engineers, Bert Wood had worked out a mold design for the cream dispenser and included several sug. gestions for minor improvements. The cost of the mold was $56,000, an investment Bert Wood was in no posi- tion to make and that MI would have to absorb up front. Bert Wood quoted a unit price of $0.27 based on pur chase quantities of 30,000 units at a time and an annual volume estimated at 300,000 units. Bert Wood had sub- mitted a cost breakdown of this quote as follows: Art Flynn, packaging buyer for McMichael Inc. (MI), was working on an import substitution project involving a local minority supplier. He was concerned, however, that his ef- forts would be fruitless because his original proposal had been flatly rejected by the plant manager as too expensive. McMichael Inc., a medium-sized company, had over the years specialized in prescription skin care products, a mar- ket niche in which it had developed an excellent reputation. About three years ago, after extensive testing, MI had intro- duced a new facial cream in a special package that allowed for precise measurement of the quantity dispersed. The container, manufactured by a French firm for a different ap- plication was fairly expensive at an FOB MI's factory cost of $0.36. What concerned Art Flynn even more, however, were the quality and delivery problems encountered. Com. munications with the manufacturer were difficult, and Art had the impression the manufacturer did not seem to care much about MI's business, which, as Art knew, was only a small proportion of their total volume produced With the cooperation of Mi's marketing, engineer ing, production, and quality control personnel, Art had found a local minority supplier who appeared capable of meeting MI's requirements. This custom molding firm, OSA Inc., was owned by Bert Wood, a bright engineer. who had purchased the firm several years earlier when the previous owner wished to retire. OSA Inc. had its own tool and die manufacturing operation as well as its Resin Labor Overhead 166 36 8C 276 1 3 When Art submitted this quote along with the request for a $56.000 mold investment up front, the plant manager andStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts