Question: NEEDED ANSWER FOR QUESTION NO- 2 2. What are the problems with the current manufacturing process as a whole and with the adhesive coating machine

NEEDED ANSWER FOR QUESTION NO- 2

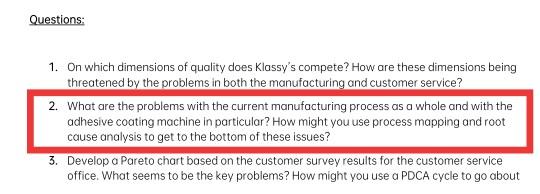

2. What are the problems with the current manufacturing process as a whole and with the adhesive coating machine in particular? How might you use process mapping and root cause analysis to get to the bottom of these issues?

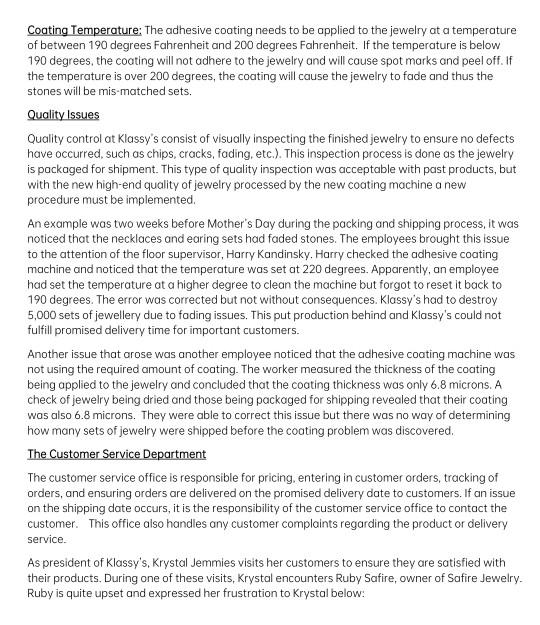

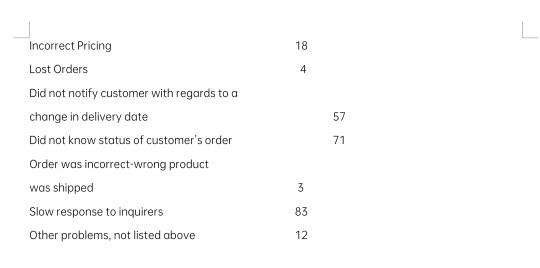

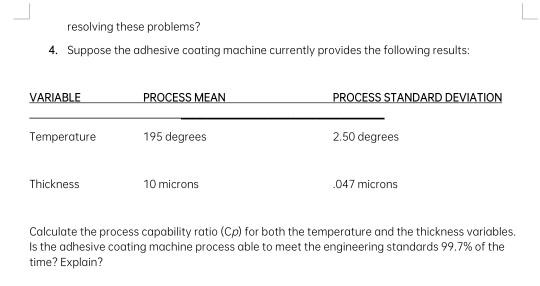

IBM 1000: CASE STUDY 3: KLASSY ROYAL FAMILY JEWELRY Introduction Krystal Jemmies, President of marketing at Klassy Royal Family Jewelry, is overwhelmed with the success of her new line of Gemstone-Royal jewelry. This line of costume Jewelry is different from other regular jewelry. Gemstone Royal jewelry consists of crafted "jems" that have a special coating on the surface that makes them resistant to chipping and fading. The jewelry is durable and easy to maintain Manufacturing of the new line of jewelry requires Klassy to lease a special machine to apply the adhesive coating to the jem stones and has put a special drying process in place for the jewelry to "cure" properly. Klassy's research and development (R&D) lab has determined that in order to produce the high-end jewelry without defects, the machine must apply the coating to the stones at a proper temperature and thickness. R&D has given the following guidelines for the jewelry: Coating Thickness: The optimal coating thickness is 10 microns. If the coating is greater than 11 microns, the jewelry will take too long to dry. If the coating is less than 9 microns, the stones will be subject to damage and break easily (become brittle). Coating Temperature: The adhesive coating needs to be applied to the jewelry at a temperature of between 190 degrees Fahrenheit and 200 degrees Fahrenheit. If the temperature is below 190 degrees, the coating will not adhere to the jewelry and will cause spot marks and peel off. If the temperature is over 200 degrees, the coating will cause the jewelry to fade and thus the stones will be mis-matched sets, Quality Issues Quality control at Klassy's consist of visually inspecting the finished jewelry to ensure no defects have occurred, such as chips, cracks, fading, etc.). This inspection process is done as the jewelry is packaged for shipment. This type of quality inspection was acceptable with past products, but with the new high-end quality of jewelry processed by the new coating machine a new procedure must be implemented. An example was two weeks before Mother's Day during the packing and shipping process, it was noticed that the necklaces and earing sets had faded stones. The employees brought this issue to the attention of the floor supervisor, Harry Kandinsky. Harry checked the adhesive coating machine and noticed that the temperature was set at 220 degrees. Apparently, an employee had set the temperature at a higher degree to clean the machine but forgot to reset it back to 190 degrees. The error was corrected but not without consequences. Klassy's had to destroy 5,000 sets of jewellery due to fading issues. This put production behind and Klassy's could not fulfill promised delivery time for important customers. Another issue that arose was another employee noticed that the adhesive coating machine was not using the required amount of coating. The worker measured the thickness of the coating being applied to the jewelry and concluded that the coating thickness was only 6.8 microns. A check of jewelry being dried and those being packaged for shipping revealed that their coating