Question: nit: 3:00:00 Time Left:2:59:02 Gurjot Singh Attempt 1 Case Study Mission Impastable: An improbable Supply Chain Success Story 2 3 5 6 8 9 Dan

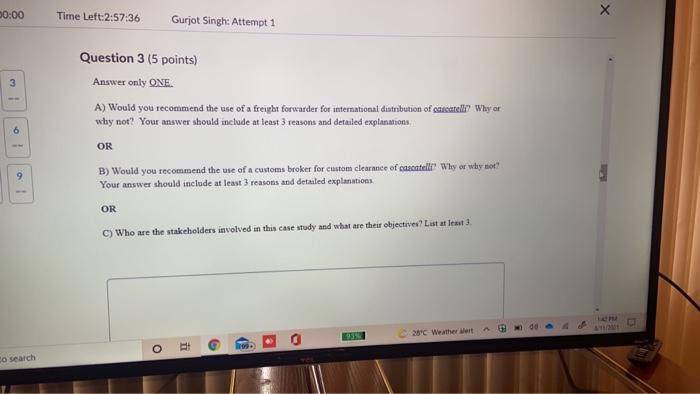

nit: 3:00:00 Time Left:2:59:02 Gurjot Singh Attempt 1 Case Study" Mission Impastable: An improbable Supply Chain Success Story" 2 3 5 6 8 9 Dan Pashman wanted to create his own pasta shape. After years of dreaming that he'd be the guy to add a new kind of pasta to your grocery store's selection, and then reporting on the quest through his podcast The Sporkful he was ready to launch cascatelli (from the Italian word for waterfall." which the pasta shape resembles) into the world last year. Then he ran into the COVID-19 pandemic. "Like many people, I'm accustomed to clicking a couple of buttons on my phone or computer and a package shows up on my doorstep in a few days," said Pashman, who had no previous food development experience. "I never thought about how many months of preparation and planning and movement of materials had to take place for that to happen." Pashman's "Mission ImPASTAble" the multi-part podcast series about making Cascatelli by Sporkful, encapsulates the supply chain hurdles businesses and manufacturers how faced sine March of last year. From not being able to find raw materials to make cry manufacturing parts, to having trouble sourcing paper for boxes in a more commerce-heavy world, tell has taken a bumpy road to get from Pashman's brain to your plate. Innovating to work around material shortages Pashman and his team hit their first roadblock in March 2020. He partnered with D. Mala Sons to make the pasta die, which is used to give the pasta its shape. But most hrunze red to e here to search Attempt 1 6 3 9 taken a bumpy road to get trom Pashman's brain to your plate. Innovating to work around material shortages Pashman and his team hit their first roadblock in March 2020. He partnered with D. Maldar & Sons to make the pasta die, which is used to give the pasta its shape. But most bronze (used to make the die) comes from Italy and the Middle East, said Pashman, areas that were both hard hit by COVID-19 early. Foundries were only running with skeleton crews For dies that could still be made, Pashman wasn't a priority customer. Because of a sudden demand for dried pasta at the start of the pandemic, pasta companies upped their production by 30%, according to Slate. Established companies came first, not one guy with a podcast trying to make a life-long dream come true - even if he does have a James Beard Award. Raw materials for dies usually took three to four weeks to get, but they were now taking more like three to four months," Pashman said. So Pashman got creative: He found an old die that wasn't used anymore. D. Maldari & Sons took out the inserts that made another pasta shape, and popped casetelli's in. That kind of supply chain innovation has kept companies going during the last 18 months, said Jonathan Eaton, national supply chain practice leader at Grant Thornton Supply chain disruption were "at an all-time high due to events like new tarifts, Brexit, the Texas winter storms and cybersecurity attacks that shut down an oil pipeline and meat processing facilities Businesses can't always immediately overcome hurdles like lack of capacity, labor or raw materials But they can use an old die to make a new one. "People are absolutely looking at innovative ways to overcome things like that," Eaton said. 200 Weather alert o to search VIVO x Limit: 3:00:00 Time Left:2:58:13 Gurjot Singh Attempt 1 ge 1: 2 3 4 5 6 B 7 8 9 "Other companies waiting for paper orders overseas... called up willing to spend more money and make bigger orders," said Pashman. Pashman could have overcome such future hurdles by partnering with a co-packer or distributor said Eaton. Those partners have the infrastructure and relationships to help buffer supply chain disruptions, and get products onto grocery store shelves. But Pashman decided to stick with Sfoglani and D. Maldari & Sons. They're currently focused on building up inventory to fill back orders (wait times for online orders is 12 weeks) and prepare for their first grocery store launch, in Fresh Market grocery stores in October, as well as in some restaurants Some complications wouldn't have been a bad thing for the podeast, said Pashman, "ectrom a storytelling perspective, you need drama and tension and there has to be struggle, there is not an interesting story," he said. But even he had his limits. "It all worked out in the end, and I learned a lot doing it," he added, including a new appreciation for the power, and hamstrings, of supply chaina Source: http://www.supplychaindice.comews/cascatelli porkful mission imputabile chain/604248/ Question 2 (5 points) Summarize the details of this case study focusing specifically on role and indertelt between the comments of internationalistes en fedt how they ti Type here to search Time Limit: 3:00:00 Time Left:2:58:30 Gurjot Singh Attempt 1 Page 1: 1 2 3 4 5 6 7 8 9 Boxed in by boxes Once the team which included pasta maker Sfoglini Pasta) had the shape and soured the right flour, they ran into another supply chain problem: finding paper to make boses. The adden rise in demand for online shopping had caused demand for corrugated cardboard to se Originally, Pashman wanted to make 5.000 16 oz. bones of cascatelli, to ship directly to consumers from the Sfoglini Pasta website. Because Sfoglini couldn't source enough material for bones, they only made 3.700 The pasta went for sale on the Sfoglini Pasta website on March 19, 2001. The whole 3.700 box rum sold out in less than two hours. Then the story went viral, with cascatelli appearing everywhere from The New York Times to Access Hollywood to Sarah Jessica Parker's Instagcam.feed. Onders kept pouring in To overcome the box issue, the team first made a few five pound bundles that they packaged in plastic and affixed with a label. That worked in a pinch, but those baga still had to be packaged by hand so it was not a good solution in the long term, sald Pashman. Instead of continuing to wait for that specific paper product, which made a rougher, recycled paper" look, Pashman said they switched to a different kind of paper that was easier to source. The newer boxes are shinier because of it The late March blockage of the Suez Canal didn't help either, even though their order was coming from an American supplier. Just like with the original pasta dir, Pashman and his small project pushed to the back of the shipping line relation willine tundma Other manier waitine in narrers were 20 Weather o B1 Type here to search 00:00 Time Left:2:57:36 Gurjot Singh: Attempt 1 Question 3 (5 points) 3 Answer only ONE A) Would you recommend the use of a freight forwarder for international distribution of cascatelli? Why ar why not? Your answer should include at least 3 reasons and detailed explanations 6 OR B) Would you recommend the use of a customs broker for custom clearance of cascatelli Why or why not? Your answer should include at least 3 reasons and detailed explanations OR C) Who are the stakeholders involved in this case study and what are their objectives List at least 3. 28 Weather Welt o ti ro o search nit: 3:00:00 Time Left:2:59:02 Gurjot Singh Attempt 1 Case Study" Mission Impastable: An improbable Supply Chain Success Story" 2 3 5 6 8 9 Dan Pashman wanted to create his own pasta shape. After years of dreaming that he'd be the guy to add a new kind of pasta to your grocery store's selection, and then reporting on the quest through his podcast The Sporkful he was ready to launch cascatelli (from the Italian word for waterfall." which the pasta shape resembles) into the world last year. Then he ran into the COVID-19 pandemic. "Like many people, I'm accustomed to clicking a couple of buttons on my phone or computer and a package shows up on my doorstep in a few days," said Pashman, who had no previous food development experience. "I never thought about how many months of preparation and planning and movement of materials had to take place for that to happen." Pashman's "Mission ImPASTAble" the multi-part podcast series about making Cascatelli by Sporkful, encapsulates the supply chain hurdles businesses and manufacturers how faced sine March of last year. From not being able to find raw materials to make cry manufacturing parts, to having trouble sourcing paper for boxes in a more commerce-heavy world, tell has taken a bumpy road to get from Pashman's brain to your plate. Innovating to work around material shortages Pashman and his team hit their first roadblock in March 2020. He partnered with D. Mala Sons to make the pasta die, which is used to give the pasta its shape. But most hrunze red to e here to search Attempt 1 6 3 9 taken a bumpy road to get trom Pashman's brain to your plate. Innovating to work around material shortages Pashman and his team hit their first roadblock in March 2020. He partnered with D. Maldar & Sons to make the pasta die, which is used to give the pasta its shape. But most bronze (used to make the die) comes from Italy and the Middle East, said Pashman, areas that were both hard hit by COVID-19 early. Foundries were only running with skeleton crews For dies that could still be made, Pashman wasn't a priority customer. Because of a sudden demand for dried pasta at the start of the pandemic, pasta companies upped their production by 30%, according to Slate. Established companies came first, not one guy with a podcast trying to make a life-long dream come true - even if he does have a James Beard Award. Raw materials for dies usually took three to four weeks to get, but they were now taking more like three to four months," Pashman said. So Pashman got creative: He found an old die that wasn't used anymore. D. Maldari & Sons took out the inserts that made another pasta shape, and popped casetelli's in. That kind of supply chain innovation has kept companies going during the last 18 months, said Jonathan Eaton, national supply chain practice leader at Grant Thornton Supply chain disruption were "at an all-time high due to events like new tarifts, Brexit, the Texas winter storms and cybersecurity attacks that shut down an oil pipeline and meat processing facilities Businesses can't always immediately overcome hurdles like lack of capacity, labor or raw materials But they can use an old die to make a new one. "People are absolutely looking at innovative ways to overcome things like that," Eaton said. 200 Weather alert o to search VIVO x Limit: 3:00:00 Time Left:2:58:13 Gurjot Singh Attempt 1 ge 1: 2 3 4 5 6 B 7 8 9 "Other companies waiting for paper orders overseas... called up willing to spend more money and make bigger orders," said Pashman. Pashman could have overcome such future hurdles by partnering with a co-packer or distributor said Eaton. Those partners have the infrastructure and relationships to help buffer supply chain disruptions, and get products onto grocery store shelves. But Pashman decided to stick with Sfoglani and D. Maldari & Sons. They're currently focused on building up inventory to fill back orders (wait times for online orders is 12 weeks) and prepare for their first grocery store launch, in Fresh Market grocery stores in October, as well as in some restaurants Some complications wouldn't have been a bad thing for the podeast, said Pashman, "ectrom a storytelling perspective, you need drama and tension and there has to be struggle, there is not an interesting story," he said. But even he had his limits. "It all worked out in the end, and I learned a lot doing it," he added, including a new appreciation for the power, and hamstrings, of supply chaina Source: http://www.supplychaindice.comews/cascatelli porkful mission imputabile chain/604248/ Question 2 (5 points) Summarize the details of this case study focusing specifically on role and indertelt between the comments of internationalistes en fedt how they ti Type here to search Time Limit: 3:00:00 Time Left:2:58:30 Gurjot Singh Attempt 1 Page 1: 1 2 3 4 5 6 7 8 9 Boxed in by boxes Once the team which included pasta maker Sfoglini Pasta) had the shape and soured the right flour, they ran into another supply chain problem: finding paper to make boses. The adden rise in demand for online shopping had caused demand for corrugated cardboard to se Originally, Pashman wanted to make 5.000 16 oz. bones of cascatelli, to ship directly to consumers from the Sfoglini Pasta website. Because Sfoglini couldn't source enough material for bones, they only made 3.700 The pasta went for sale on the Sfoglini Pasta website on March 19, 2001. The whole 3.700 box rum sold out in less than two hours. Then the story went viral, with cascatelli appearing everywhere from The New York Times to Access Hollywood to Sarah Jessica Parker's Instagcam.feed. Onders kept pouring in To overcome the box issue, the team first made a few five pound bundles that they packaged in plastic and affixed with a label. That worked in a pinch, but those baga still had to be packaged by hand so it was not a good solution in the long term, sald Pashman. Instead of continuing to wait for that specific paper product, which made a rougher, recycled paper" look, Pashman said they switched to a different kind of paper that was easier to source. The newer boxes are shinier because of it The late March blockage of the Suez Canal didn't help either, even though their order was coming from an American supplier. Just like with the original pasta dir, Pashman and his small project pushed to the back of the shipping line relation willine tundma Other manier waitine in narrers were 20 Weather o B1 Type here to search 00:00 Time Left:2:57:36 Gurjot Singh: Attempt 1 Question 3 (5 points) 3 Answer only ONE A) Would you recommend the use of a freight forwarder for international distribution of cascatelli? Why ar why not? Your answer should include at least 3 reasons and detailed explanations 6 OR B) Would you recommend the use of a customs broker for custom clearance of cascatelli Why or why not? Your answer should include at least 3 reasons and detailed explanations OR C) Who are the stakeholders involved in this case study and what are their objectives List at least 3. 28 Weather Welt o ti ro o search