was also 6.8 microns. They were able to correct this issue but there was no way of determining how many sets of jewelry were shipped before the coating problem was discovered. The Customer Service Department The customer service office is responsible for pricing, entering in customer orders, tracking of orders, and ensuring orders are delivered on the promised delivery date to customers. If an issue on the shipping date occurs, it is the responsibility of the customer service office to contact the customer. This office also handles any customer complaints regarding the product or delivery service. As president of Klassy's, Krystal Jemmies visits her customers to ensure they are satisfied with their products. During one of these visits, Krystal encounters Ruby Safire, owner of Safire Jewelry. Ruby is quite upset and expressed her frustration to Krystal below: Krystal, I have been a loyal customer to you since you first opened your business. I understand that you have grown substantially over the years. With the intro of your new gemstone Royal jewelry line I am extremely happy that your business is even busier. I feel that the quality of your product has deteriorated and no one within your company seems to care. I contacted your customer service last Wednesday on an order I was supposed to receive on Monday. Can you believe that the order was not even ready to be shipped out? No one even had the decency to contact me. I was put on hold for over 5 minutes and finally someone answered. She did not identify herself, and she could not tell me the status of my order or even when I placed the order. It seems this person had just taken over the position and co not find the past order "notes". Why are there sticky notes for orders? Why are notes not pu computer under the client's name. Krystal, I have always been upfront with you and have been your customer for many years, but this treatment by your employees is unacceptable. I truly have reservations of continuing doing business with you. Krystal is so upset with Ruby's comments that she feels immediate action must be taken. She returned to the office and sent an email to her top 100 customers. In the email she asks them if they are having any customer service issues with her company. She received 78 responses from customers which are summarized below: PROBLEM NUMBER OF RESPONDENTS CITING PROBLEMS 18 4 57 Incorrect Pricing Lost Orders Did not notify customer with regards to a change in delivery date Did not know status of customer's order Order was incorrect-wrong product was shipped Slow response to inquirers Other problems, not listed above 71 3 83 12 Questions: 1. On which dimensions of quality does Klassy's compete? How are these dimensions being threatened by the problems in both the manufacturing and customer service? 2. What are the problems with the current manufacturing process as a whole and with the adhesive coating machine in particulor? How might you use process mapping and root cause analysis to get to the bottom of these issues? 3. Develop a Pareto chart based on the customer survey results for the customer service office. What seems to be the key problems? How might you use a PDCA cycle to go about resolving these problems? 4. Suppose the adhesive coating machine currently provides the following results: VARIABLE PROCESS MEAN PROCESS STANDARD DEVIATION Temperature 195 degrees 2.50 degrees Thickness 10 microns .047 microns Calculate the process capability ratio (Cp) for both the temperature and the thickness variables. Is the adhesive coating machine process able to meet the engineering standards 99.7% of the time? Explain

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts